Method of purifying yeast wastewater by co-culture of chlorella and yeast

A technology of yeast wastewater and chlorella, applied in the field of cell culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

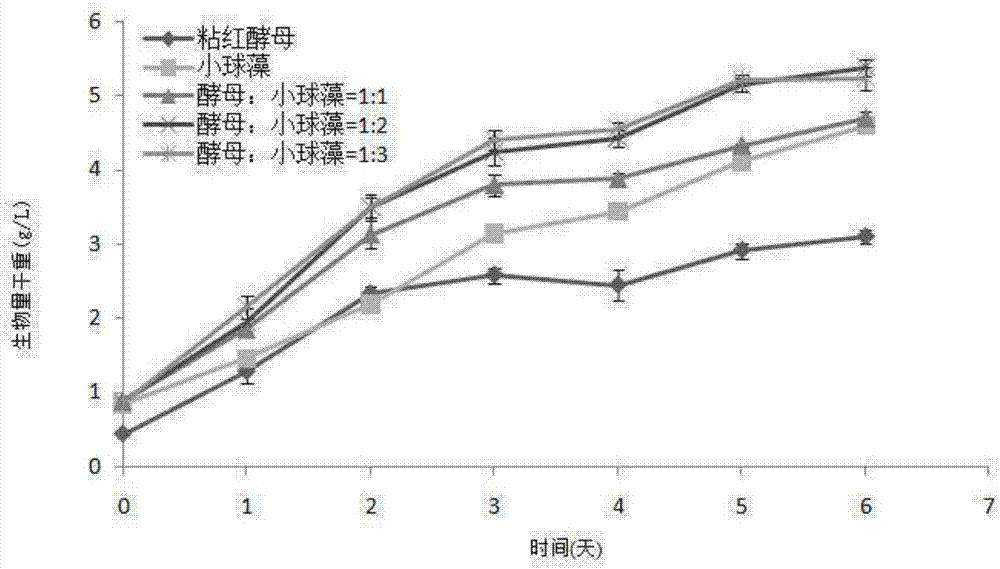

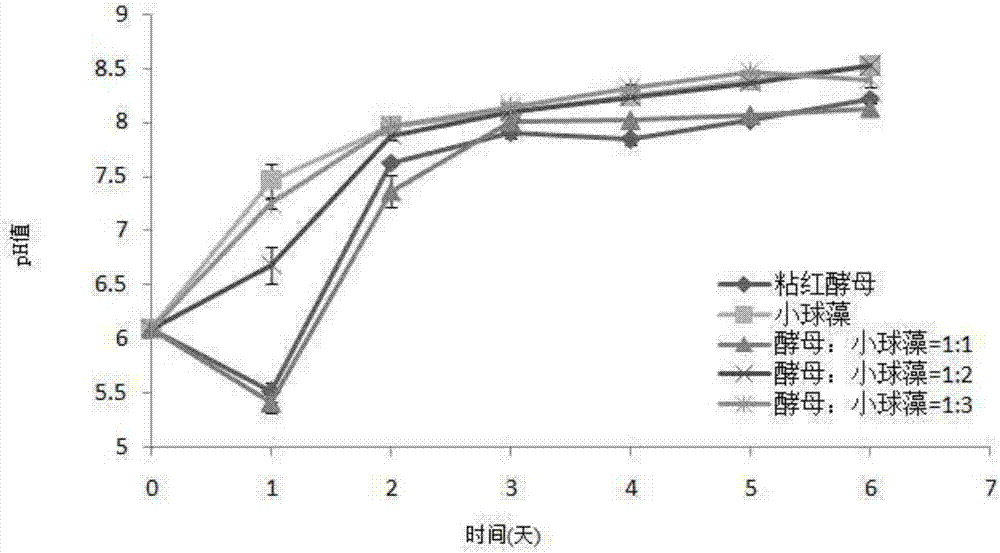

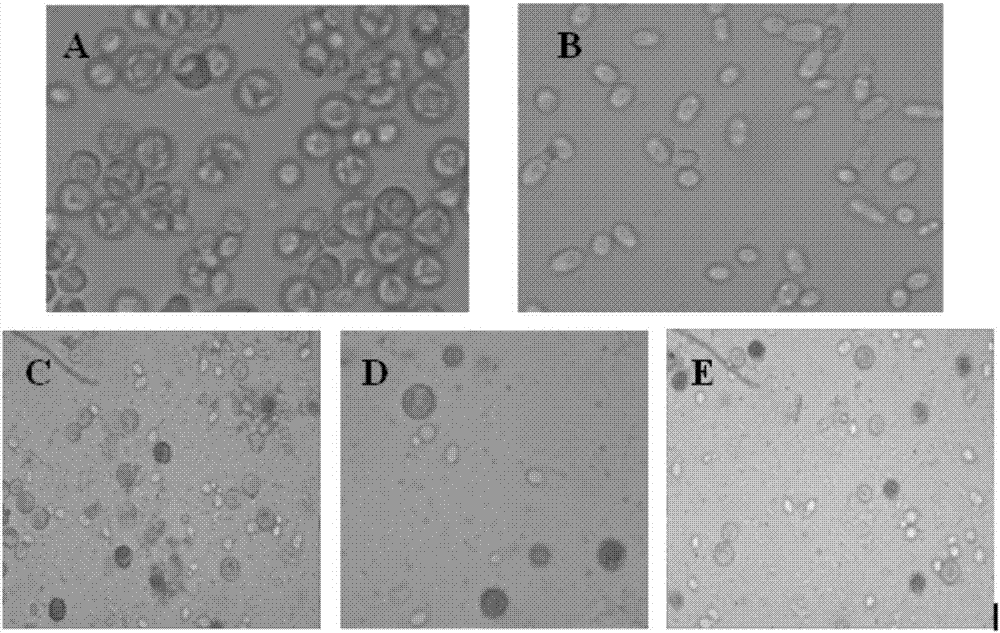

[0058] Embodiment 1: investigate the inoculation ratio of Chlorella pyrenoidosa and Rhodotorula viscosus

[0059] Experimental steps:

[0060] 1) Inoculate the cells of Chlorella pyrenoidosa and Rhodotorula viscosus into 250ml Erlenmeyer flasks equipped with improved basal medium and YM medium respectively, and place them in a constant temperature shaker at 28°C, 150r / m, and a light intensity of 4000lux , continuously cultivated for 6 days to obtain Chlorella pyrenoidosa seed liquid I and Rhodotorula viscosus seed liquid I.

[0061] Improved basal medium: NaNO 3 3750mg / L, KH 2 PO 4 1250mg / L, MgSO 4 ·7H 2 O 1000mg / L, EDTA500mg / L, H 3 BO 3 114.2mg / L, CaCl 2 2H 2 O 111mg / L, FeSO 4 ·7H 2 O49.8mg / L, ZnSO 4 ·7H 2 O88.2mg / L, MnCl 2 4H 2 O 14.2mg / L, Na2 M0O 4 2H 2 O 11.92mg / L, CuSO 4 ·5H 2 O 15.7mg / L, Co(NO 3 ) 2 ·6H 2 O 4.9mg / L, C 6 h 12 o 6 50g / L. Adjust the pH to 6.10.

[0062] YM medium: casein peptone 5.0g / L, malt extract powder 3.0g / L, glucose 10.0g / L,...

Embodiment 2

[0071] Embodiment 2: Step 3) Adopt preferred scheme one, Chlorella pyrenoidosa and Rhodotorula viscosus co-cultivate and process yeast wastewater in an outdoor 700L pipeline photobioreactor

[0072] Experimental steps:

[0073] 1) Inoculate the cells of Chlorella pyrenoidosa and Rhodotorula viscosus into 250ml Erlenmeyer flasks equipped with improved basal medium and YM medium respectively, and place them in a constant temperature shaker at 28°C, 150r / m, and a light intensity of 4000lux , continuously cultivated for 6 days to obtain Chlorella pyrenoidosa seed liquid I and Rhodotorula viscosus seed liquid I.

[0074] Improved basal medium: NaNO 3 3750mg / L, KH 2 PO 4 1250mg / L, MgSO 4 ·7H 2 O 1000mg / L, EDTA500mg / L, H 3 BO 3 114.2mg / L, CaCl 2 2H 2 O 111mg / L, FeSO 4 ·7H 2 O 49.8mg / L, ZnSO 4 ·7H 2 O88.2mg / L, MnCl 2 4H 2 O 14.2mg / L, Na 2 MoO 4 2H 2 O 11.92mg / L, CuSO 4 ·5H 2 O 15.7mg / L, Co(NO 3 ) 2 ·6H 2 O 4.9mg / L, C 6 h 12 o 6 50g / L. Adjust the pH to 6.10. ...

Embodiment 3

[0083] Embodiment 3: Step 3) Adopt preferred scheme two, Chlorella pyrenoidosa and Rhodotorula viscosus co-cultivate and process yeast wastewater in an outdoor 1300L pipeline photobioreactor

[0084] Experimental steps:

[0085] 1) Inoculate the cells of Chlorella pyrenoidosa and Rhodotorula viscosus into 250ml Erlenmeyer flasks equipped with improved basal medium and YM medium respectively, and place them in a constant temperature shaker at 28°C, 150r / m, and a light intensity of 4000lux , continuously cultivated for 6 days to obtain Chlorella pyrenoidosa seed liquid I and Rhodotorula viscosus seed liquid I.

[0086] Improved basal medium: NaNO 3 3750mg / L, KH 2 PO 4 1250mg / L, MgSO 4 ·7H 2 O 1000mg / L, EDTA500mg / L, H 3 BO 3 114.2mg / L, CaCl 2 2H 2 O 111mg / L, FeSO 4 ·7H 2 O 49.8mg / L, ZnSO 4 ·7H 2 O88.2mg / L, MnCl 2 4H 2 O 14.2mg / L, Na 2 MoO 42H 2 O 11.92mg / L, CuSO 4 ·5H 2 O 15.7mg / L, Co(NO 3 ) 2 ·6H 2 O 4.9mg / L, C 6 h 12 o 6 50g / L. Adjust the pH to 6.10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com