Preparation method of sodium p-styrene sulfonate

A technology of sodium styrene sulfonate and bromophenylethane sulfonic acid is applied in the field of preparation of sodium p-styrene sulfonate, can solve the problems of high impurity content in the product, restricting the scope of use and product performance, etc., and achieves short reaction time, Sulfonation has good para-position and the effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

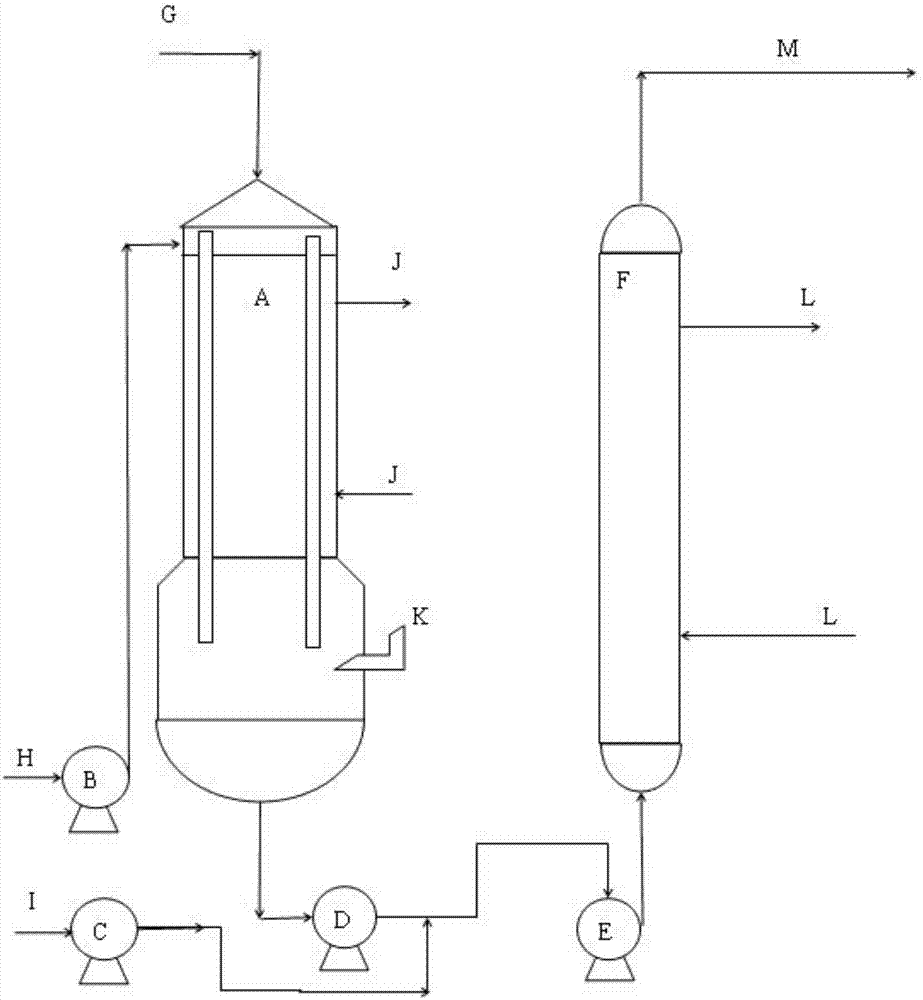

Method used

Image

Examples

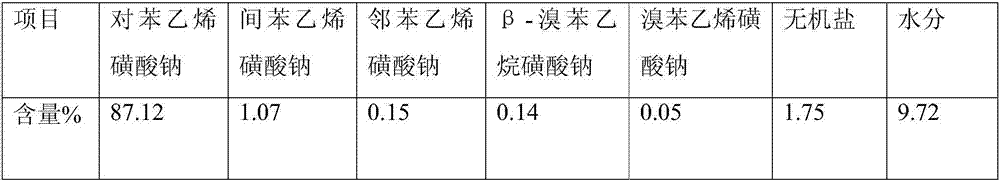

Embodiment 1

[0038] The bromophenylethane is quantitatively and continuously delivered to the head of the composite sulfonation reactor at a rate of 25 kg per hour by the bromophenylethane metering pump, and according to the molar ratio of 1:1.05, continuously and uniformly feed the trioxide with a mass content of 8% sulfur trioxide. Sulfur / air 142kg / hour, continuous sulfonation reaction occurs in the vertical tubular reactor in the composite sulfonation reactor, the temperature is controlled at 85°C, after preliminary sulfonation, it enters the aging homogeneous separation tank, and the tail gas is emptied after treatment Obtain 35.7kg of bromophenylethane sulfonic acid per hour, after testing: 0.2% of unsulfonated substance, 0.25% of sulfuric acid content; Uniformly add sodium hydroxide mass content 48% liquid caustic soda 23.65kg / hour, material neutralization temperature control 45-55 ℃, quickly heat up to 110 ℃ through heat exchanger to remove bromine, obtain liquid sodium p-styrene sul...

Embodiment 2

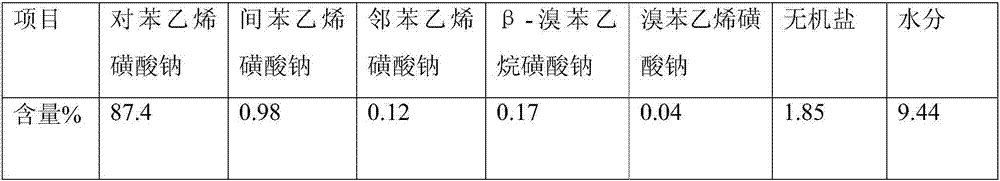

[0043] The bromophenylethane is quantitatively and continuously delivered to the head of the compound sulfonation reactor at a rate of 25 kg per hour by the bromophenylethane metering pump, and according to the molar ratio of 1:1.08, continuously and uniformly feed the trioxide with a mass content of 10% sulfur trioxide. Sulfur / air 116.7kg / hour, continuous sulfonation reaction occurs in the vertical tubular reactor in the composite sulfonation reactor, the temperature is controlled at 95°C, after preliminary sulfonation, it enters the aging homogeneous separation tank, and the tail gas is discharged after treatment Empty; obtain bromophenylethane sulfonic acid 35.8kg / hour, after testing: non-sulfonated matter 0.22%, sulfuric acid content 0.27%; Continuously and evenly add 23.65kg / hour of liquid caustic soda with a mass content of 48% of sodium hydroxide, control the neutralization temperature of the material at 45-55°C, and quickly raise the temperature to 110°C through a heat...

Embodiment 3

[0048]The bromophenylethane is quantitatively and continuously delivered to the head of the composite sulfonation reactor by the bromophenylethane metering pump at a rate of 25 kg per hour, and according to the molar ratio of 1:1.1, the trioxide with a mass content of sulfur trioxide of 10% is continuously and uniformly fed. Sulfur / air 118.9kg / hour, continuous sulfonation reaction occurs in the vertical tubular reactor in the composite sulfonation reactor, the temperature is controlled at 105°C, after preliminary sulfonation, it enters the aging homogeneous separation tank, and the tail gas is discharged after treatment Empty; obtain bromophenylethanesulfonic acid 35.9kg / hour, after testing: non-sulfonated substance 0.17%, sulfuric acid content 0.29%; Continuously and evenly add 23.65kg / hour of liquid caustic soda with a mass content of 48% of sodium hydroxide, control the neutralization temperature of the material at 45-55°C, and quickly raise the temperature to 110°C through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com