A low-temperature lithium-ion battery negative electrode sheet for mobile base stations, preparation method, and lithium-ion battery

A technology for lithium-ion batteries and mobile base stations, applied in the field of lithium-ion batteries, can solve the problems of poor low-temperature performance of negative electrode sheets, achieve good low-temperature charge-discharge performance, meet application requirements, and improve low-temperature electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

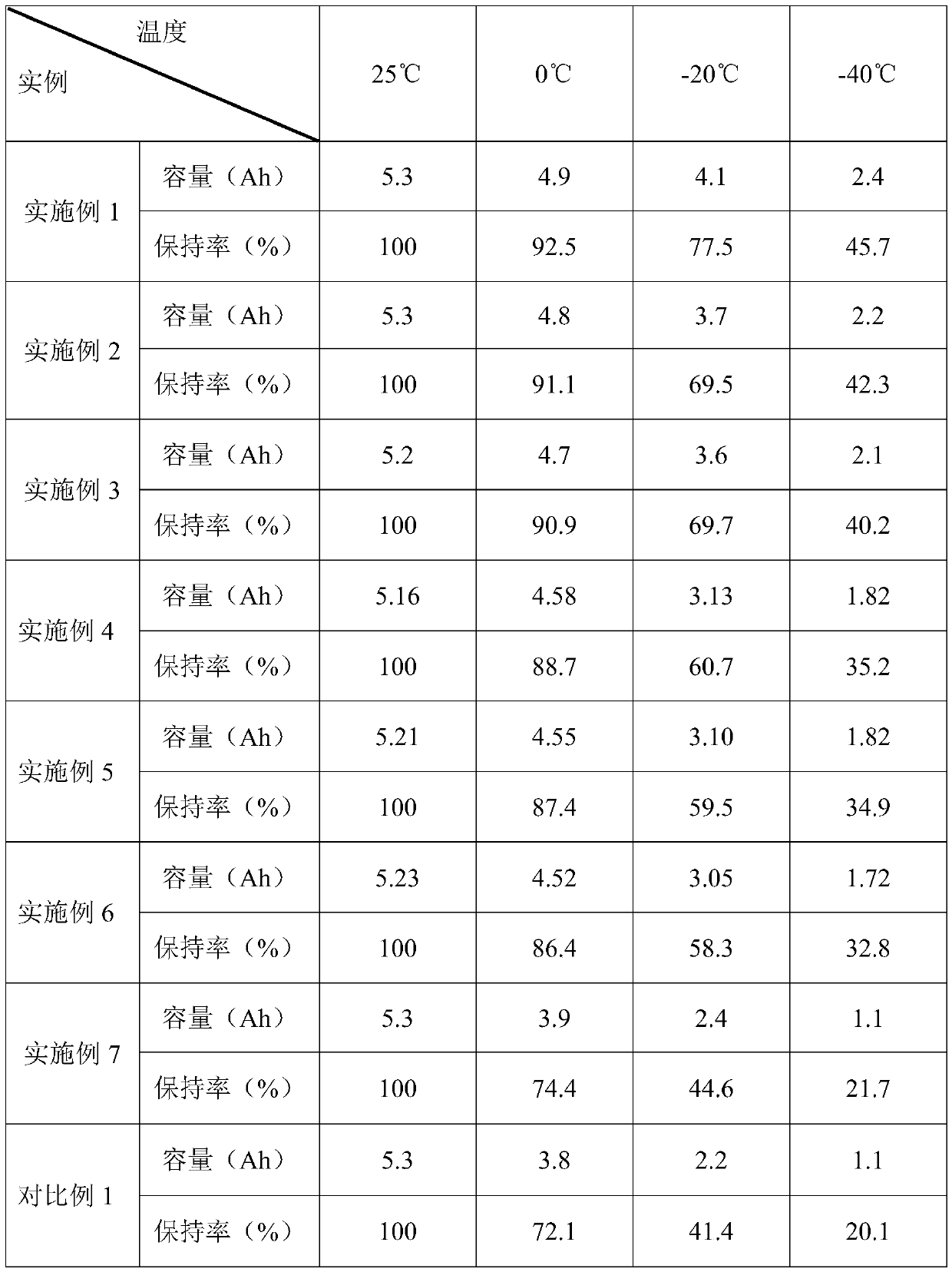

Embodiment 1

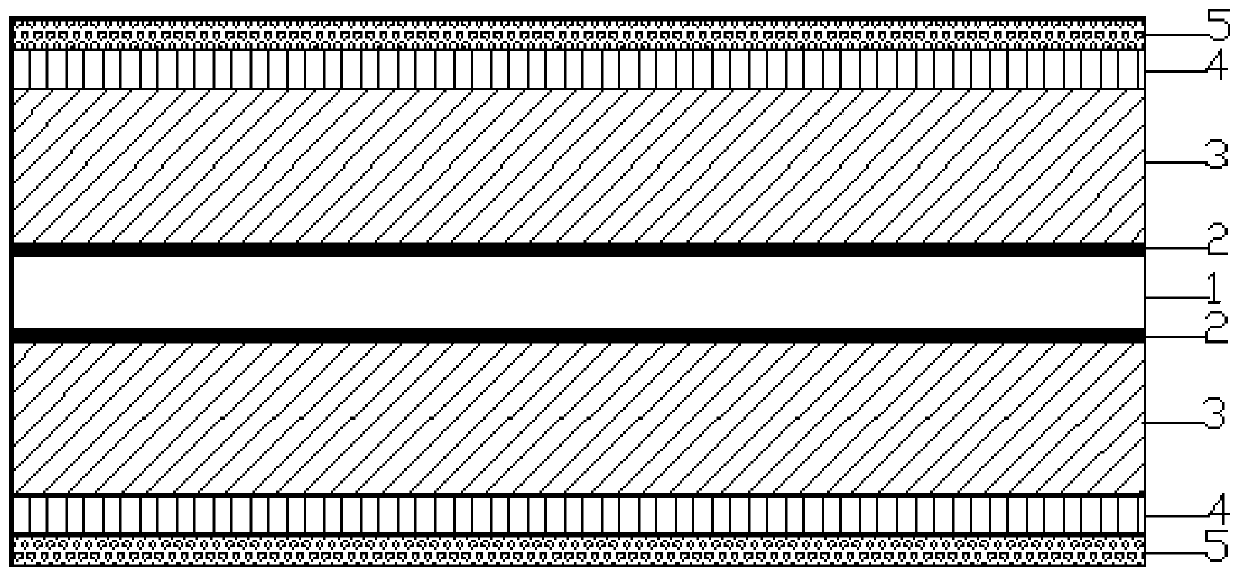

[0034] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations of this embodiment has a schematic structural diagram as figure 1 As shown, it includes a current collector (copper foil) 1 and a conductive layer 2, an active material layer 3, a solid electrolyte layer 4, and an energy storage functional layer 5 that are sequentially arranged on both sides of the current collector 1 along the direction away from the thickness of the current collector; the conductive layer consists of Composed of three-dimensional carbon material and polyvinylidene fluoride, the mass ratio of three-dimensional carbon material and polyvinylidene fluoride is 70:30; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94: 1:5; the solid electrolyte layer is composed of solid electrolyte Li 5 La 3 Ta 2 o 12 , carbon nanotubes, polyvinylidene fluoride, the mass ratio of the three is 3:...

Embodiment 2

[0043] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations in this embodiment has the same structure as in Embodiment 1, wherein the conductive layer is composed of a three-dimensional carbon material and polyvinylidene fluoride, and the mass ratio of the three-dimensional carbon material and polyvinylidene fluoride is 80:20; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94:1:5; the solid electrolyte layer is composed of solid electrolyte Li 5 La 3 Nb 2 o 12 , graphene, polyvinylidene fluoride, the mass ratio of the three is 1:1:10; the energy storage functional layer is composed of pentaerythritol phosphate melamine salt, graphene, polyvinylidene fluoride, and the mass ratio of the three is 1: 1:10.

[0044] The preparation method of the low-temperature lithium-ion battery negative electrode sheet for mobile base stations of the present embodiment ...

Embodiment 3

[0052] The low-temperature lithium-ion battery negative electrode sheet for mobile base stations in this embodiment has the same structure as in Embodiment 1, wherein the conductive layer is composed of a three-dimensional carbon material and polyvinylidene fluoride, and the mass ratio of the three-dimensional carbon material and polyvinylidene fluoride is 60:40; the active material layer is composed of graphite, SP conductive agent and polyvinylidene fluoride, and the mass ratio of the three is 94:1:5; the solid electrolyte layer is composed of solid electrolyte Li 6 BaLa 2 Ta 2 o 12 , gas phase growth carbon fiber, polyvinylidene fluoride, the mass ratio of the three is 5:5:20; the energy storage functional layer is composed of ammonium polyphosphate, vapor phase growth carbon fiber, polyvinylidene fluoride, the mass ratio of the three is 5 :5:20.

[0053] The preparation method of the low-temperature lithium-ion battery negative electrode sheet for mobile base stations o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com