Automatic micro-sampling device and control method for electrophoresis detector

A technology of micro-sampling and detectors, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problem of different sample injection methods of electrophoresis detectors, the inability to establish standardized tests, and the inability to horizontally compare the tests of different instruments Results and other problems to achieve the effect of eliminating test results, rapid on-site detection, and ensuring accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

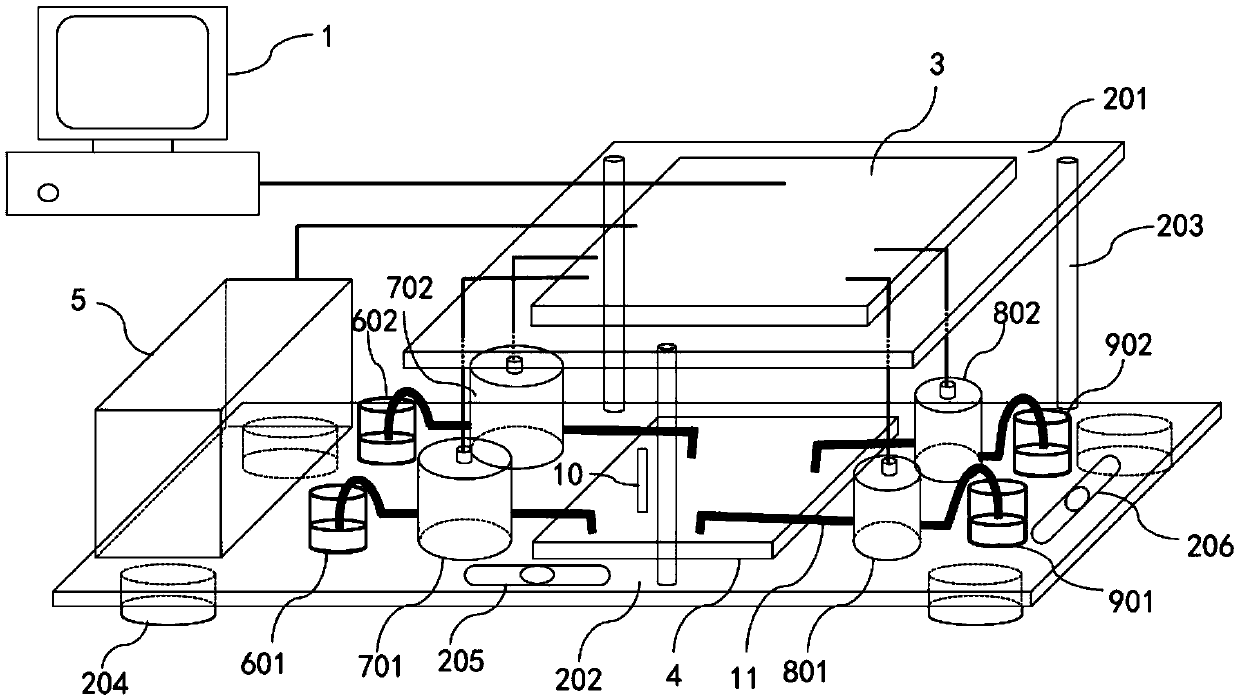

[0082] Example 1, the detection of inorganic cations based on non-contact capillary electrophoresis instrument

[0083] The fused silica capillary was used as the electrophoresis pipeline, and the concentration of inorganic cations in the unknown aqueous solution was tested by a non-contact conductivity detector.

[0084] The specific operation process is as follows:

[0085] 1) Preparation of buffer solution: Weigh 2.8-3.2 g of Tris (hydroxymethyl) aminomethane, Tris, and 0.16-0.20 g of ethylenediaminetetraacetic acid (EDTA) into a clean beaker, add Fully dissolve in ultrapure water, then add 0.25-0.35mL of glacial acetic acid (0.2mol / L), transfer to a 50ml volumetric flask, and dilute to volume with ultrapure water. Weigh 0.50-0.70 g of Polyvinyl pyrrolidone (PVP) into a 50 mL clean beaker, transfer to a 100 mL volumetric flask, add 2 mL of Tris-EDTA solution, and dilute to volume with ultrapure water. Take 40mL of the prepared buffer solution to the buffer solution bottle...

example 2

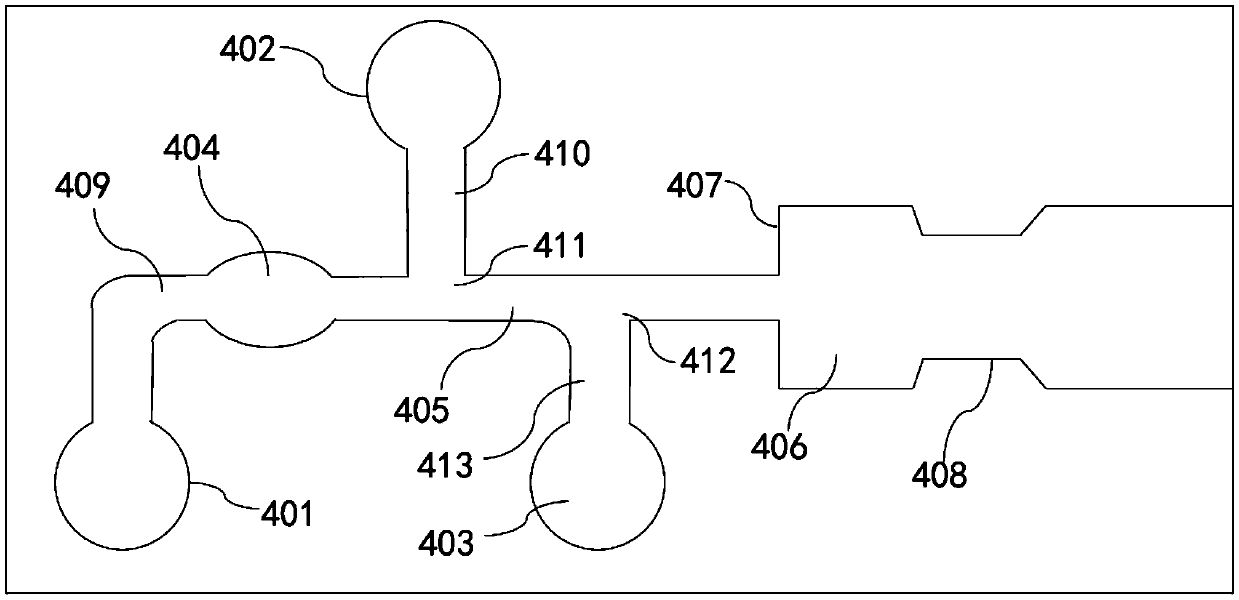

[0093] Example 2, Antibiotic Detection Based on Microfluidic Electrophoresis Chip

[0094] When the microfluidic electrophoresis chip is used, the end of the sample pool of the microfluidic sampling module is connected with the microfluidic outlet module to form an integral manufacturing mold during design and manufacture. Fluorescence intensity of cephradine after electrophoresis separation.

[0095] 1) Prepare borax-sodium hydroxide buffer solution: wherein the concentration of borax is 5.75-6.50 mmol / L, pH=9.3. Take the prepared buffer solution to the buffer solution bottle of the automatic sampling device.

[0096] 2) prepare the cephradine aqueous solution, and inject the sample solution into the sample bottle.

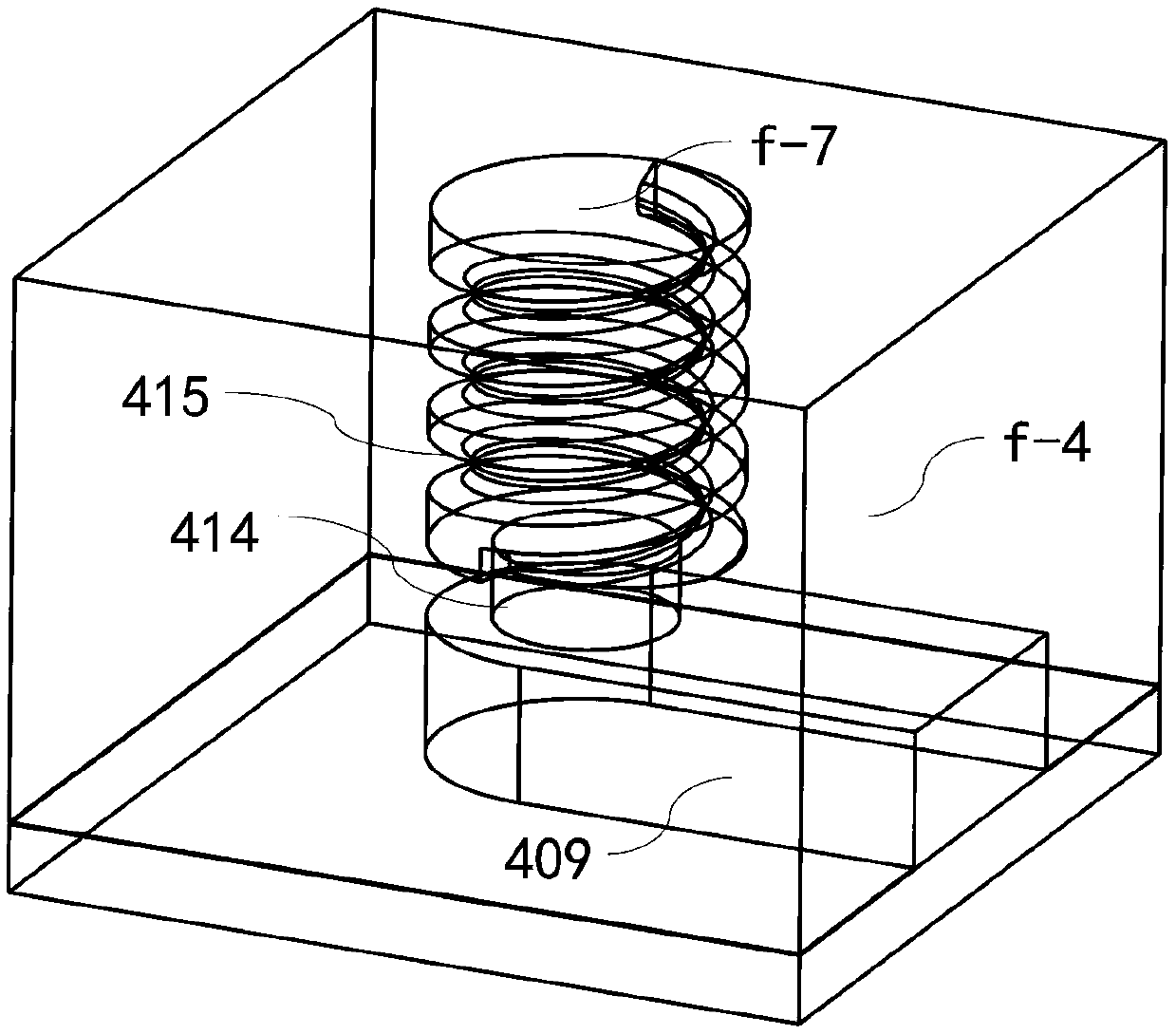

[0097] 3) Insert the clean capillary and the chemically inert tube into the corresponding interfaces of the microfluidic sampling module and the microfluidic sampling module respectively, place them on the lower layer of the PMMA double-layer support, and fix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com