Full color OLED micro-display device manufacturing method

A technology for micro-display devices and display devices, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of low product yield, wafer stress damage, and high resolution, and achieves improved productivity and good products. efficiency, reduce production costs, and improve resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

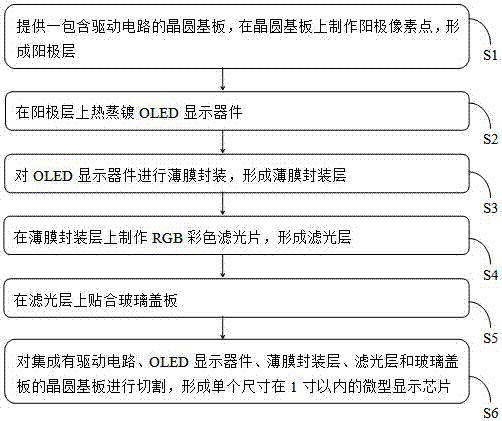

[0039] In the present embodiment, the production method of full-color OLED microdisplay device comprises the following steps:

[0040] A wafer substrate including a driving circuit is provided, and anode pixel points are fabricated on the wafer substrate to form an anode layer. The anode pixels are formed by evaporation, and the ambient vacuum is less than 10 -4 Pa, the material is selected from Cu. The OLED display device is thermally evaporated on the anode layer, and the OLED display device includes at least a light-emitting layer and a cathode layer, wherein the cathode layer is a semi-transparent structure; the OLED display device is thin-film encapsulated to form a thin-film encapsulation layer, the The thin film encapsulation layer is formed by alternately depositing multiple layers of organic or inorganic materials. The organic material of the thin film encapsulation layer is selected from polyacrylic acid, and the inorganic material is selected from Al 2 o 3 Making...

Embodiment 2

[0042] In the present embodiment, the production method of full-color OLED microdisplay device comprises the following steps:

[0043] A wafer substrate including a driving circuit is provided, and anode pixel points are fabricated on the wafer substrate to form an anode layer. The anode pixels are formed by evaporation, and the ambient vacuum is less than 10 -4 Pa, the material is selected from Al. An OLED display device is thermally evaporated on the anode layer, and the OLED display device at least includes a light-emitting layer and a cathode layer, wherein the cathode layer is a translucent structure. The OLED display device is encapsulated with a thin film to form a thin film encapsulation layer. The thin film encapsulation layer is formed by alternately depositing multiple layers of organic or inorganic materials. The organic material of the thin film encapsulation layer is selected from polyurethane acrylate, polyester, and the inorganic material is selected from from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com