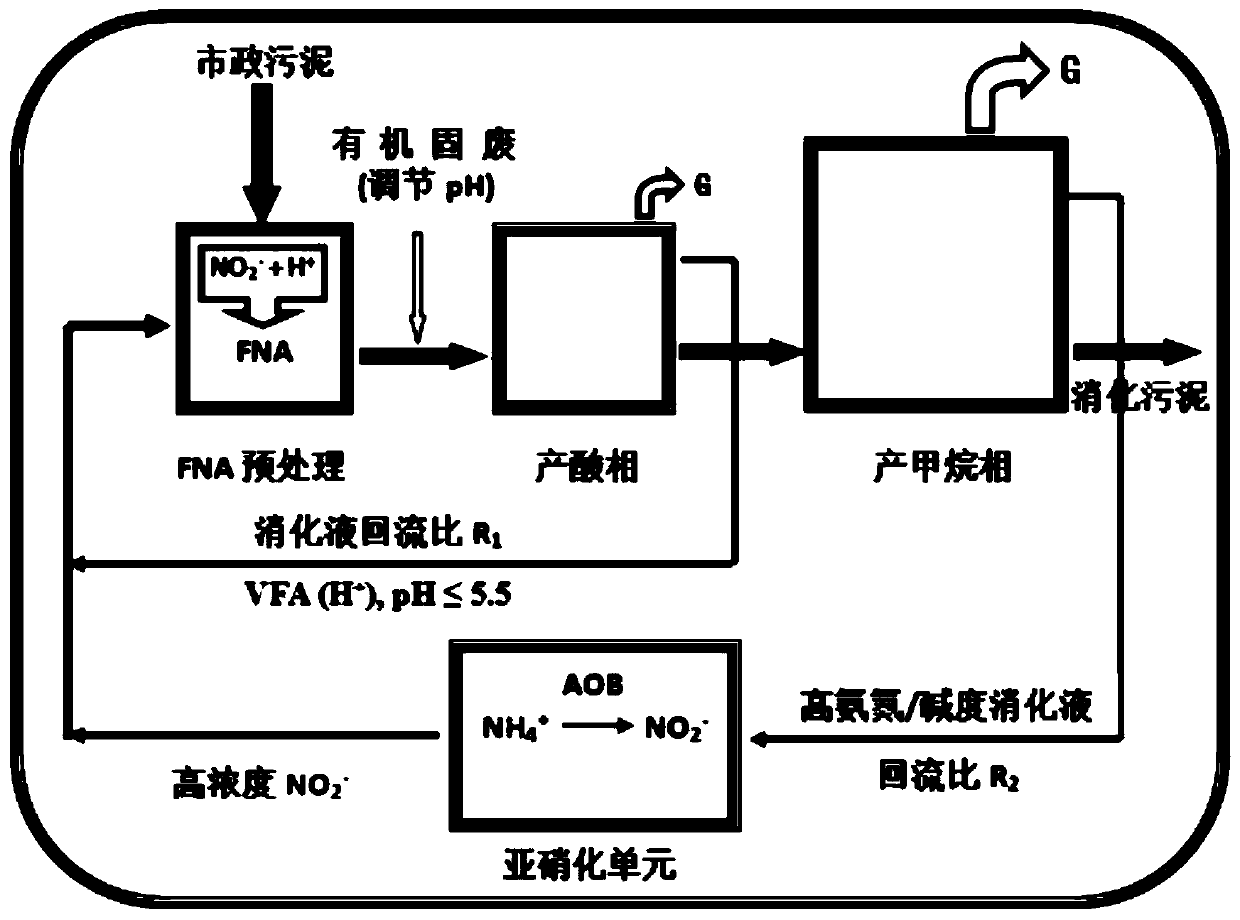

A kind of endogenous FNA pretreatment sludge reduction and resource recovery process

A sludge reduction and pretreatment technology, applied in sludge treatment, biological sludge treatment, special treatment targets, etc., can solve the problems of increasing the cost of biochemical synthesis of FNA, and achieve sludge reduction and resource utilization, The effect of reducing production cost and improving hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Using the above-mentioned coupling process, the remaining activated sludge with a water content of 98% in urban sewage plants is used as the treatment object, and kitchen waste with a water content of 90% is added before the acid production phase (according to kitchen waste and remaining active sludge) The volume ratio of sludge is 1:5), the temperature of the acid-producing phase reactor is controlled at 55±0.5°C, the temperature of the methanogenic phase is controlled at 35±0.5°C, and the effective volume ratio of the acid-producing phase and the methanogenic phase is 1: 6. When the hydraulic retention time HRT=15d, at this time, the pH of the acid production phase is 5.5, the concentration of nitrite nitrogen in the subdigestion unit is 710 mg / L, and the concentration of FNA synthesized by the FNA pretreatment unit is about 1.78 mg HNO 2 -N / L, after the stable operation of 3 HRTs, compared with the two-phase anaerobic digestion process without FNA pretreatment, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com