A g-c that rapidly degrades pollutants 3 no 4 Composite photocatalyst and preparation method thereof

A rapid degradation, g-c3n4 technology, applied in the direction of physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve the problems of inability to quickly degrade water pollutants, and achieve good light absorption capacity and reactive sites The effect of increasing and speeding up the separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

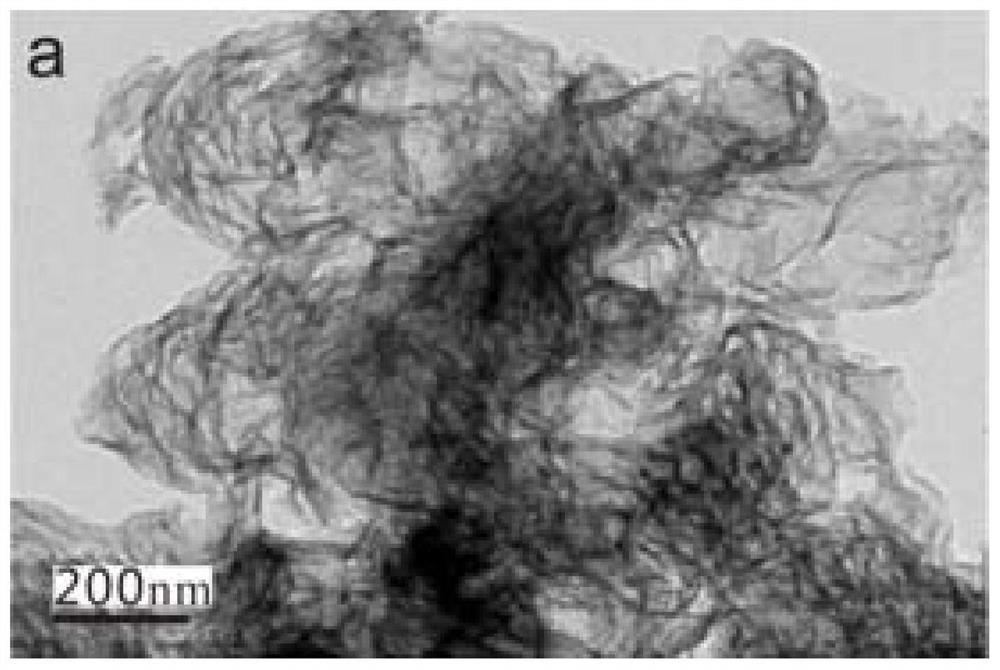

[0030] g-C in this example 3 N 4 Composite photocatalyst, using raw material g-C 3 N 4 and hydrogen peroxide solution, wherein, in mg / mL, g-C 3 N 4 The mass / volume ratio with hydrogen peroxide solution is 6:1, and the concentration of hydrogen peroxide is 30%.

[0031] Preparation of pure g-C 3 N 4 The process is: put urea into the crucible, put the lid on and put it into a muffle furnace for calcination at 500°C for 2 hours, the initial temperature is 20°C, and the heating rate is 5°C / min. 3 N 4 Powder.

[0032] Prepare above-mentioned g-C in the present embodiment 3 N 4 The composite photocatalyst is as follows: the above g-C 3 N 4Put 0.15g of powder into a 50mL single-necked flask, add 25mL of hydrogen peroxide solution, place the flask in an oil bath, install a condenser tube, turn on the water circulation, turn on the magnetic stirring, set the temperature of the oil bath to 110°C, and the reflux time 6h, after the reaction was completed, the solution was tak...

Embodiment 2

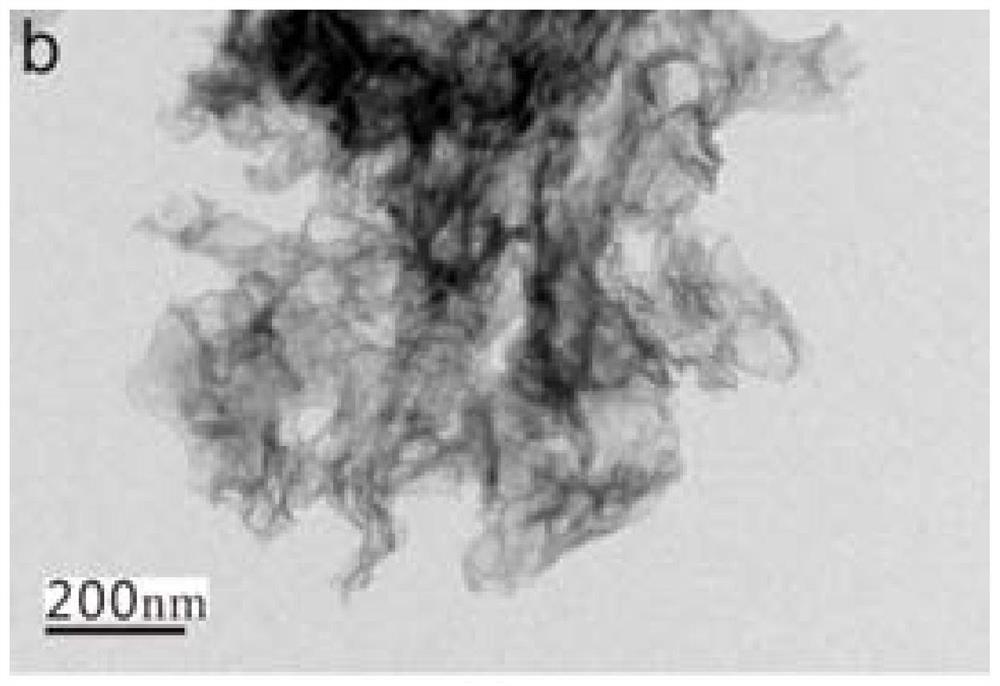

[0034] g-C in this example 3 N 4 Composite photocatalyst, using raw material g-C 3 N 4 and hydrogen peroxide solution, wherein, in mg / mL, g-C 3 N 4 The mass / volume ratio with hydrogen peroxide solution is 6:1, and the concentration of hydrogen peroxide is 30%.

[0035] Preparation of pure g-C 3 N 4 The process is: put urea into the crucible, put the lid on and put it in a muffle furnace for calcination at 500°C for 2.5h, the initial temperature is 20°C, the heating rate is 10°C / min, after the calcination is completed, cool naturally to room temperature, take out the sample to obtain pure g-C 3 N 4 Powder.

[0036] Prepare above-mentioned g-C in the present embodiment 3 N 4 The composite photocatalyst is as follows: the above g-C 3 N 4 Put 0.15g of powder into a 50mL single-necked flask, add 25mL of hydrogen peroxide solution, place the flask in an oil bath, turn on the magnetic stirring, add 0.25mL of tetrabutyl titanate solution drop by drop, install the condenser...

Embodiment 3

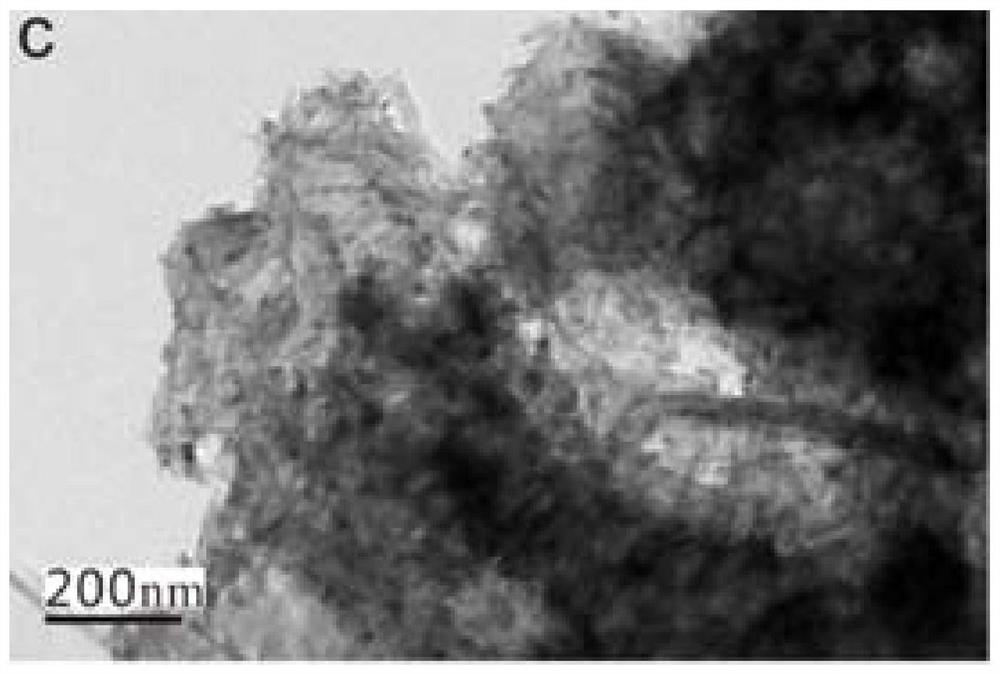

[0038] g-C in this example 3 N 4 Composite photocatalyst, using raw material g-C 3 N 4 and hydrogen peroxide solution, wherein, in mg / mL, g-C 3 N 4 The mass / volume ratio with hydrogen peroxide solution is 6:1, and the concentration of hydrogen peroxide is 30%.

[0039] Preparation of pure g-C 3 N 4 The process is: put urea into the crucible, put the lid on and put it in a muffle furnace for calcination at 500°C for 2.5h, the initial temperature is 20°C, the heating rate is 10°C / min, after the calcination is completed, cool naturally to room temperature, take out the sample to obtain pure g-C 3 N 4 Powder.

[0040] Prepare above-mentioned g-C in the present embodiment 3 N 4 The composite photocatalyst is as follows: the above g-C 3 N 4 Put 0.15g of powder into a 50mL single-necked flask, add 25mL of hydrogen peroxide solution, place the flask in an oil bath, turn on magnetic stirring, add 1mL of tetrabutyl titanate solution drop by drop, install a condenser tube, tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com