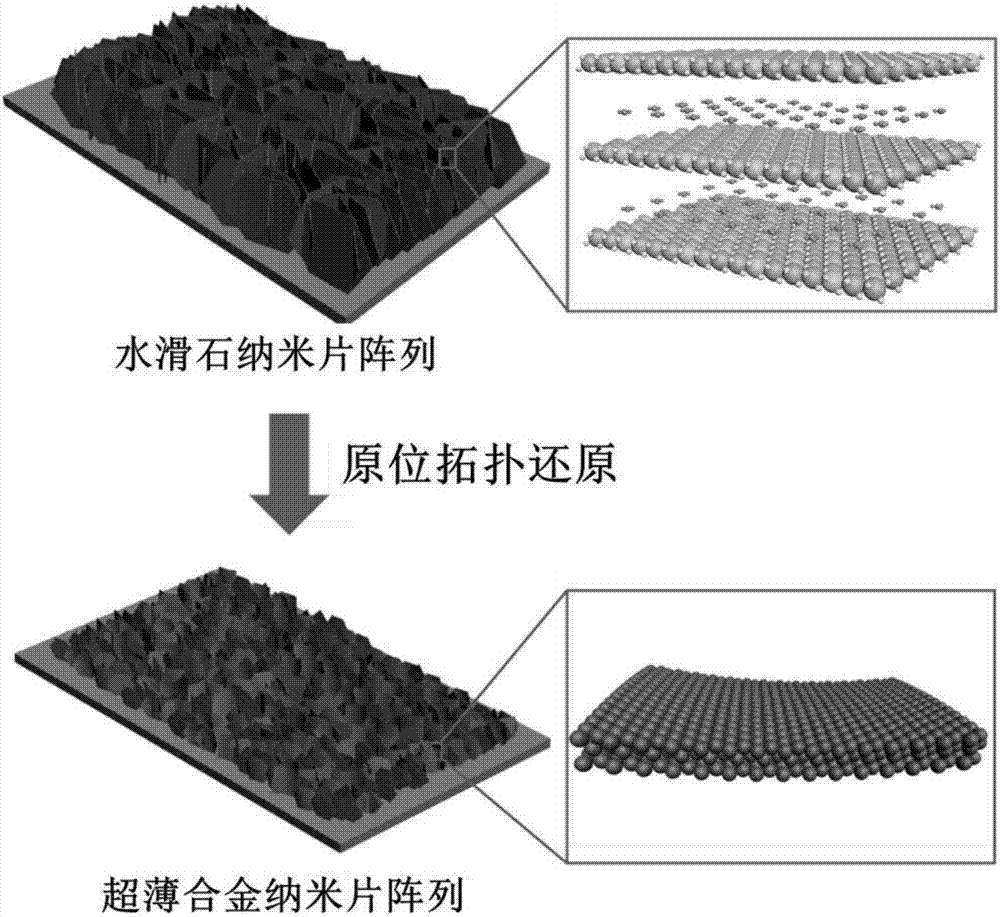

Preparation method for synthesizing ultra-thin metal alloy nanosheet array material by means of hydrotalcite topological transformation

A nanosheet array and alloy nanotechnology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as the difficulty in the synthesis of ultra-thin two-dimensional metal nanosheets, avoid poor contact, and increase the ratio The effect of uniform surface area and material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

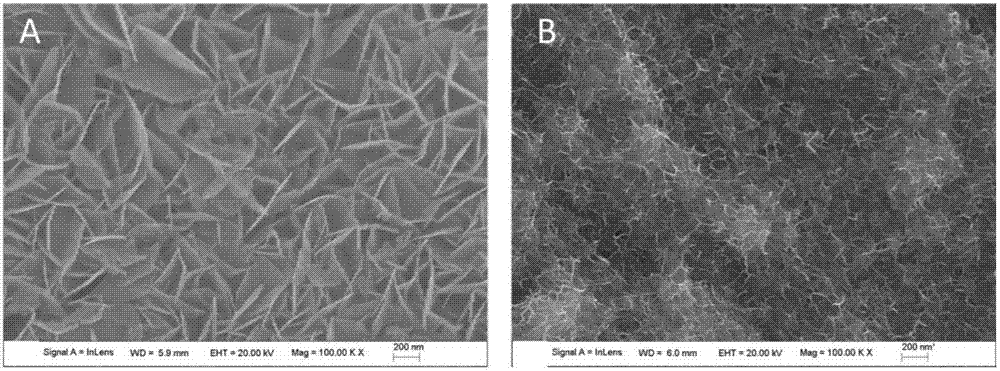

[0059] a. the foamed nickel base of acid treatment is put into the first reaction kettle obliquely, then add the nickel nitrate that comprises 0.12 mol / liter in this reaction kettle, the iron nitrate of 0.12 mol / liter, the urea of 1.5 mol / liter Aqueous solution, then close the reaction kettle, raise the temperature to 120°C and keep it under autogenous pressure for 12 hours to carry out the first hydrothermal reaction, so as to grow nickel-iron hydrotalcite nanosheet arrays perpendicular to the substrate on the surface of the nickel foam substrate;

[0060] b. take out the nickel foam substrate, wash and dry;

[0061] c. The nickel-iron hydrotalcite nanosheet array substrate treated in step b is placed obliquely into the second reaction kettle, and then a solution containing sodium hydroxide in ethylene glycol with a concentration of 0.625 mol / liter is added to the reaction kettle , sealing the reaction kettle, raising the temperature to 160° C. and maintaining it under auto...

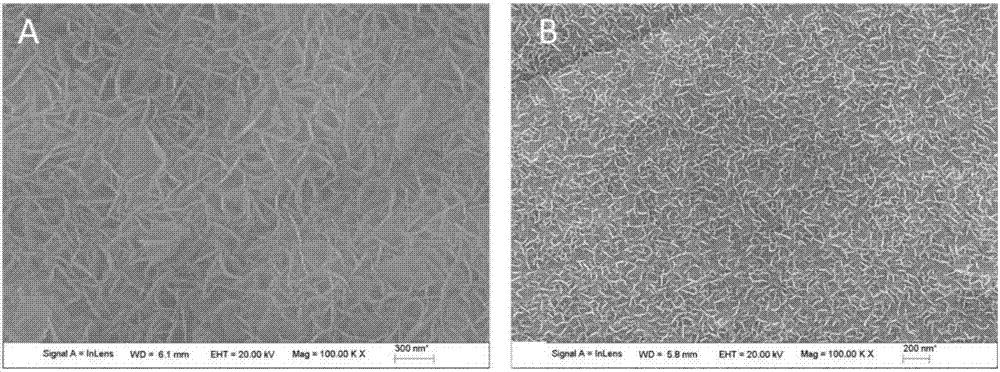

Embodiment 2

[0064] Referring to the method in Example 1, the nickel foam substrate is replaced with a copper foam substrate.

Embodiment 3

[0066] Referring to method in embodiment 1, change nickel nitrate into nickel chloride, ferric nitrate into ferric chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com