Micro-porous starch composite styptic powder and preparation method thereof

A technology of microporous starch and hemostatic powder, which is applied in the fields of pharmaceutical formulations, surgical adhesives, applications, etc., can solve the problems of not being quickly absorbed by the human body, adverse reactions, and narrow application areas, and achieve good degradability, low cost, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

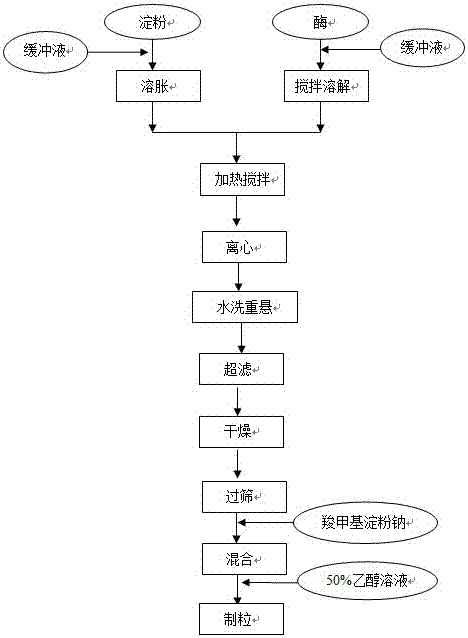

Method used

Image

Examples

Embodiment 1

[0019] Weigh 300g of starch and dissolve in 400ml of sodium acetate buffer, weigh 3g of α-amylase and 1.5g of glucoamylase respectively and dissolve in 200ml of sodium acetate buffer; Under ~5 conditions, react for 24 hours to prepare a microporous starch solution with a mass volume ratio of 50%. Centrifuge the microporous starch solution at a speed of 3000r / min for 5min to collect the centrifugal precipitate; add 30ml of purified water to resuspend the precipitate, then centrifuge at a rotational speed of 3000r / min for 5min, repeat the resuspension 3 times, and collect the final centrifugal precipitate (microporous starch) . Dissolve the centrifugal precipitate (microporous starch) in 100ml of purified water, stir for 10 minutes, and vacuum filter to obtain a filter cake; redissolve the filter cake in 200ml of purified water, stir for 10 minutes, and vacuum again to obtain a filter cake. The filter cake was dried in a drying oven at 50°C for 6 hours. After drying, it was sie...

Embodiment 2

[0021] Weigh 270g starch and dissolve in 400ml sodium acetate buffer, weigh 2.7g α-amylase and 1.35g glucoamylase respectively and dissolve in 200ml sodium acetate buffer; Under the condition of pH 4~5, react for 24 hours to prepare a microporous starch solution with a mass volume ratio of 45%. Centrifuge the microporous starch solution at a speed of 3000r / min for 5min to collect the centrifugal precipitate; add 25ml of purified water to resuspend the precipitate, then centrifuge at a rotational speed of 3000r / min for 5min, repeat the resuspension 3 times, and collect the final centrifugal precipitate (microporous starch) . Dissolve the centrifugal precipitate (microporous starch) in 100ml of purified water, stir for 10 minutes, and vacuum filter to obtain a filter cake; redissolve the filter cake in 200ml of purified water, stir for 10 minutes, and vacuum again to obtain a filter cake. The filter cake was dried in a drying oven at 50°C for 6 hours. After drying, it was sieve...

Embodiment 3

[0023] Weigh 330g starch and dissolve in 400ml sodium acetate buffer, weigh 3.3g α-amylase and 1.65g glucoamylase respectively and dissolve in 200ml sodium acetate buffer; Under the condition of pH 4~5, react for 24 hours to prepare a microporous starch solution with a mass volume ratio of 55%. Centrifuge the microporous starch solution at a speed of 3000r / min for 5min to collect the centrifugal precipitate; add 35ml of purified water to resuspend the precipitate, then centrifuge at a rotational speed of 3000r / min for 5min, repeat the resuspension 3 times, and collect the final centrifugal precipitate (microporous starch) . Dissolve the centrifugal precipitate (microporous starch) in 100ml of purified water, stir for 10 minutes, and vacuum filter to obtain a filter cake; redissolve the filter cake in 200ml of purified water, stir for 10 minutes, and vacuum again to obtain a filter cake. The filter cake was dried in a drying oven at 50°C for 6 hours. After drying, it was sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com