High-speed visual positioning and correction system of solar cell piece and method of high-speed visual positioning and correction system

A technology of solar cells and visual positioning, which is applied in the field of visual inspection, can solve the problems of increasing the probability of workpiece damage, slow speed, and inability to adapt to the production line, so as to improve production efficiency, improve the precision of string welding, and improve the degree of flexibility and automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with specific embodiment:

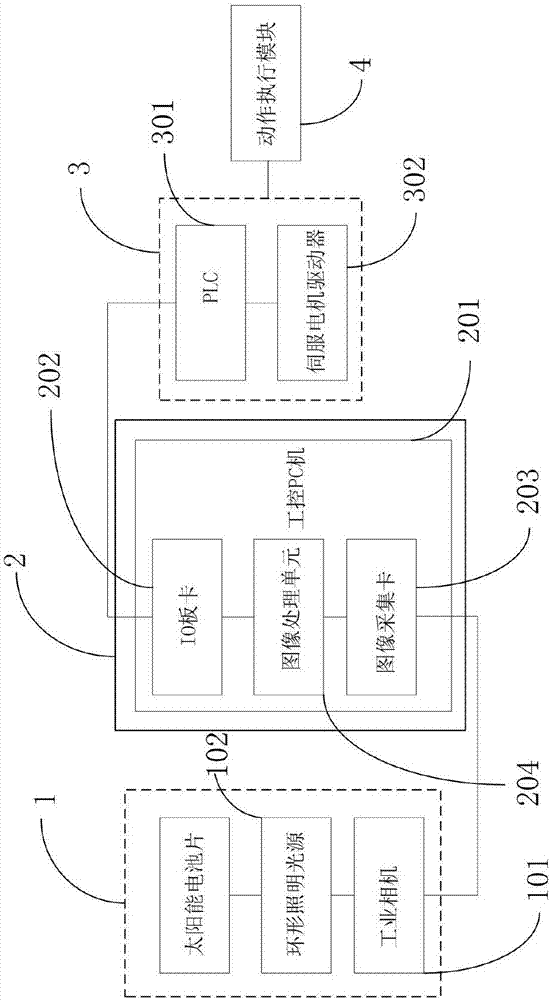

[0060] See attached figure 1 As shown, a solar cell high-speed visual positioning and correction system described in this embodiment includes an image acquisition module 1, an image processing module 2, a motion control module 3 and an action execution module 4, and the four are sequentially connected;

[0061] The image acquisition module 1 includes an industrial camera 101 and a ring-shaped light source 102; wherein the ring-shaped light source 102 is positioned between the solar cells in a good position and the industrial camera 101, and the industrial camera 101 is positioned directly below the ring-shaped light source 102 and shoots vertically upwards For solar cells, it is necessary to adjust the focal length, exposure time and strobe of the industrial 101 camera before shooting; this module is used to automatically collect images of solar cells on the automatic produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com