Plastic plate or film having super steel wool resistance and weathering resistance, and preparation method thereof

A super-resistant steel and plastic plate technology, applied in the field of plate processing, can solve the problems of poor system compatibility, poor stability, performance and appearance damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

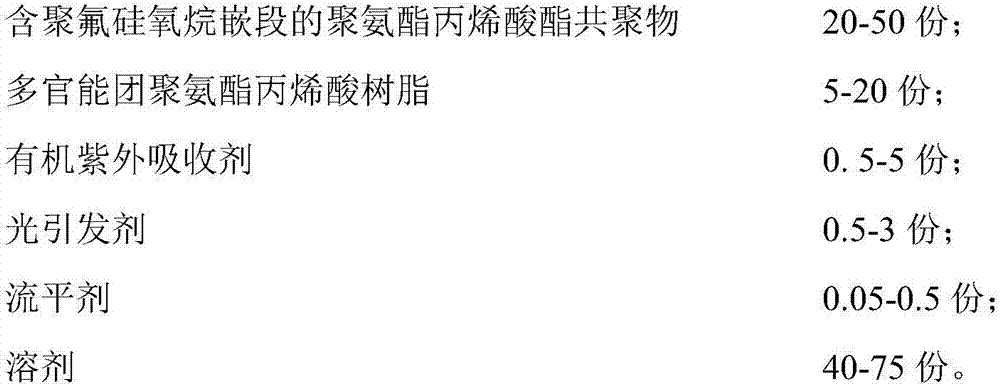

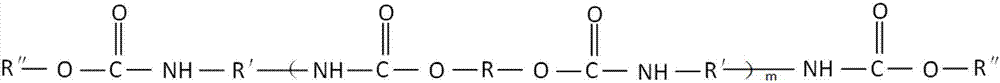

[0113] A plastic plate with super steel wool resistance and weather resistance at the same time, comprising a substrate, a first film layer with weather resistance on the surface of the substrate, and a second layer on the surface of the first film layer with weather resistance At the same time, it has a super-steel wool-resistant and weather-resistant film layer, and the second layer has both a super-steel wool-resistant and a weather-resistant film layer. Clothed on the surface of the first layer of weather-resistant film layer and cured by ultraviolet light irradiation; the first layer of weather-resistant film layer is obtained by spraying the weather-resistant coating on both sides Coated on the surface of the substrate, obtained by low-temperature flash-drying coating;

[0114] The substrate is Sabic's 12.0mmPC and PMMA composite sheet;

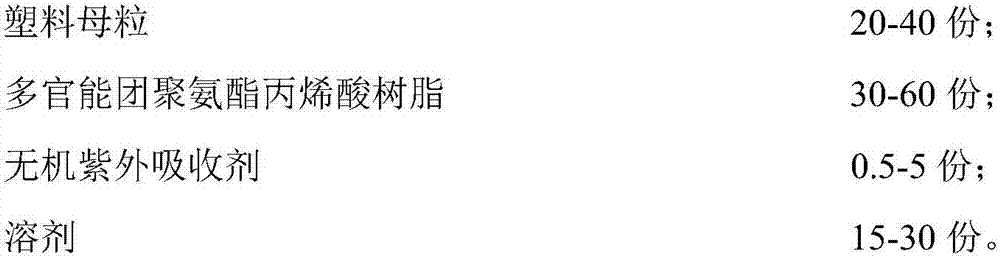

[0115] The coating with weather resistance in the first layer of weather resistance film layer includes:

[0116] 35 parts by weight...

Embodiment 2

[0145] A plastic plate with super steel wool resistance and weather resistance at the same time, comprising a substrate, a first film layer with weather resistance on the surface of the substrate, and a second layer on the surface of the first film layer with weather resistance At the same time, it has a super-steel wool-resistant and weather-resistant film layer, and the second layer has both a super-steel wool-resistant and a weather-resistant film layer. It is coated on the surface of the first layer of weather-resistant film layer and cured after being irradiated with ultraviolet light; the first layer of weather-resistant film layer is obtained by applying a coating with weather-resistant property through flow coating Double-sided coating on the surface of the substrate, obtained by low-temperature flash-drying coating;

[0146] The base material is the 3.0mm PC board of Sabic;

[0147] The coating with weather resistance in the first layer of weather resistance film lay...

Embodiment 3

[0177] A plastic plate with super steel wool resistance and weather resistance at the same time, comprising a substrate, a first film layer with weather resistance on the surface of the substrate, and a second layer on the surface of the first film layer with weather resistance At the same time, it has a super-steel wool-resistant and weather-resistant film layer, and the second layer has both a super-steel wool-resistant and a weather-resistant film layer. It is coated on the surface of the first layer of weather-resistant film layer and cured after being irradiated with ultraviolet light; the first layer of weather-resistant film layer is obtained by applying a coating with weather-resistant property through flow coating Double-sided coating on the surface of the substrate, obtained by low-temperature flash-drying coating;

[0178] The substrate is a 188 μm PET film from Toray, Japan;

[0179] The coating with weather resistance in the first layer of weather resistance film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com