Manufacturing method of LED (Light Emitting Diode) lamp bead

A technology of LED lamp beads and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor consistency, poor uniformity, and wide range of phosphor particle sizes of LED products, and reduce equipment cost. Requirements and operational difficulty, reduce production costs, and improve the effect of good rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

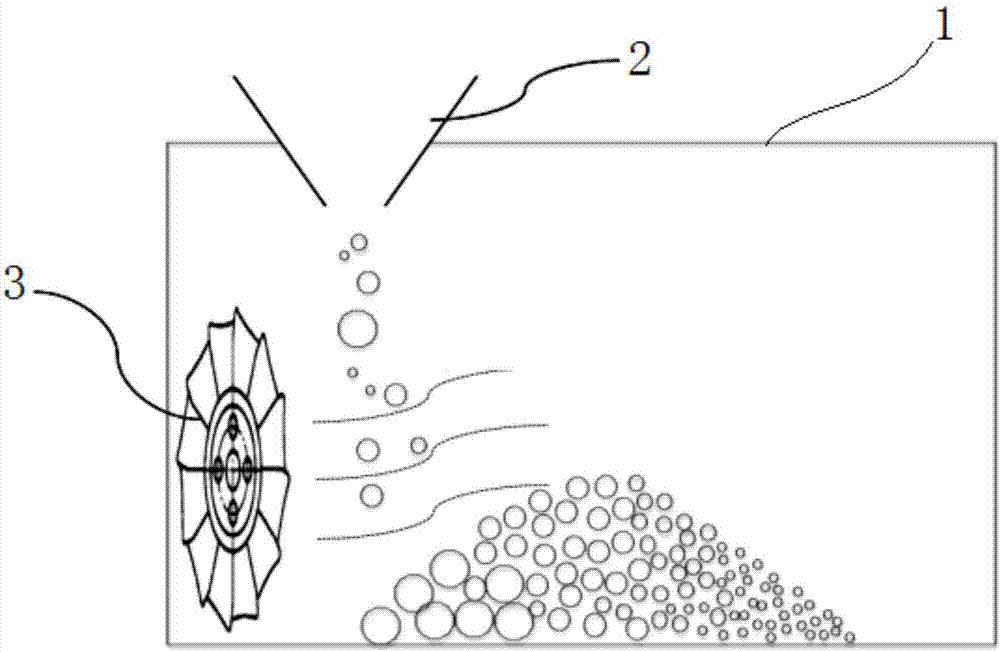

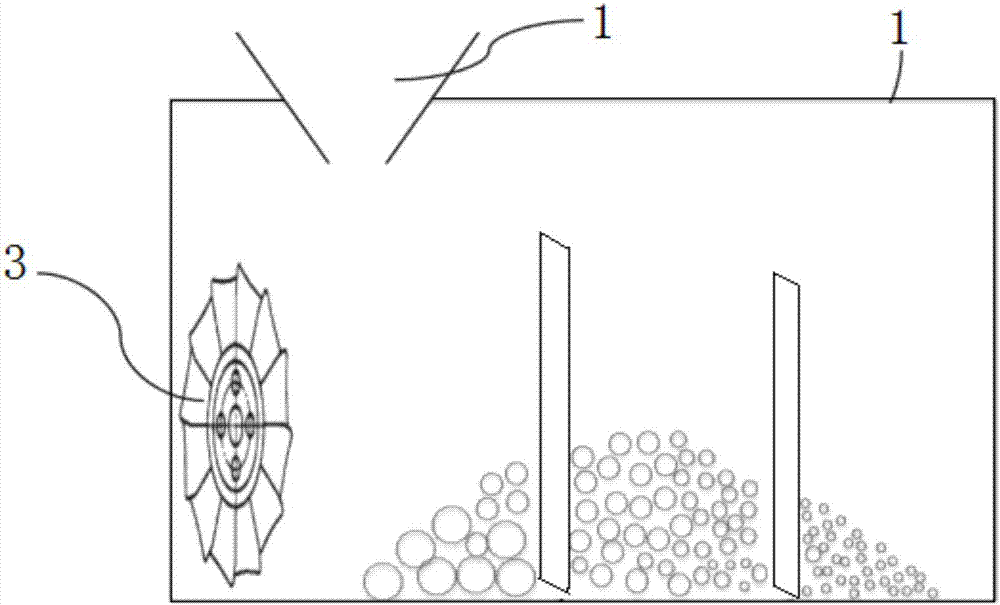

[0034] This embodiment provides a method for manufacturing LED lamp beads. Firstly, phosphor powder is screened by using a fluorescent powder air flow screening device. The structural schematic diagram of the air flow screening device is as follows figure 1 As shown, it includes a screening box 1, the top of the screening box 1 is provided with a feeding port 2 for putting in phosphor powder, and one side of the screening box 1 is provided with a blowing structure 3. The blower mechanism 3 is a conventional blower, and the blower mechanism 3 can be arranged inside the screening box 1 or communicated with the inside of the screening box 1 to blow the air flow into the screening box 1, which is arranged on the side close to the feeding port 2 , and can generate horizontal airflow.

[0035] This embodiment also provides a method for manufacturing an LED lamp bead, which includes the following steps:

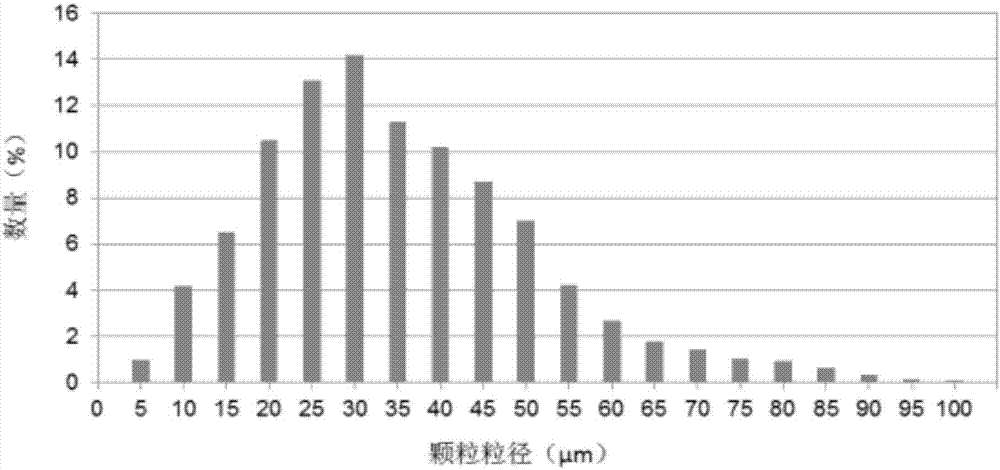

[0036] S1. The first fluorescent powder with a particle size of 0.1-100 μm is ...

Embodiment 2

[0042] This embodiment provides a method for manufacturing an LED lamp bead, which includes the following steps:

[0043] S1. The first fluorescent powder with a particle size of 0.1-100 μm is screened by the airflow screening device according to the particle size, and the first fluorescent powder is put into the feeding port 2 of the screening box 1, and the wind speed of the blowing mechanism 3 is blown. 5.5m / s, and the flow direction of the formed airflow is perpendicular to the falling direction of the phosphor powder. After the first phosphor powder falls from the feeding port 2, the airflow formed by the blower mechanism on the side of the feeding port 2 will sieve the first phosphor powder , classify and collect the first fluorescent powder to obtain a pile of fluorescent powder in the range of 3-10 kinds of particle sizes. In this embodiment, the first fluorescent powder is a phosphate phosphor doped with rare earth elements, which emits light The wavelength is 520nm; ...

Embodiment 3

[0049] This embodiment provides a method for manufacturing an LED lamp bead, which includes the following steps:

[0050] S1. The first fluorescent powder with a particle size of 0.1-100 μm is screened by the airflow screening device according to the particle size, and the first fluorescent powder is put into the feeding port 2 of the screening box 1, and the wind speed of the blowing mechanism 3 is blown. is 0.001m / s, and the flow direction of the formed airflow is perpendicular to the falling direction of the fluorescent powder. After the first fluorescent powder falls from the feeding port 2, the airflow formed by the blower mechanism on the side of the feeding port 2 sieves the first fluorescent powder. , classify and collect the first fluorescent powder, and obtain a pile of fluorescent powder in the range of 3-10 particle sizes. In this embodiment, the first fluorescent powder is a nitride phosphor powder doped with rare earth elements, which emits light The wavelength i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com