Long-optical-path air chamber with stable encapsulation structure

A packaging structure, long optical path technology, applied in the field of long optical path gas chamber, can solve the problems of change, easy deformation, unstable optical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

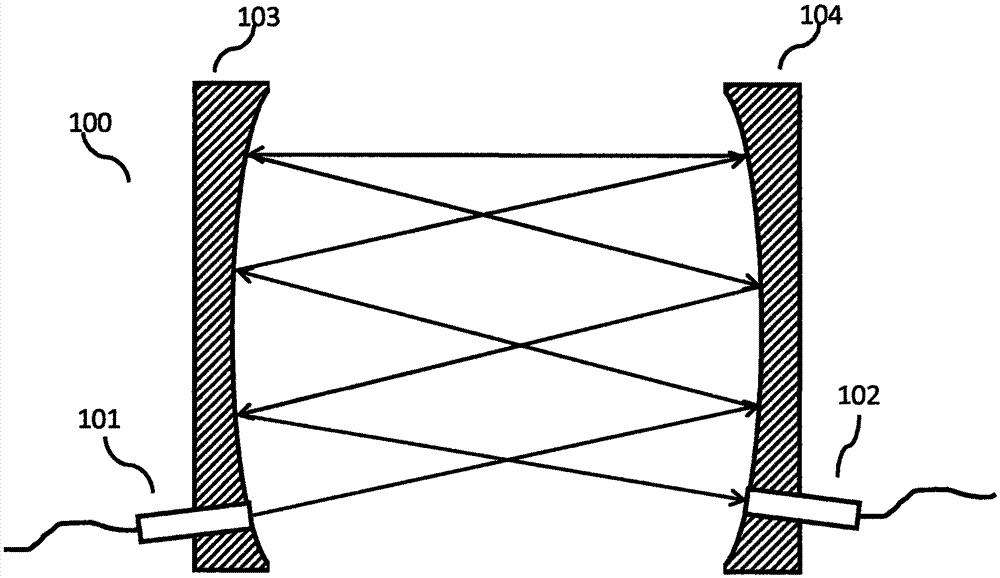

[0051] Such as Image 6 As shown, the long optical path gas chamber (600) provided by the present invention comprises:

[0052] 1. An input port (601) for inputting a light beam;

[0053] 2. An output port (602) for outputting light beams;

[0054] 3. A first concave reflector (603), having a first central hole, a first adhesive surface, and a first reflective surface, the first reflective surface having a first focal length f1;

[0055] 4. A second concave reflector (604), having a second central hole, a second bonding surface, and a second reflective surface, the second reflective surface having a second focal length f2;

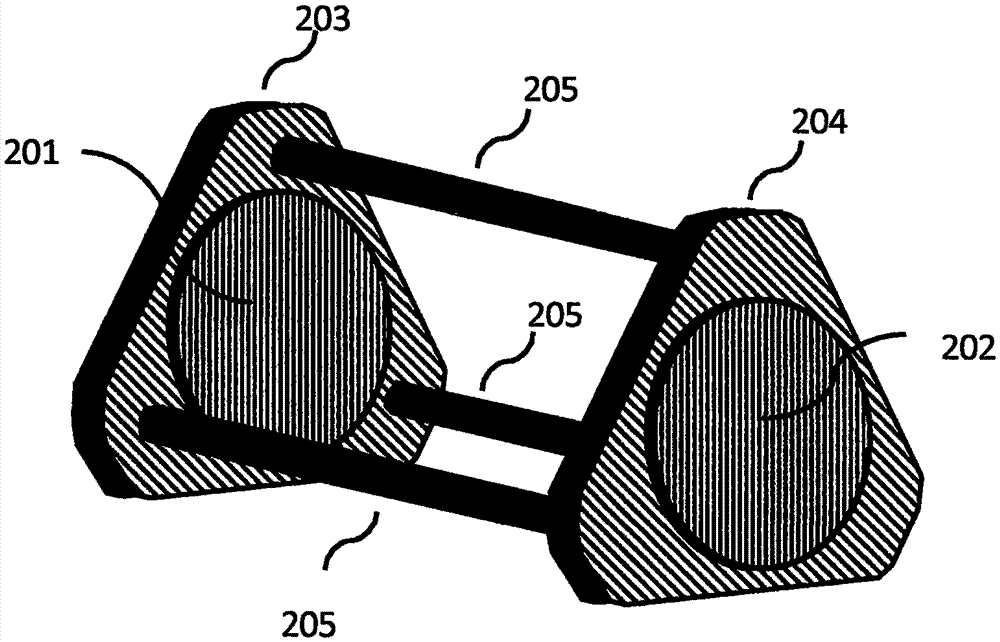

[0056] 5. A package post (605) having an outer diameter R and a length L;

[0057] 6. A first collar (606) having a first inner diameter R1 and a third bonding surface;

[0058] 7. A second collar (607) having a second inner diameter R2 and a fourth bonding surface.

[0059] The first and second reflective surfaces of the first and second concave mirr...

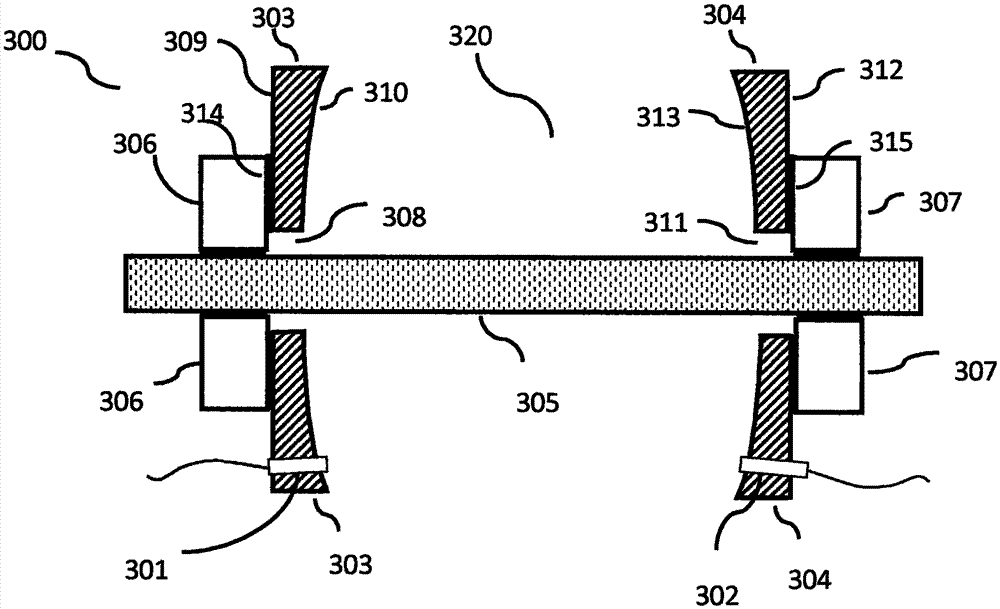

Embodiment 2

[0070] Such as Figure 7 As shown, the second embodiment of the long optical path gas cell (700) provided by the present invention has an optical and mechanical structure similar to that of embodiment 1, and optically adopts the Herriott gas cell configuration as well. The difference is that the outer package (709) is an open structure open to the ambient atmosphere, and no air inlet and outlet are needed, and the three columnar connecting rods (708) in the outer package connect the outer package The left and right parts are connected, Figure 7 Only two columnar connecting rods are drawn in .

[0071] The input end (701) is still an optical fiber collimator with a pigtail, and the laser beam collimated at the input end is fed into the reflection cavity through two total internal reflections of the parallelogram prism (707), and the first concave reflector ( 703) no longer needs to fix the small hole of the fiber collimator, and the fiber collimator and the parallelogram pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com