Graphene-Re-TiO2 multi-component nanotube material preparation method

A multi-component composite and nanotube technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of increasing production cost, low crystallinity, increasing equipment investment, etc., reducing equipment requirements and increasing specific surface area. , the effect of reducing the water heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

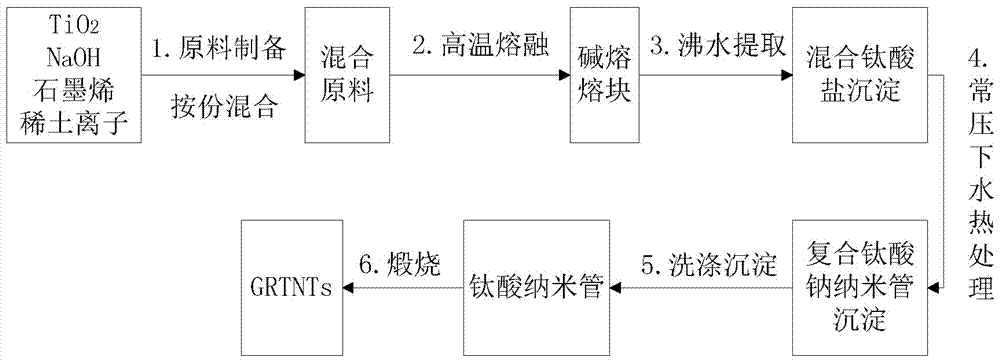

[0040] Such as figure 1 As shown, a graphene-Re-TiO 2 The preparation method of multiple composite nanotube material comprises the following steps:

[0041] Step 1: Preparation of mixed ingredients:

[0042] Commercially available nanoparticle TiO 2 Weigh it with NaOH raw material according to the mass ratio of 1:8, and pour it into the corundum crucible; then weigh the graphene powder and the rare earth compound with a mass percentage of 0.01-10.0wt%, and place them in the corundum crucible, and mix them thoroughly. Uniform, standby; wherein the metal ion Re in the rare earth compound 3+ 0.01~5.0%;

[0043] Step 2: high temperature melting:

[0044] At room temperature, place the above-mentioned corundum crucible with mixed raw materials in a vacuum high-temperature furnace isolated from air, and close the furnace door;

[0045] Open the argon gas flow valve, and pass in argon gas for 30-120 minutes to remove the air in the furnace body;

[0046] Raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com