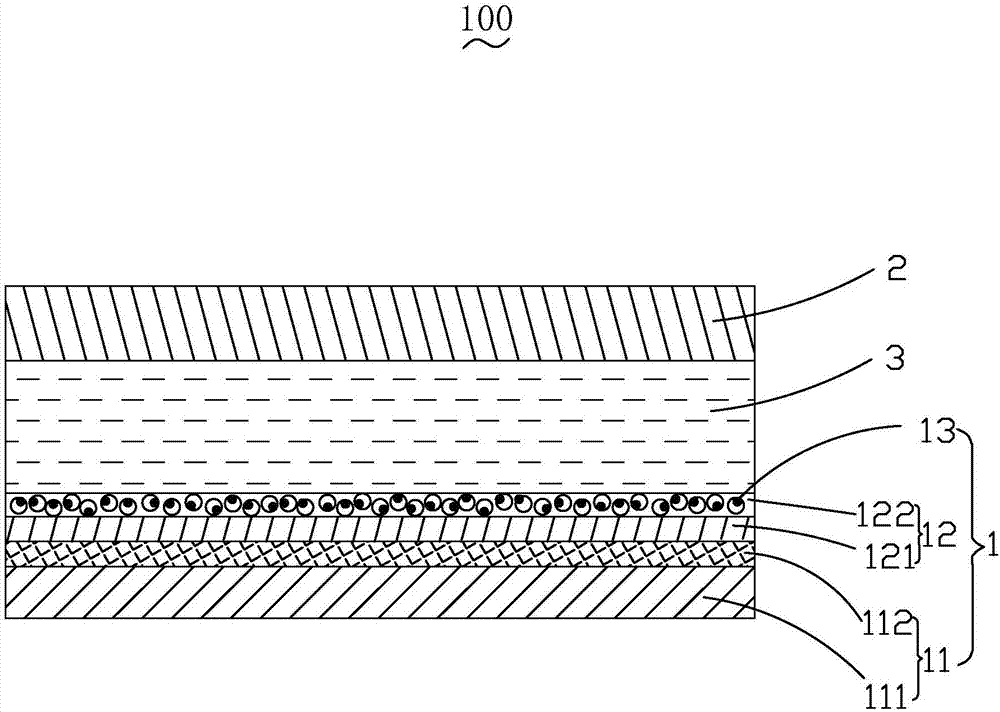

Composite thin film dye-sensitized solar cell and manufacturing method therefor

A technology for solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of affecting energy conversion efficiency, failing to effectively improve open circuit voltage, affecting the increase of short-circuit photocurrent, etc., so as to improve photoelectric conversion efficiency, reduce losses, improve collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

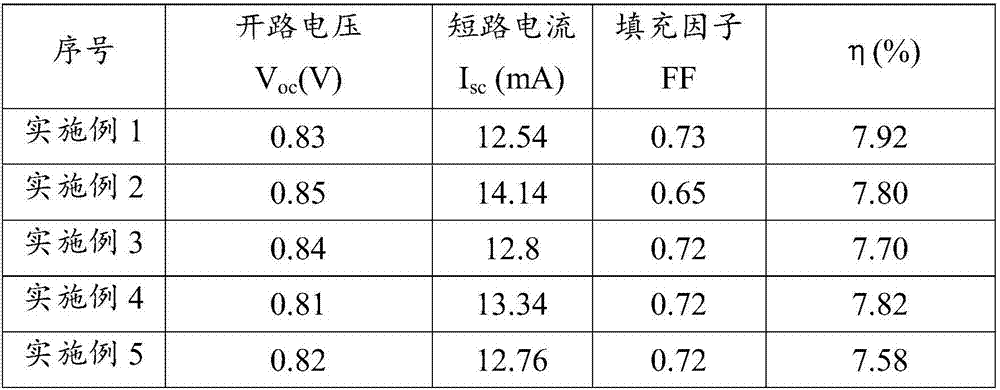

Embodiment 1

[0054] A method for making a composite thin film dye-sensitized solar cell, comprising the steps of:

[0055] Step S1: forming and preparing the Ba(Ti 0.9 sn 0.1 )O 3 film layer 121;

[0056] Specifically, the following steps are included:

[0057] Step S11: Prepare Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0058] Specifically, BaCO 3 、TiO 2 and SnO 2 As the raw material, weigh the raw material according to the stoichiometric ratio and put it into a ball mill, add an appropriate amount of absolute ethanol, and ball mill for 12 hours; the slurry after ball milling is filtered and dried, and put into a graphite mold and sintered in a sintering furnace, the sintering temperature at 1000°C, Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0059] Step S12: Ba(Ti 0.9 sn 0.1 )O 3 Thoroughly grind in absolute ethanol, and filter the grinding slurry;

[0060] Step S13: Add 0.5wt% PEG200 to the filtered slurry, grind it thoroughly, and ultrasonically disperse it for later use;

[0061...

Embodiment 2

[0074] A method for making a composite thin film dye-sensitized solar cell, comprising the steps of:

[0075] Step S1: forming and preparing the Ba(Ti 0.9 sn 0.1 )O 3 film layer 121;

[0076] Specifically, the following steps are included:

[0077] Step S11: Prepare Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0078] Specifically, BaCO 3 、TiO 2 and SnO 2 As the raw material, weigh the raw material according to the stoichiometric ratio and put it into a ball mill, add an appropriate amount of absolute ethanol, and ball mill for 12 hours; the slurry after ball milling is filtered and dried, and put into a graphite mold and sintered in a sintering furnace, the sintering temperature is 1050°C, and Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0079] Step S12: Ba(Ti 0.9 sn 0.1 )O 3 Thoroughly grind in absolute ethanol, and filter the grinding slurry;

[0080] Step S13: Add 0.5wt% PEG200 to the filtered slurry, grind it thoroughly, and ultrasonically disperse it for later use;

[...

Embodiment 3

[0094] A method for making a composite thin film dye-sensitized solar cell, comprising the steps of:

[0095] Step S1: forming and preparing the Ba(Ti 0.9 sn 0.1 )O 3 film layer 121;

[0096] Specifically, the following steps are included:

[0097] Step S11: Prepare Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0098] Specifically, BaCO 3 、TiO 2 and SnO 2 As the raw material, weigh the raw material according to the stoichiometric ratio and put it into a ball mill, add an appropriate amount of absolute ethanol, and ball mill for 12 hours; the slurry after ball milling is filtered and dried, and put into a graphite mold and sintered in a sintering furnace, the sintering temperature is 1100°C, and Ba(Ti 0.9 sn 0.1 )O 3 Nano powder;

[0099] Step S12: Ba(Ti 0.9 sn 0.1 )O 3 Thoroughly grind in absolute ethanol, and filter the grinding slurry;

[0100] Step S13: Add 0.5wt% PEG200 to the filtered slurry, grind it thoroughly, and ultrasonically disperse it for later use;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com