High-temperature-resistant print label and preparation method thereof

A technology of high temperature resistance and labeling, which is applied in the field of polymer materials, can solve problems such as low temperature resistance, label deformation, and product scrapping, and achieve good heat dissipation, strong adhesion, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a high temperature resistant printing label, comprising the following steps:

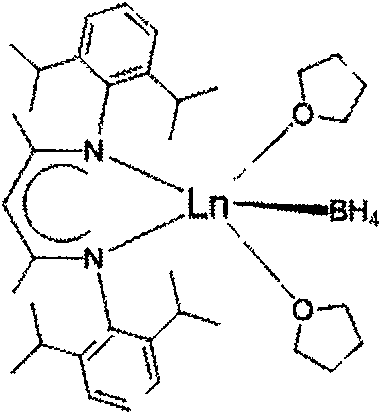

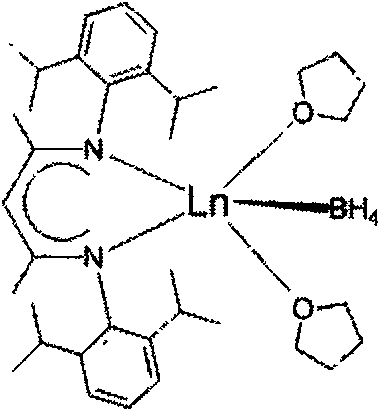

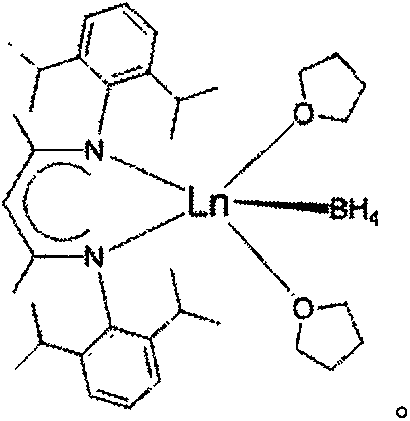

[0021] (1) Mix zinc acetate aqueous solution and aluminum chloride aqueous solution; after stirring for 0.5 hours, add isomeric tridecanol polyoxyethylene ether, stir at 50°C for 0.3 hours; then add lithium bromide, and stir for 0.2 hours; then add rare earth borohydride complex and Lauryl methacrylate, stirred at 80°C for 3 hours; then filtered, the filter cake was treated according to the process of 120°C / 10 minutes + 350°C / 20 minutes + 880°C / 30 minutes + 960°C / 10 minutes, cooled naturally, and finally crushed Obtain powder; then powder, ethylene glycol dimethacrylate, N-vinylpyrrolidone, ethanol were mixed, stirred for 5 minutes, then added hydroxyl-terminated polysiloxane, polymethyl methacrylate microspheres, 50 Stir at ℃ for 2 hours; finally dry to obtain the filler; the molecular weight of the hydroxyl-terminated polysiloxane is 2600-3000; the molecular structure...

Embodiment 2

[0028] A product with a high-temperature-resistant printing label. The label in Example 1 is hot-air pasted on the ceramic pre-processed part, and the barcode is directly printed on the surface of the high-temperature-resistant coating; when the ceramic part is processed at a high temperature of 400 ° C, the label can still be maintained. Good integrity, barcode information is relatively clear, easy to trace product information.

Embodiment 3

[0030] A product with a high-temperature-resistant printing label. The label in Example 1 is pasted on the circuit board with hot air, and the barcode is directly printed on the surface of the high-temperature-resistant coating; when the circuit board is returned to the furnace for 360°C high-temperature processing, the label can still be maintained. The integrity of the barcode information is relatively clear, which is convenient for the display of product information.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com