Method for catalytic synthesis of sodium tetrathionate with loaded iodine

A technology of sodium tetrasulfate and elemental iodine, applied in the field of preparation of sodium tetrasulfate, can solve the problems of many side reactions, pollution, low yield and the like, and achieve the effects of avoiding toxicity, high reaction efficiency and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

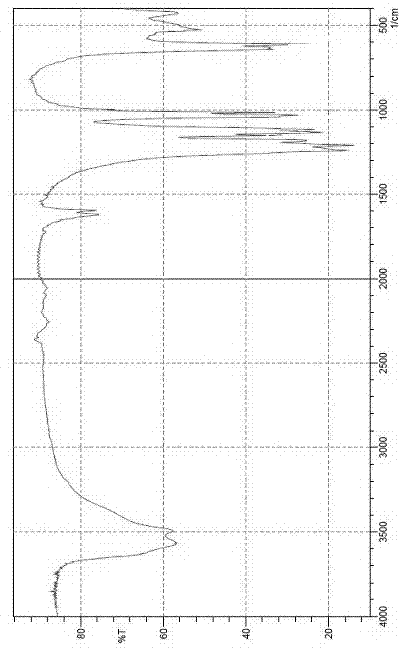

Image

Examples

Embodiment 1

[0016] Example 1 The preparation method of activated carbon supported elemental iodine

[0017] Weigh the activated carbon that has been dried to constant weight and add it to 2.5% ethanol solution of iodine, stir at room temperature, filter with suction, rinse with ethanol several times until neutral, dry at 70°C to constant weight, put it in a desiccator, and weigh it after cooling. Weight, calculate the load. i.e. iodine loading = (W 1 -W) / W 1 ×100%, where: W 1 is the mass (g) of activated carbon after loading, and W is the mass (g) of activated carbon before loading.

Embodiment 2

[0018] Embodiment 2 The preparation method of chitosan loaded elemental iodine

[0019] Weigh chitosan dried to constant weight and add 2.5% iodine ethanol solution, stir at room temperature, filter with suction, rinse with ethanol several times until neutral, dry at 70°C to constant weight, put in a desiccator, Cool and weigh and calculate the load. i.e. iodine loading = (W 1 -W) / W 1 ×100%, where: W 1 W is the mass (g) of chitosan after loading, and W is the mass (g) of chitosan before loading.

Embodiment 3

[0020] Example 3 Preparation method of silica gel loaded elemental iodine

[0021] Weigh 200-300 meshes of silica gel dried to constant weight and add it to 2.5% iodine ethanol solution, stir at room temperature, filter with suction, rinse with ethanol several times until neutral, dry at 70°C to constant weight, and put it in a desiccator , cooling and weighing, and calculating the load. i.e. iodine loading = (W 1 -W) / W 1 ×100%, where: W 1 is the mass (g) of silica gel after loading, and W is the mass (g) of silica gel before loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com