Memory alloy driving device by adoption of gas isolating cold and hot working media

A technology of memory alloy and gas isolation, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, non-rotating propulsion components, etc. It can solve the problems of nuclear fission risk, energy loss, pollution, etc., and achieve low operating costs and low cost , low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

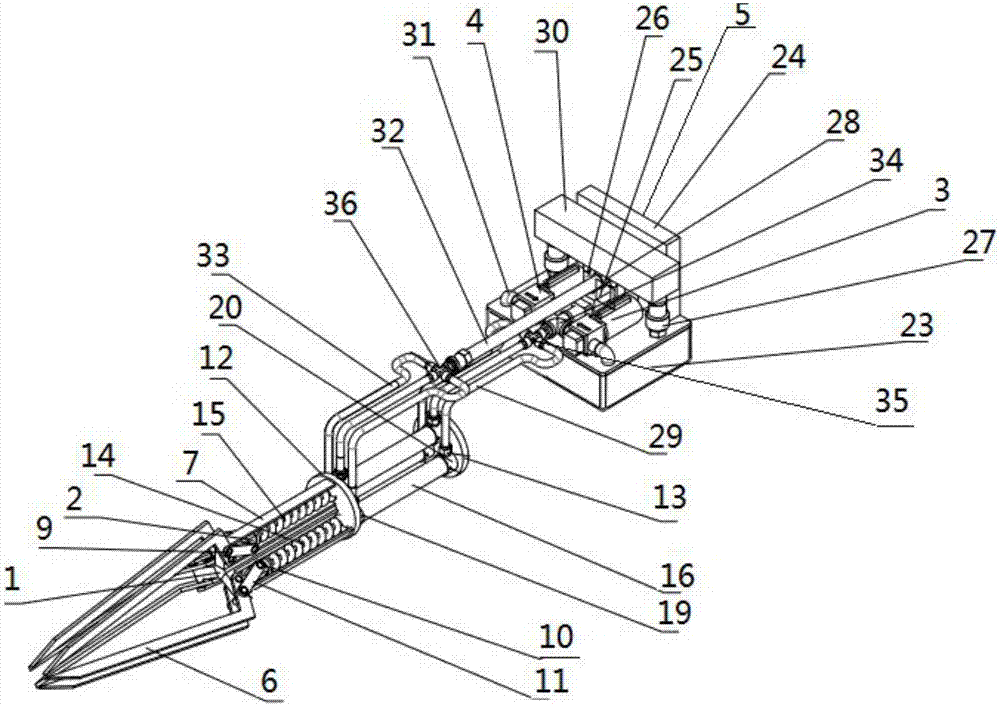

[0050] Such as Figure 1-Figure 7 Shown is a memory alloy driving device that uses gas to isolate cold and hot working fluids, including a moving structure 1, a driving structure 2, and a cold and hot water gas circulation control structure 5;

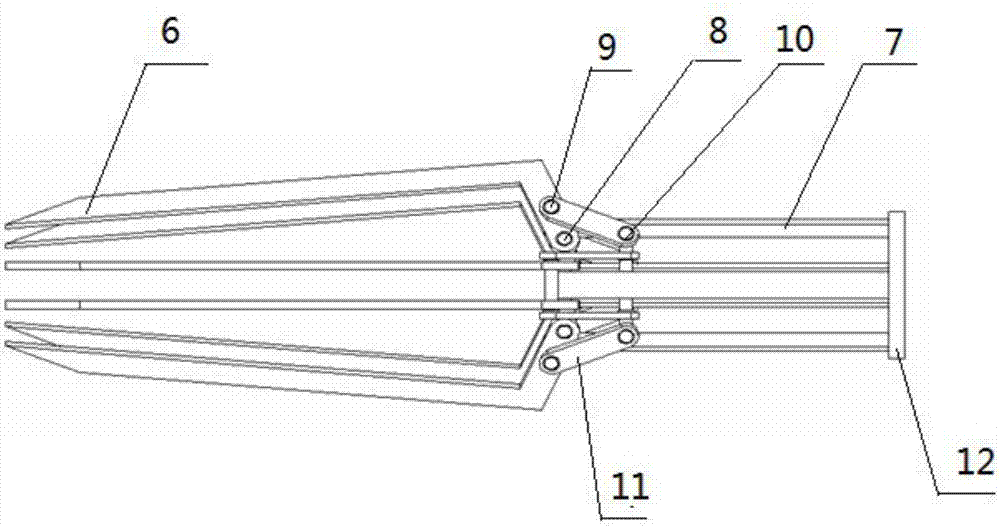

[0051] The moving structure 1 includes a paddle 6, a bracket stabilizer 7, a pin a8, a pin b9, a pin c10, and a connecting rod 11;

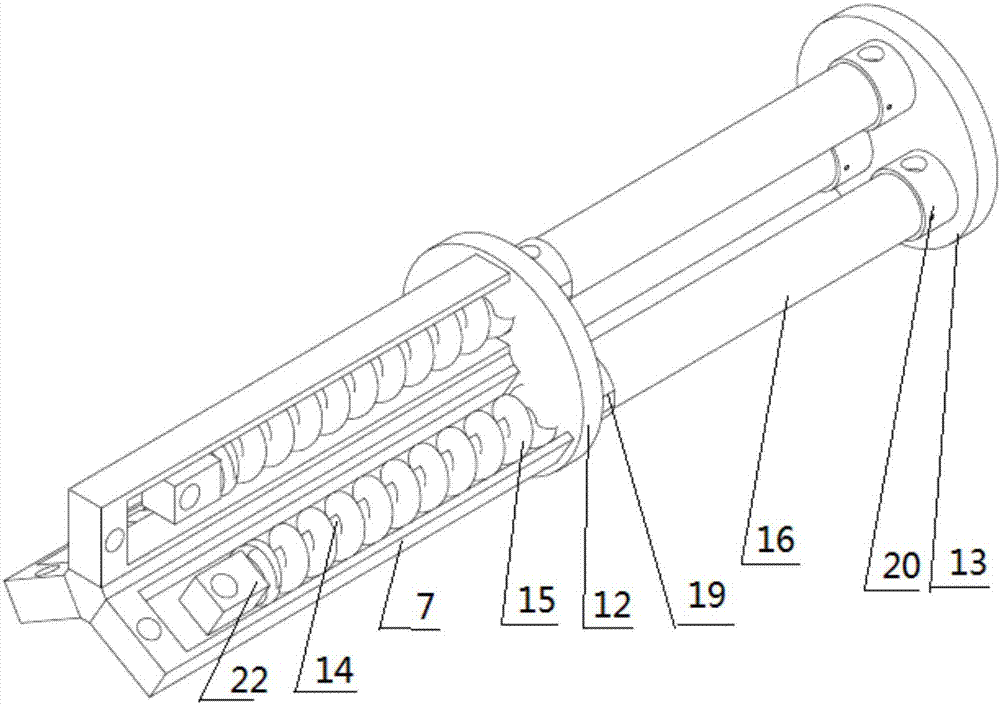

[0052]The driving structure 2 includes a front fixed disc 12, a rear fixed disc 13, a cylinder push rod 14, a compression spring 15 and a cylinder 16;

[0053] The front fixed disc 12 is provided with three threaded holes and three pairs of square holes, and the square holes are at both ends of each threaded hole for connecting the bracket stabilizer 7;

[0054] The rear fixed disc 13 is provided with three threaded holes;

[0055] The compression spring 15 is sleeved on the cylinder push rod 14;

[0056] One end of the cylinder push rod 14 is inserted into the cylinder 16 through the front fixed disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com