A carbon quantum dot/attapulgite nanocomposite material and its preparation method and application

A nanocomposite material and carbon quantum dot technology, which is applied in the field of carbon quantum dot/attapulgite nanocomposite material and its preparation, can solve the problems of expensive hydrogen, high temperature and high pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.32g, 0.9mol L of citric acid -1 Add 1mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 160°C for 8h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C drying, and then grinding to obtain the CQDs / ATP nanocomposite material.

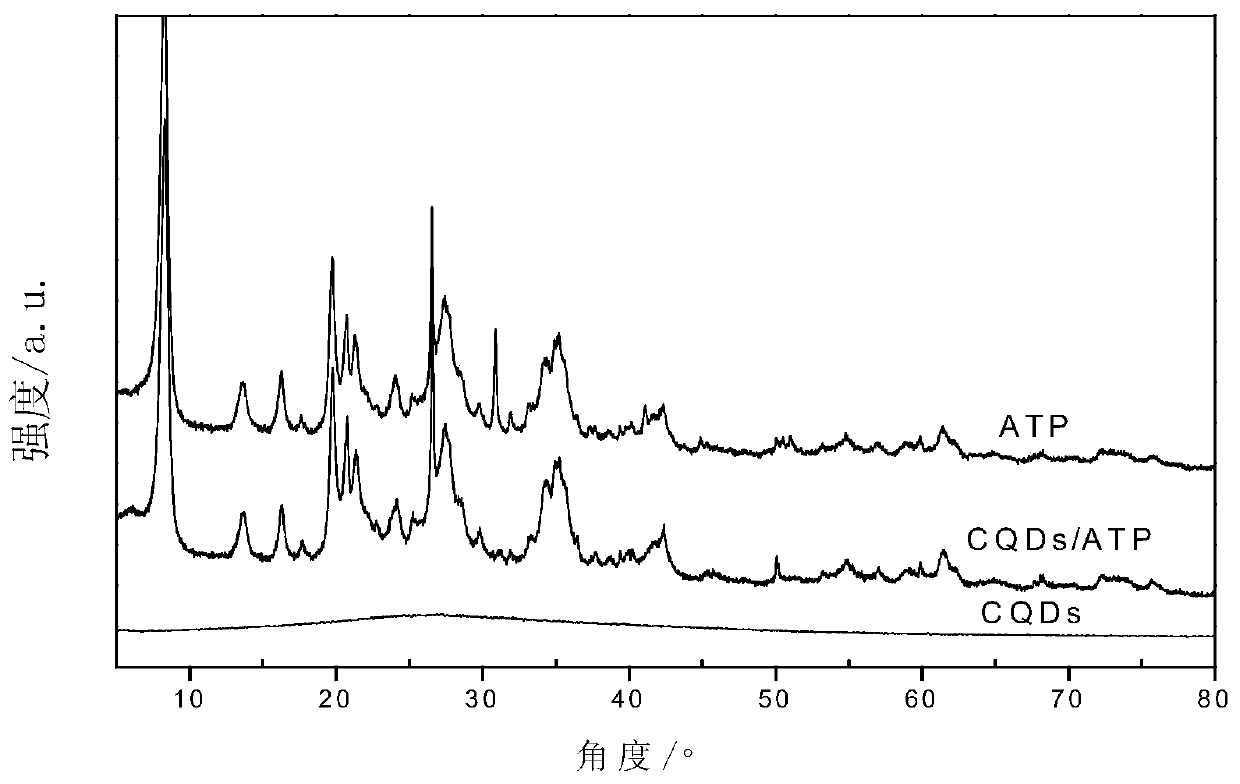

[0017] X-ray powder diffraction was performed on the obtained CQDs / ATP nanocomposites, as figure 1 As shown, the characteristic peaks of carbon quantum dots and attapulgite appeared in the XRD of the composite material, indicating that carbon quantum dots and attapulgite were successfully composited;

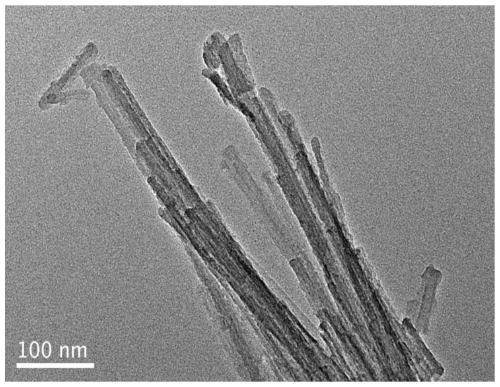

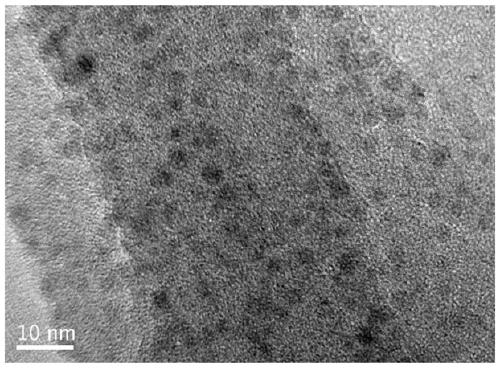

[0018] The morphology of CQDs / ATP nanocomposites was observed by transmission electron microscopy: TEM images of ATP are shown in figure 2 As shown, the attapulgite presents a nanorod-like structure; the TEM image of the obtained CQDs / ATP in this example is shown in image 3 ...

Embodiment 2

[0028] Weigh 0.12g, 0.9mol L of citric acid -1 Add 0.375mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 120°C for 24h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C The CQDs / ATP nanocomposite can be obtained after drying in medium temperature and then grinding. Subsequent detection was as in Example 1.

Embodiment 3

[0030] Weigh 0.21g, 0.9mol L of citric acid -1 Add 0.66mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 140°C for 20h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C The CQDs / ATP nanocomposite can be obtained after drying in medium temperature and then grinding. Subsequent detection was as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com