Device and method for pretreatment of biological natural gas synthesis through coupling between brown coal base and biomass

A technology for synthesizing biomass and biomass, which is applied in the fields of biofuel, production of combustible gas, gasification process, etc., can solve the problem of lignite powder economy, poor environmental protection, inability to effectively reduce gas sulfur content, affecting methanation efficiency and cost, etc. To reduce the risk of deactivation, reduce the overall cost of gas production, and reduce the cost of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail.

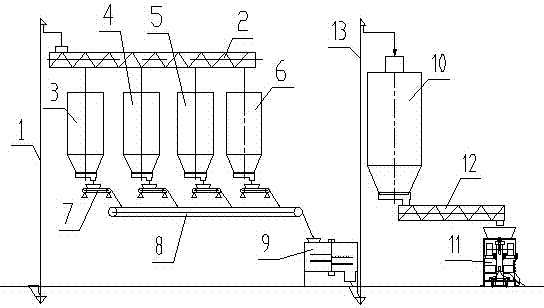

[0020] Such as figure 1 As shown, the pretreatment device for synthesizing bio-natural gas based on lignite and biomass in this embodiment includes a connected elevator 1 and a material distribution screw conveyor 2, and each outlet of the material distribution screw conveyor 2 is connected with the lignite powder respectively. The inlets of bin 3, straw powder bin 4, charcoal powder bin 5 and calcium oxide bin 6 are connected, and the outlets of the above four bins 3 to 6 are connected with a collection belt conveyor 8 through their respective electronic belt scales 7 , the belt conveyor 8 is connected in sequence with the mixer 9, the rotary discharge bin 10, the derived fuel granulator 11 and the gasifier 12 in sequence, wherein a lift is provided between the mixer 9 and the rotary discharge bin 10 machine 13, a screw conveyor 12 is provided between the rotary unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com