Anti-radiation coating and preparation method thereof

A technology of anti-radiation coatings, pigments and fillers, applied in the field of anti-radiation coatings, can solve the problems of poor adhesion, secondary pollution, poor corrosion resistance, etc., and achieve the effects of excellent radiation resistance, increased concentration and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

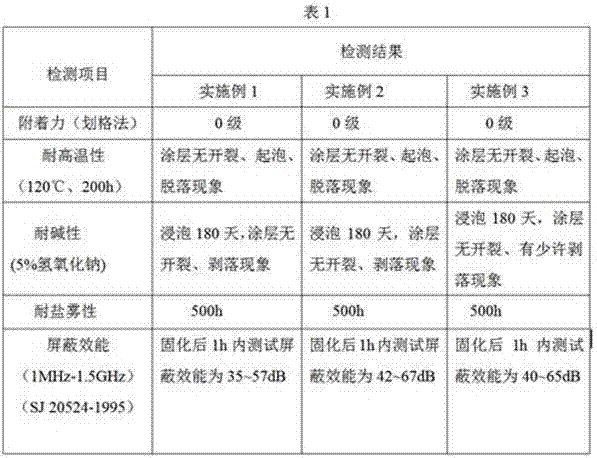

Examples

Embodiment 1

[0027] An anti-radiation coating, the content of each component in the coating is as follows: 35% of acrylic emulsion, 0.5% of graphene, 0.2% of nano-silver, 20% of dispersant, 0.6% of alcohol ester-12, hydroxypropyl methylcellulose 1%, pigment and filler 4%, defoamer 0.1%, deionized water balance.

[0028] The mass percent of each component in the above-mentioned dispersant in the paint is: chitosan 10%, polyvinyl alcohol 5%, sodium dodecylsulfonate 5%. The mass percentages of the components in the above-mentioned pigments and fillers in the paint are: 2% titanium dioxide, 1% glass powder, and 1% talcum powder.

[0029] Above-mentioned a kind of anti-radiation coating, preparation method comprises the following steps:

[0030] (1) According to the composition of the raw material, mix the graphene powder with the dispersant, put it in a sand mill for grinding for 2 hours, then transfer it to an ultrasonic disperser, and disperse it at a speed of 1200r / min for 4 hours to obtai...

Embodiment 2

[0034] An anti-radiation coating, the content of each component in the coating is as follows: 40% of acrylic emulsion, 0.8% of graphene, 0.5% of nano-silver, 25% of dispersant, 0.8% of alcohol ester-12, hydroxypropyl methylcellulose 0.5%, pigments and fillers 3%, defoamer 0.2%, the balance of deionized water.

[0035] The mass percent of each component in the above-mentioned dispersant in the paint is: chitosan 10%, polyvinyl alcohol 8%, sodium dodecylsulfonate 7%. The mass percentages of the components in the above-mentioned pigments and fillers in the paint are: 1.5% titanium dioxide, 1% glass powder, and 0.5% talcum powder.

[0036] The preparation method of the above-mentioned anti-radiation coating is the same as in Example 1.

Embodiment 3

[0038] An anti-radiation coating, the content of each component in the coating is as follows: 30% of acrylic emulsion, 1.5% of graphene, 0.1% of nano-silver, 15% of dispersant, 0.6% of alcohol ester-12, hydroxypropyl methylcellulose 0.5%, pigments and fillers 5%, defoamer 0.2%, deionized water balance.

[0039] The mass percent of each component in the above-mentioned dispersant in the paint is: chitosan 10%, polyvinyl alcohol 3%, sodium dodecylsulfonate 2%. The mass percentages of the components in the above-mentioned pigments and fillers in the paint are: 2% titanium dioxide, 2% glass powder, and 1% talcum powder.

[0040] The preparation method of the above-mentioned anti-radiation coating is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com