Preparation method of double-face copper pouring ceramic substrate

A ceramic substrate and double-sided copper-clad technology, which is applied in the field of ceramic metallization, can solve the problems of unfavorable mechanical properties and surface state of the substrate, low production efficiency, and large thermal stress, so as to improve production efficiency and yield rate, and avoid product scrapping , to avoid the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step: cleaning the ceramic substrate 3, the first copper sheet 1 and the second copper sheet 2. Use acid-base solution, deionized water, ultrasonic cleaning, spraying, pre-dehydration and other processes to clean the copper sheet and ceramic sheet substrate to remove impurities on the surface of the material.

[0029] The second step: annealing the copper sheet in a nitrogen atmosphere with an oxygen content of 1000 ppm, setting a temperature of 800°C, and an annealing treatment time of 15 minutes, to produce a certain thickness of oxide layer on the surface.

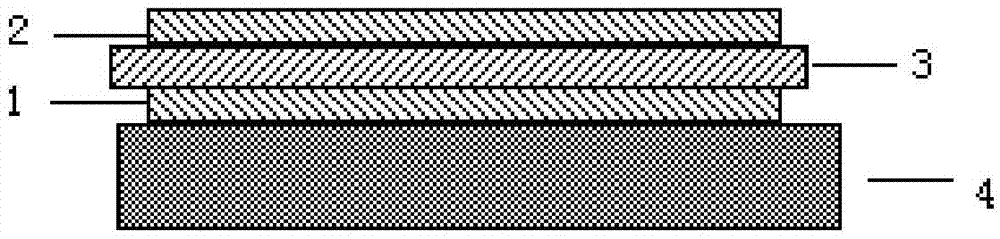

[0030] The third step: In a nitrogen atmosphere with an oxygen content of 40 ppm, stack the gasket 4 in the order of the first copper sheet 1, the ceramic substrate 3, and the second copper sheet 2 (the material of the gasket 4 is Inconel718, thickness 3mm, roughness 5μm) (the first copper piece 1 is placed on the gasket 4, the ceramic piece 3 is placed on the surface of the first copper piece 1, and the sec...

Embodiment 2

[0034] The first step: cleaning the ceramic substrate 3, the first copper sheet 1 and the second copper sheet 2. Use acid-base solution, deionized water, ultrasonic cleaning, spraying, pre-dehydration and other processes to clean the copper sheet and ceramic sheet substrate to remove impurities on the surface of the material.

[0035] The second step: annealing the copper sheet in a nitrogen atmosphere with an oxygen content of 950 ppm, setting a temperature of 900°C, and an annealing treatment time of 15 minutes to produce a certain thickness of oxide layer on the surface.

[0036] The third step: under a nitrogen atmosphere with an oxygen content of 30 ppm, stack the gasket 4 (material Y of gasket 4) in the order of the first copper sheet 1, the ceramic substrate 3, and the second copper sheet 2 2 O 3 , Thickness 2mm, roughness 4μm) (the first copper piece 1 is placed on the gasket 4, the ceramic piece 3 is placed on the surface of the first copper piece 1, and the second copper p...

Embodiment 3

[0040] The first step: cleaning the ceramic substrate 3, the first copper sheet 1 and the second copper sheet 2. Use acid-base solution, deionized water, ultrasonic cleaning, spraying, pre-dehydration and other processes to clean the copper sheet and ceramic sheet substrate to remove impurities on the surface of the material.

[0041] The second step: annealing the copper sheet in a nitrogen atmosphere with an oxygen content of 1100 ppm, setting a temperature of 780°C, and an annealing treatment time of 15 minutes to produce a certain thickness of oxide layer on the surface.

[0042] The third step: In a nitrogen atmosphere with an oxygen content of 35ppm, stack the gasket 4 (the material of the gasket 4 is nickel-cadmium alloy) in the order of the first copper sheet 1, the ceramic substrate 3, and the second copper sheet 2 , Thickness 1mm, roughness 3μm) (the first copper piece 1 is placed on the gasket 4, the ceramic piece 3 is placed on the surface of the first copper piece 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com