Organic waste gas plasma treatment device and method

A technology for organic waste gas and treatment equipment, which is applied in the direction of separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of low energy utilization rate, small processing capacity, and high energy consumption per unit treatment, and achieve the improvement of capacity utilization rate and increase The effect of processing capacity and improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

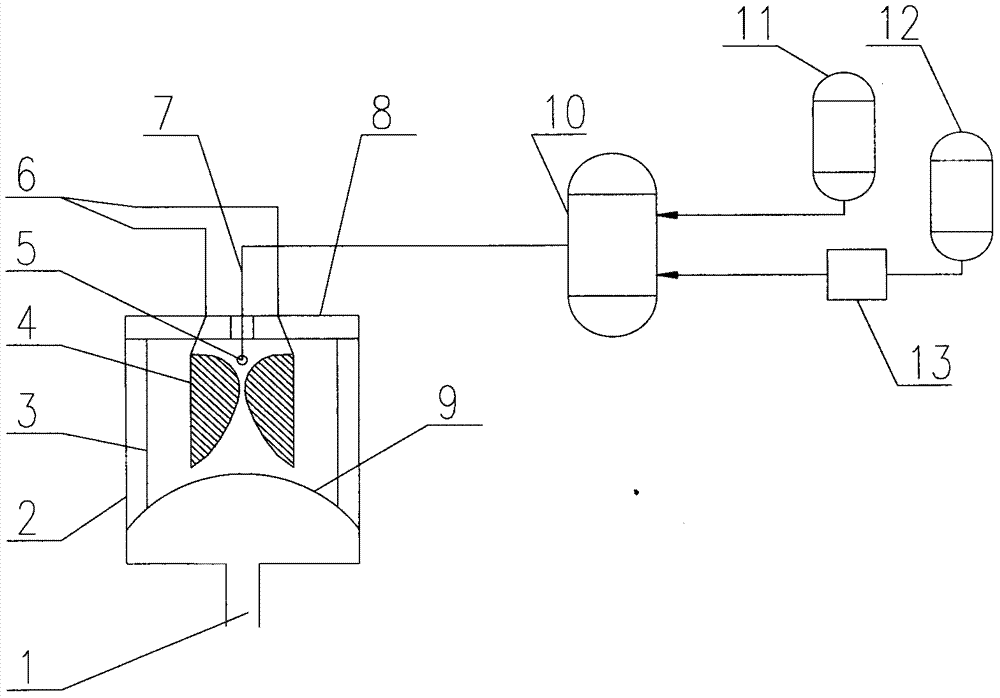

[0031] Start the high-voltage power supply, the power frequency is 25KHz, the voltage is 80KV, the fan is turned on, the content of benzene and toluene organic matter is 20000ppm, the gravure printing waste gas with a flow rate of 11112L / S and the air with a flow rate of 45L / S and a relative humidity of 2% are fed by the air intake The hole 2 enters the reactor 10, and the gas flow is ionized and broken down to form a discharge arc. The length and area of the discharge arc increase with the energy utilization plate, and the exhaust gas rises sharply from normal temperature to a high temperature of several thousand degrees. Under the dual effects of high temperature and high voltage, the industrial waste gas is in a plasma state, benzene and toluene organic substances are ionized and completely cracked, and the treated waste gas is exported through the gas outlet 1. The content of organic matter in the exhaust gas treated by the plasma equipment is 45ppm, the removal rate of o...

Embodiment 2

[0033] Start the high-voltage power supply, the frequency of the power supply is 22KHz, the voltage is 70KV, and the fan is turned on. The content of acetone, isopropanol and ammonia is 15150ppm, the flow rate is 8556L / S. The air inlet 2 enters the reactor 10, and the gas flow is ionized and broken down to form a discharge arc. The length and area of the discharge arc increase with the energy utilization plate, and the exhaust gas rises sharply from normal temperature to a high temperature of several thousand degrees. Under the dual effects of high temperature and high voltage, the industrial waste gas is in a plasma state, benzene and toluene organic substances are ionized and completely cracked, and the treated waste gas is exported through the gas outlet 1. The content of organic matter in the exhaust gas treated by the plasma equipment is 40ppm, the removal rate of organic matter is 99.7%, and the power of the plasma equipment and fan is only 38 kilowatts.

Embodiment 3

[0035] Start the high-voltage power supply, the power frequency is 10KHz, the voltage is 10KV, and the fan is turned on. The organic content of n-butane, n-pentane and other linear alkanes is 10000ppm, and the flow rate is 5530L / S. Air with a humidity of 5% enters the reactor 10 through the air inlet 2, and the air flow is ionized and broken down to form a discharge arc. The length and area of the discharge arc increase with the energy utilization plate, and the exhaust gas rises sharply from normal temperature to a high temperature of several thousand degrees. Under the dual effects of high temperature and high voltage, the industrial waste gas is in a plasma state, benzene and toluene organic substances are ionized and completely cracked, and the treated waste gas is exported through the gas outlet 1. The content of organic matter in the exhaust gas treated by the plasma equipment is 10 mg / m3, the removal rate of organic matter is 99.9%, and the power of the plasma equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com