Plant type instant yogurt powder and preparation method thereof

A yogurt powder, plant-based technology, applied in dairy products, milk substitutes, applications, etc., can solve the problem of no protein fermentation treatment steps, and achieve the effect of easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one: the preparation of plant type instant yoghurt powder

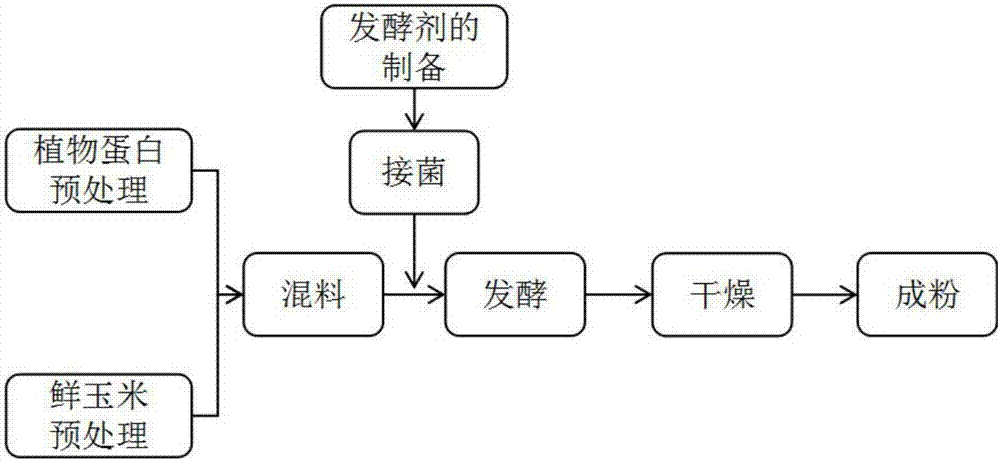

[0041] The plant-type instant yogurt powder is specifically prepared through the following technical steps, and the process flow is shown in the attached figure 1 :

[0042] (1) Preparation of starter: use inoculation loops to connect a loop of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, Bifidobacterium, and Lactobacillus plantarum in soybean protein-corn juice liquid culture medium after sterilization and cooling in CO 2 Stand and cultivate in the incubator for 24 hours respectively; strains are calculated by weight ratio, in the ratio of Streptococcus thermophilus: Lactobacillus bulgaricus: Lactobacillus acidophilus: Bifidobacterium: Lactobacillus plantarum = 49:1:10:20:20 Prepared as a leavening agent.

[0043] (2) Fresh corn pretreatment: take fresh corn as raw material, firstly clean the corn cobs without corn husk leaves and corn silk, put them in boiling...

Embodiment 2

[0050] Embodiment 2: Preparation of plant-type instant yoghurt powder

[0051] Inoculate a ring of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, Bifidobacterium, and Lactobacillus plantarum into the sterilized and cooled soybean protein-corn juice liquid medium respectively, in CO 2 The seed liquid of each single bacterium was prepared by standing in the incubator for 24 hours; the strains were calculated according to the volume ratio, and the seed liquid of each single bacterium was Streptococcus thermophilus: Lactobacillus bulgaricus: Lactobacillus acidophilus: Bifidobacterium: Lactobacillus plantarum = 49:1:10:20:20 ratio to make a starter; take fresh corn as raw material, remove corn husks and corn silks and clean them, inactivate enzymes in boiling water for 6 minutes, and then remove impurities other than corn kernels The fresh corn kernels are finely ground into a slurry through a colloid mill for 2 times, and the corn homogenate obtai...

Embodiment 3

[0052] Example 3: Preparation of Vegetable Instant Yogurt Powder

[0053] Inoculate a ring of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, Bifidobacterium, and Lactobacillus plantarum into the sterilized and cooled soybean protein-corn juice liquid medium respectively, in CO 2 The seed liquid of each single bacterium was prepared by standing in the incubator for 24 hours; the strains were calculated according to the volume ratio, and the seed liquid of each single bacterium was Streptococcus thermophilus: Lactobacillus bulgaricus: Lactobacillus acidophilus: Bifidobacterium: Lactobacillus plantarum = 49:1:10:20:20 ratio is formulated into a starter; fresh corn is used as raw material, corn husks and corn silk are removed and cleaned, enzymes are inactivated in boiling water for 8 minutes, and then impurities other than corn kernels are removed. The fresh corn kernels were finely ground into a slurry through a colloid mill for 3 times, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com