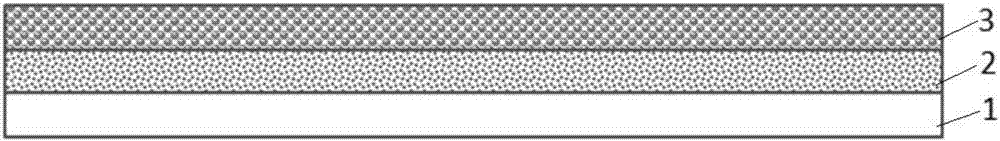

Polymer composite lithium battery diaphragm and preparation method thereof

A battery separator and polymer technology, applied in the field of polymer composite lithium battery separator and its preparation, can solve the problems of increased thermal shrinkage of the separator, powder dropping of inorganic particles, failure of binder, etc., so as to avoid electrolyte leakage and enhance Temperature resistance, solve the effect of falling powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

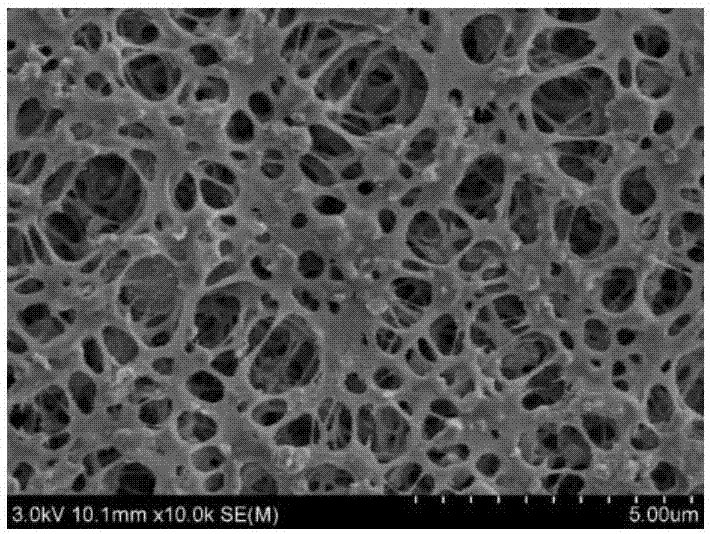

Embodiment 1

[0030] The high temperature resistant resin in this example is meta-aromatic polyamide (abbreviated as PMIA), the inorganic particles are made of alumina ceramic powder with purity greater than 99.99% and D50 of 0.6μm, and the solvent is N,N-dimethylacetamide (DMAc). ), the poor solvent is tripropylene glycol (TPG), the resin cosolvent is lithium chloride (LiCl), the stabilizer is propylene carbonate, and the binder is homopolyvinylidene fluoride with a molecular weight greater than 600,000.

[0031] The preparation of the coating slurry for the high-temperature resistant lithium composite battery separator in this example: firstly disperse tripropylene glycol and alumina ceramic powder with a mass ratio of 3:2, and then add them to dissolve in N,N-dimethylacetamide The mass ratio of PMIA to alumina ceramic powder in the PMIA glue is 1:3, then add an appropriate amount of LiCl, propylene carbonate and homopolyvinylidene fluoride, and mix well to obtain a slurry with a viscosity of...

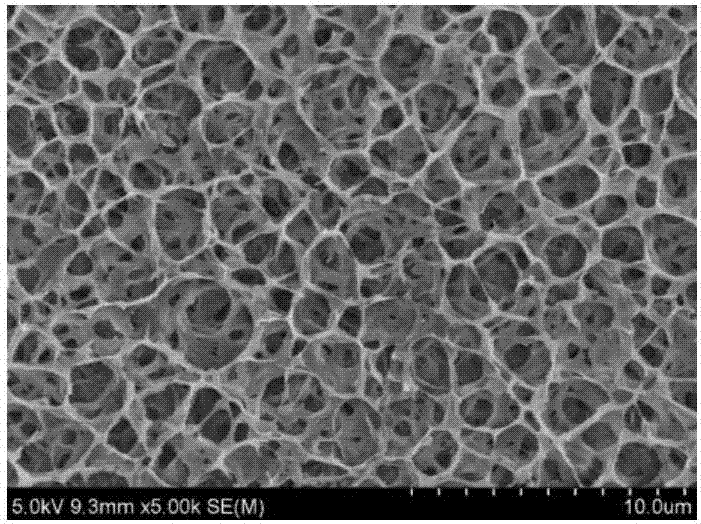

Embodiment 2

[0039] The preparation of the coating slurry and the composite battery separator of this example is the same as that of Example 1. The base film is a single-layer PP film with a thickness of 12 μm prepared by Shenzhen Zhongxing Innovative Material Technology Co., Ltd.

[0040] After the coating slurry is prepared, the coating slurry is coated on one of the surfaces of the PP film by the gravure roll method. Next, the obtained film was placed in a temperature and humidity environment with a temperature of 70° C. and a relative humidity of 80-90% to preliminarily precipitate and solidify the high-temperature resistant resin; the preliminarily precipitated and solidified film used the same coagulation bath as in Example 1. Water washing and drying conditions are processed to obtain the base film with the inorganic particle coating of this example.

[0041] The polyvinylidene fluoride particles are suspended and dispersed in deionized water to prepare a polymer resin particle suspensio...

Embodiment 3

[0045] The preparation of the coating slurry and the composite battery separator of this example is the same as that of Example 1. The base film is a single-layer PP film with a thickness of 12 μm prepared by Shenzhen Zhongxing Innovative Material Technology Co., Ltd.

[0046] After the coating slurry is prepared, the coating slurry is coated on one of the surfaces of the PP film by the gravure roll method. Next, the obtained film was placed in the same temperature and humidity environment as in Example 2 for precipitation curing. Then, a 60m air-floating hot-air oven was used for drying at 70°C, and the membrane water remaining out of the box was less than 200 ppm, and the base film with the inorganic particle coating of this example was obtained.

[0047] The vinylidene fluoride-hexafluoropropylene polymer particles are suspended and dispersed in N-methylpyrrolidone to prepare a polymer resin particle suspension slurry with a viscosity of 8 cP and a slurry solid content of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com