A new type of passive insulation barrel

A heat preservation barrel, a new technology, applied in the direction of heat preservation containers, packaged items, packaged food, etc., can solve the problems of large limited conditions, poor heat preservation effect of heat preservation barrels, etc., and achieve increased heat release time, good heating effect, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

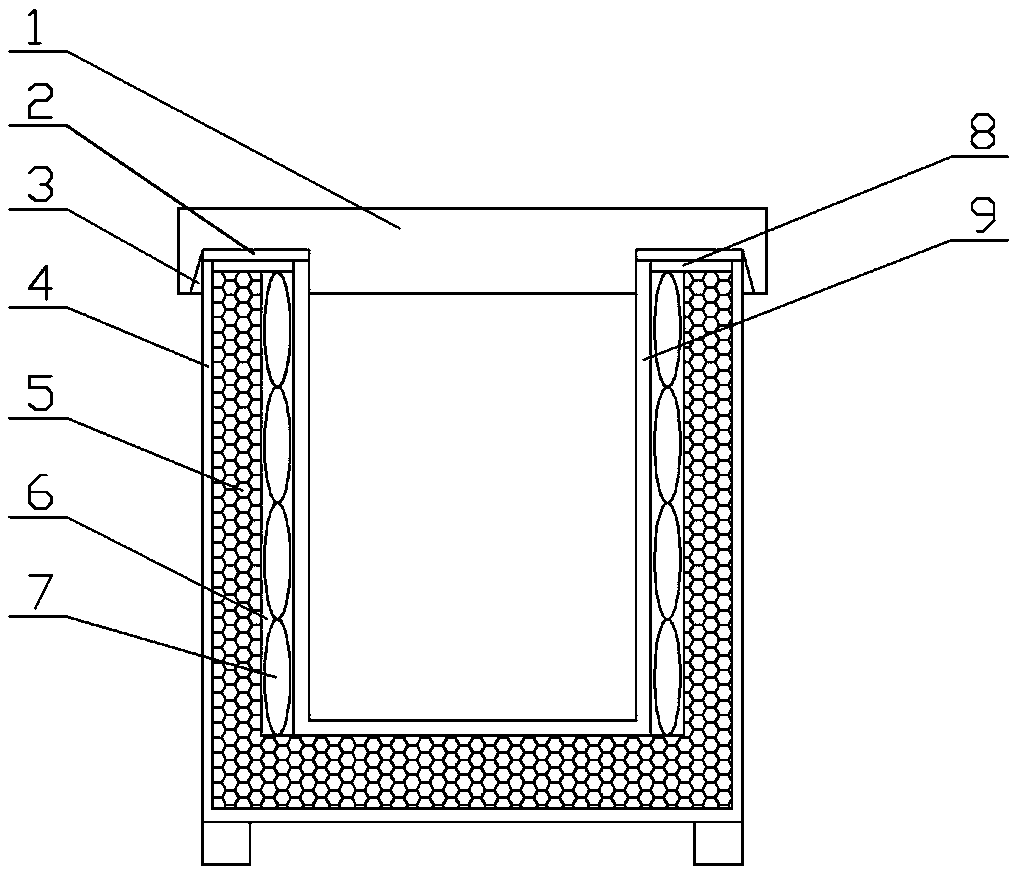

[0026] according to figure 1 , a new type of passive insulation bucket, which includes a bucket cover 1 and a cylinder body composed of an outer shell 4 and an inner lining layer 9; a heating layer 6 and a heating layer are sequentially arranged between the outer shell and the inner lining layer from inside to outside Insulation layer 5; a heating bag 7 is provided in the heating layer; a gland 8 is provided on the heating layer and the insulation layer; a groove 2 that is buckled on the barrel is provided on the bottom of the barrel cover 1; The outer ring of the groove is provided with a rubber ring 3 .

[0027] The top surfaces of the heating layer 6 and the thermal insulation layer 5 are lower than the top surfaces of the outer casing 4 and the inner lining layer 9, and are flush with the outer casing and the inner lining layer after the gland 8 is fastened.

[0028] The heating layer 6 is arranged on the circumference of the inner lining layer 9 ; the thermal insulation ...

Embodiment 2

[0035] A heating bag, the outer layer is an air-tight plastic film layer, the inner layer is a breathable non-woven fabric layer, and the inner layer is wrapped with a heating agent, and the heating agent is prepared according to the following process:

[0036] Add mullite, brucite, sepiolite and activated carbon to the crusher in sequence according to 3:2:2:1 for crushing, and then grind to obtain a powder with a particle size of 50 mesh, which is component A;

[0037] Add iron and alumina to the ball mill in turn, and grind the mixture until the particle size is 50 mesh, which is component B;

[0038] Calcinate diatomite and kaolin at 600°C for 30 minutes, and then crush them into 100-mesh powder, which is component C;

[0039] Put component A, component B, component C and water into the stirred tank reactor sequentially according to the mass ratio of 5:3:2:10, stir at 500rpm for 10min, let it stand for 60min, take it out, and prepare a particle size of 20 mesh Granules wer...

Embodiment 3

[0041] The performance test of the heating bag of the embodiment of the present invention 2:

[0042] Choose a bag length of 120mm, bag width of 100mm, and moisture permeability of 300g / m 2 .d; The weight of each bag of heating agent is 30g. Remove the outer film layer when using.

[0043] Ambient temperature: 15±2℃, humidity 40-60%.

[0044] Heating time: the time required for the sample to heat up to 60°C from the start of heating.

[0045] Maximum temperature: The highest temperature measured by the sample heating.

[0046] Duration: After the sample heats up, it starts from 40°C and returns to 40°C after the highest temperature.

[0047] Control group 1 does not add sepiolite and activated carbon, and the rest is the same as in embodiment 2; control group 2 does not add diatomite and kaolin, and the rest is the same as in embodiment 2. Three parallel groups were set up for each group, and the average value was taken. The parameters of each group are shown in Table 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com