Epitaxial structure of ultraviolet light emitting diode and preparation method thereof

A technology of light-emitting diodes and epitaxial structures, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult material preparation, increased mobility, and low yield of ultraviolet LEDs, and achieves improved light output power and luminous efficiency. The effect of reducing dislocation density and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

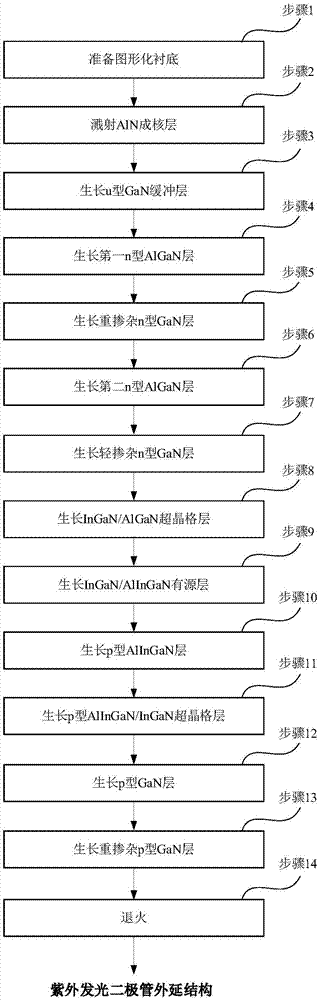

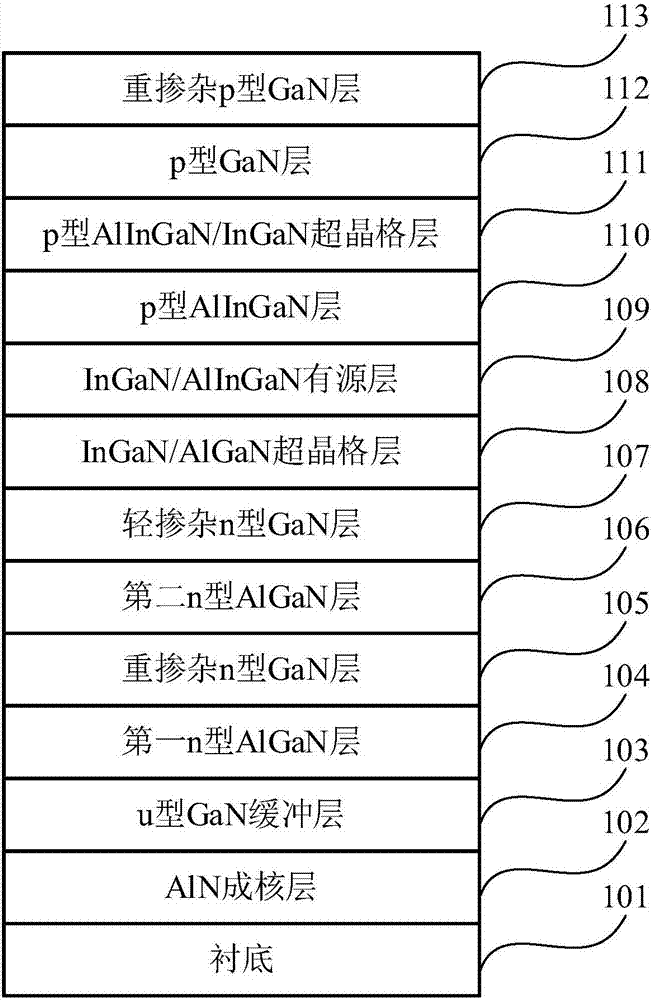

[0026] Such as figure 1 As shown, the method for preparing the epitaxial structure of the ultraviolet light emitting diode provided in the first embodiment includes the following steps:

[0027] Step 1. Prepare the patterned substrate:

[0028] Using photoresist reflow and inductively coupled plasma technology (ICP) to make a patterned substrate, specifically: first heat the photoresist mask to form a trapezoidal structure, and then use inductively coupled plasma The etching method etches a cone shape;

[0029] Step 2. Sputtering AlN nucleation layer:

[0030] Place the cleaned patterned substrate on a rotatable substrate, then place an aluminum target with a purity of 99.99% on the copper back plate of the reactive magnetron sputtering equipment, and draw the coating chamber into 2.5×10 -3 In the Pa vacuum chamber, pass high-purity inert gas Ar (99.999%), and start sputtering Al target at the same time, select RF power 13.65MHZ, control the sputtering rate of Al target to 5nm / min, at...

Embodiment 2

[0058] Such as figure 1 As shown, the method for preparing the epitaxial structure of the ultraviolet light emitting diode provided in the second embodiment includes the following steps:

[0059] Step 1. Prepare the patterned substrate:

[0060] The patterned substrate is made by photoresist reflow and inductively coupled plasma technology, specifically: the photoresist mask is first subjected to a thermal reflow process so that the photoresist forms a trapezoidal structure, and then the inductively coupled plasma is used for etching Method to etch a cone shape;

[0061] Step 2. Sputtering AlN nucleation layer:

[0062] Place the cleaned patterned substrate on a rotatable substrate, then place an aluminum target with a purity of 99.99% on the copper back plate of the reactive magnetron sputtering equipment, and draw the coating chamber into 2.5×10 -3 In the Pa vacuum chamber, pass high-purity inert gas Ar (99.999%), and start sputtering Al target at the same time, select RF power 13.6...

Embodiment 3

[0089] The method for preparing the epitaxial structure of the ultraviolet light emitting diode provided in the third embodiment includes the following steps:

[0090] Step 1. Prepare the patterned substrate:

[0091] The patterned substrate is made by photoresist reflow and inductively coupled plasma technology, specifically: the photoresist mask is first subjected to a thermal reflow process so that the photoresist forms a trapezoidal structure, and then the inductively coupled plasma is used for etching Method to etch a cone shape;

[0092] Step 2. Sputtering AlN nucleation layer:

[0093] Place the cleaned patterned substrate on a rotatable substrate, then place an aluminum target with a purity of 99.99% on the copper back plate of the reactive magnetron sputtering equipment, and draw the coating chamber into 2.5×10 -3 In the Pa vacuum chamber, pass high-purity inert gas Ar (99.999%), and start sputtering Al target at the same time, select RF power 13.65MHZ, control the sputtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com