Bismuth tungstate/carbon nitride composite photo-catalyst and preparation method and application thereof

A composite photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of large differences in the position of the valence conduction band, and achieve improved photocatalytic performance and mild reaction conditions , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

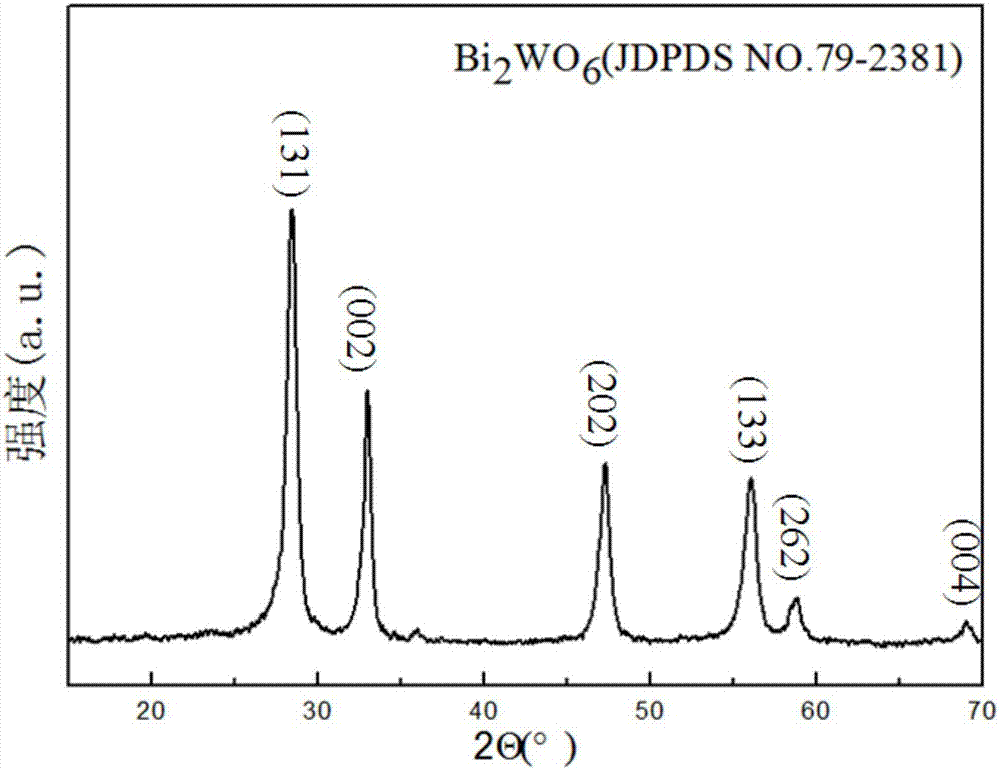

Embodiment 1

[0036] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.133mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 400W for 30min, and then at room temperature with 300rad / L Min speed magnetic stirring for 2 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W, microwave hydrothermal reaction at 180°C for 1 hour, and a white mixed solution was obtained. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 80 °C for 15 h to obtain white Bi 2 WO 6 Powder;

[0037] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1, mix them evenly and add them into deionized water to obtain a mixture, the concentration of melamine and urea in the mixture is 0.333g / mL, and stir the m...

Embodiment 2

[0040] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.14mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 500W for 20min, and then at room temperature at 350rad / L Magnetically stir for 2.5 hours at a speed of min, and finally transfer to a hydrothermal reaction kettle with a microwave power of 300W, microwave hydrothermal reaction at 190°C for 0.8 hours, and obtain a white mixed solution. The mixed solution is left to stand for stratification, and the supernatant is removed. , the precipitate was washed three times with absolute ethanol and deionized water, and dried at 70 °C for 20 h to obtain white Bi 2 WO 6 Powder;

[0041] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1.1, mix them evenly and add them into deionized water to obtain ...

Embodiment 3

[0044] Step 1: the raw material 3mmol Na 2 WO 4 and 6mmol Bi(NO 3 ) 3 Dissolve in deionized water, stir vigorously for 20min to obtain a white mixed solution, the concentration of Bi element in the mixed solution is 0.145mol / L, ultrasonically disperse the mixed solution in an ultrasonic instrument with a power of 450W for 25min, and then at room temperature with 400rad / L Magnetically stirred at a speed of min for 3 hours, and finally transferred to a hydrothermal reaction kettle with a microwave power of 300W. Microwave hydrothermal reaction was carried out at 200°C for 0.5 hours to obtain a white mixed solution. The precipitate was washed three times with absolute ethanol and deionized water, and dried at 75 °C for 18 h to obtain white Bi 2 WO 6 Powder;

[0045] Step 2: Weigh melamine and urea respectively according to the mass ratio of 1:1.2, mix them evenly and add them into deionized water to obtain a mixture, the concentration of melamine and urea in the mixture is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com