Treatment method of riboflavin fermentation liquid

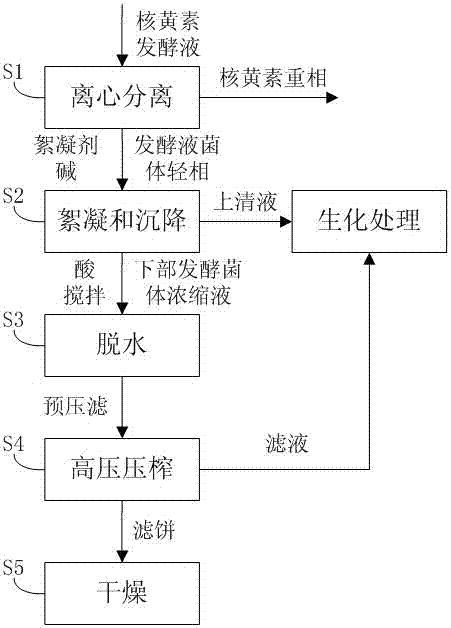

A processing method and riboflavin technology are applied in the processing field of riboflavin fermentation broth, can solve the problems of low filtration efficiency, inconvenient cleaning, low solid content of filter cake and the like, achieve simple operation, high separation efficiency and save production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 40,000L riboflavin fermentation broth was subjected to solid-liquid separation by high-efficiency centrifugation. Before separation, the morphology of riboflavin crystals and the morphology of bacteria were observed under a microscope. The riboflavin content in the mature riboflavin fermentation broth was 10779mg / L. Before centrifugation, the viscosity of the riboflavin fermented liquid is adjusted to about 130mpa, and the centrifugal speed is set at room temperature to be 3600 rpm. After separation, about 450L of concentrated riboflavin heavy phase was obtained, and about 33550L of fermented liquid cell light phase containing 600ppm riboflavin was obtained. The light phase of the fermentation liquid cell was observed under a microscope, and the basic morphology of riboflavin cell was basically the same as that before separation. Keeping consistent, the enrichment state of riboflavin cells is very good, and the riboflavin cells did not cause decomposition, breakage, etc....

Embodiment 2

[0044] 60,000L riboflavin fermentation liquid was subjected to high-efficiency centrifugation for solid-liquid separation. Before separation, the morphology of riboflavin crystals and the morphology of bacteria were observed under a microscope. The riboflavin content in the mature riboflavin fermentation liquid was 10385mg / L. The centrifugation process is the same as in Example 1. After separation, the concentrated about 700L riboflavin heavy phase is obtained, and about 59300L of the fermented liquid thallus light phase containing 500ppm riboflavin is observed under a microscope. The basic shape of the cells was basically the same as that before separation, and the enrichment state of the riboflavin cells was very good, and no decomposition or breakage of the riboflavin cells was caused. The light phase of the 59300L fermented liquid thallus contains about 1500kg of thalline, and the COD content is 58000mg / L. Sodium hydroxide aqueous solution is added to the light phase of the...

Embodiment 3

[0049] This implementation example adopts a kind of common plate and frame press filter to filter the fermented liquid thalline after concentration, is the comparative example of implementation example 2,

[0050] 60000L riboflavin fermentation broth was subjected to high-efficiency centrifugation for solid-liquid separation, and the riboflavin content in the mature riboflavin fermentation broth was 10385mg / L. The centrifugation treatment is the same as in Example 1. After separation, the concentrated heavy phase of about 700L riboflavin is obtained, and about 59300L of the fermented liquid thallus light phase containing 500ppm riboflavin is obtained. , COD content is 58000mg / L, in the fermented liquid thalline of this 59300L, add sodium hydroxide aqueous solution to regulate this fermented liquid thalline aqueous pH value to be 8-9, in this implementation example concrete pH is 8.9, in the situation of stirring Next, add the flocculant polyacrylamide anion PAM3000L with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com