High-rate capacity power battery electrolyte

A power battery, high-capacity technology, applied in the field of lithium batteries, can solve the problems of unsuitability for large-scale applications, high crown ether toxicity, adverse side reactions, etc., to improve high-rate cycle performance, optimize chemical composition, and improve transmission kinetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

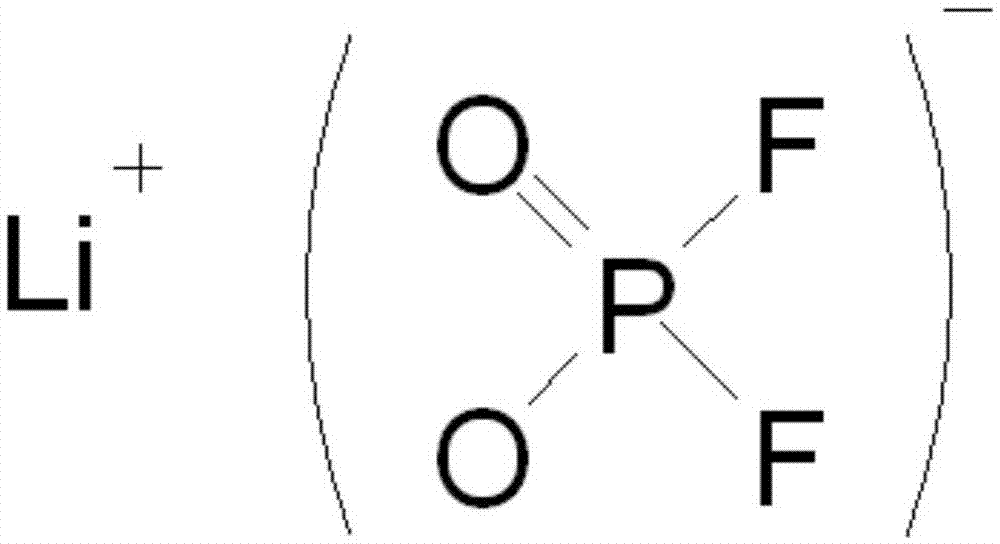

[0021] Example 1: At room temperature, in a glove box filled with argon, ethylene carbonate (EC), dimethyl carbonate (DMC), and ethyl acetate (EA) were mixed according to a mass ratio of 1:2:1, and Add 2% by mass of vinylene carbonate (VC) and 1% lithium difluorophosphite (LiDFP), then add lithium salt lithium hexafluorophosphate LiPF6 to dissolve to a concentration of 1.1mol / L, and prepare electrolyte 1.

Embodiment 2

[0022] Example 2: At room temperature, in a glove box filled with argon, ethylene carbonate (EC), dimethyl carbonate (DMC), and ethyl acetate (EA) were mixed according to a mass ratio of 1:2:1, and Add vinylene carbonate (VC) with a mass percentage of 2%, and then add lithium salt lithium hexafluorophosphate LiPF6 to dissolve to a concentration of 1.1 mol / L, and prepare electrolyte 2.

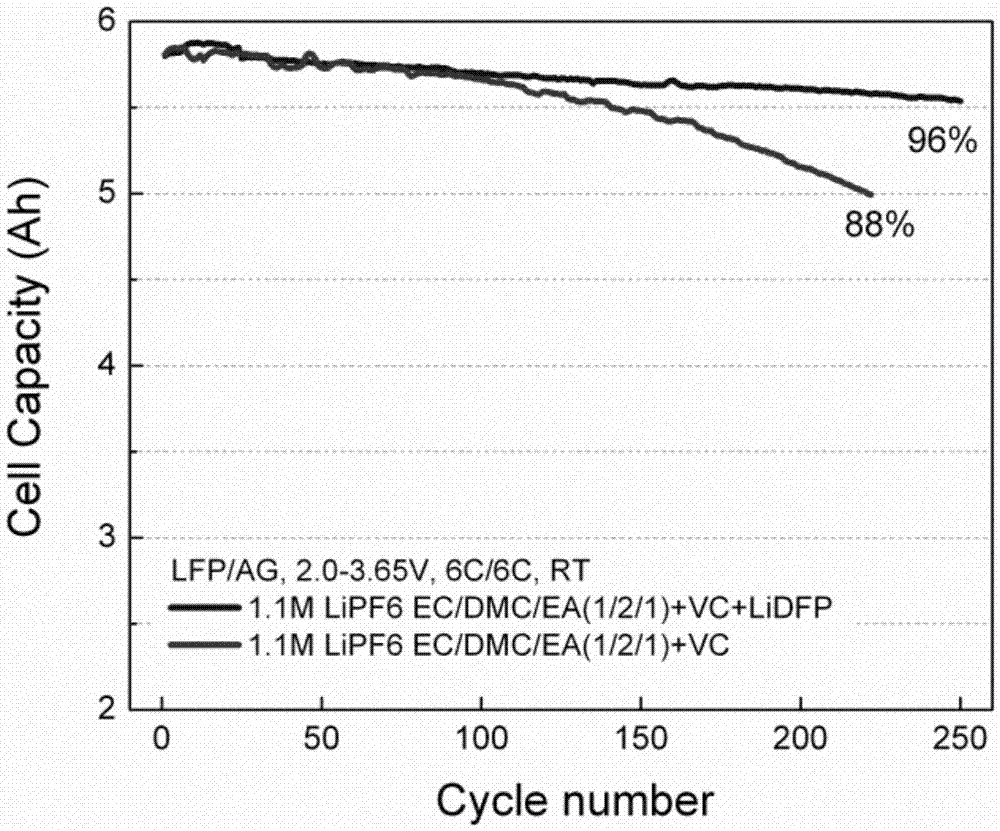

[0023] Use lithium iron as the positive electrode, graphite as the negative electrode, and the negative electrode compaction ≥ 1.60g / cm3, and use the electrolytes of Examples 1 and 2 to assemble a cylindrical full battery, with a capacity of 5.8Ah and a 6C current for rate charge and discharge cycles. The measurement results are as follows image 3 shown.

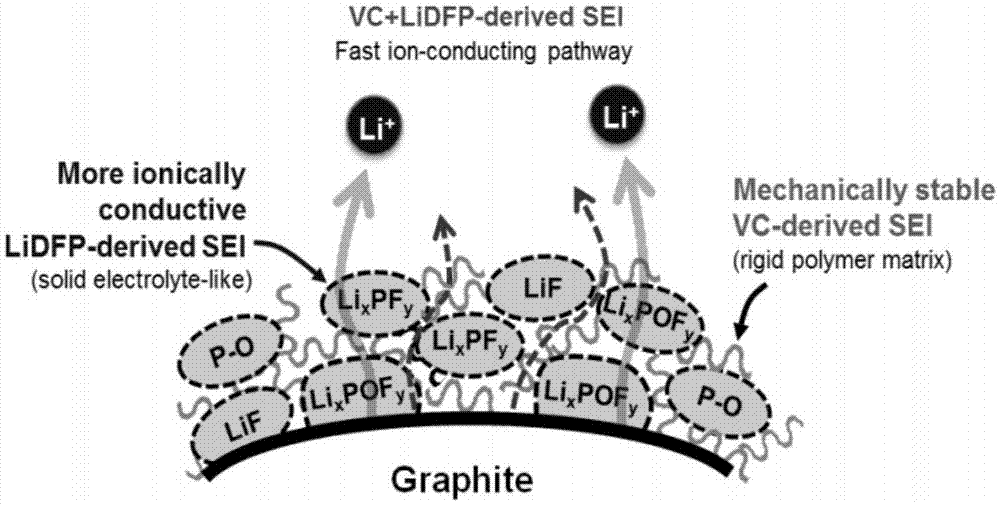

[0024] From image 3 It can be seen that the capacity retention rates of electrolyte 1 and electrolyte 2 at room temperature at 6C for 200 cycles are 96% and 88%, respectively. The addition of LiDFP additives can effectively improve the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com