Method for preparing compound contaminated-soil in-situ repairing agent with abandoned biomass

A technology of waste biomass and in-situ remediation agent, applied in the restoration of polluted soil, etc., can solve the problems of complex soil pollution, low efficiency, and expensive in-situ remediation agent for complex polluted soil, and achieve environmental friendliness and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

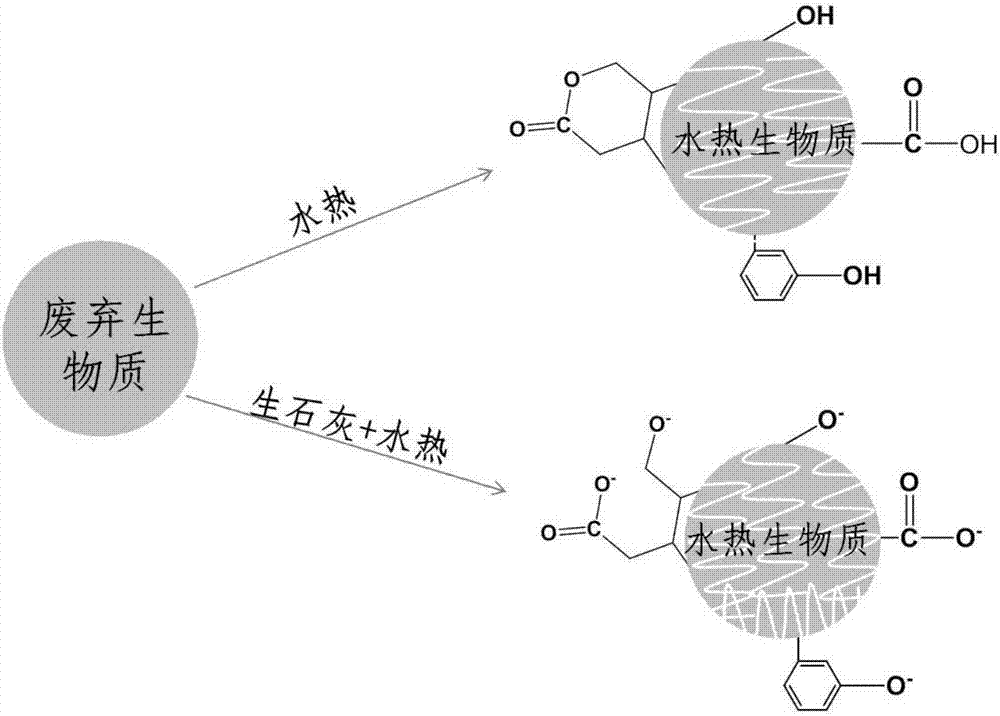

Method used

Image

Examples

Embodiment 1

[0021] 1. Material preparation

[0022] Crush the corn stalks to less than 5mm and set aside. PAHs (Σ2-ring PAHs 5261μg / kg; Σ3-ring PAHs 9220μg / kg; Σ4-ring PAHs 17301μg / kg; Σ5-ring PAHs 592μg / kg 5; Σ6-ring PAHs 2966μg / kg) and Cd (7.6mg / kg) pollution The soils were all taken from actual polluted soils (PAHs-contaminated soils were taken from coking plants; Cd-contaminated soils were taken from chemical smelters). After the soil samples were dried in a fume hood for 24 hours, the leaves, plant roots, and stones were removed, crushed, passed through a 2mm sieve, and stored in the dark.

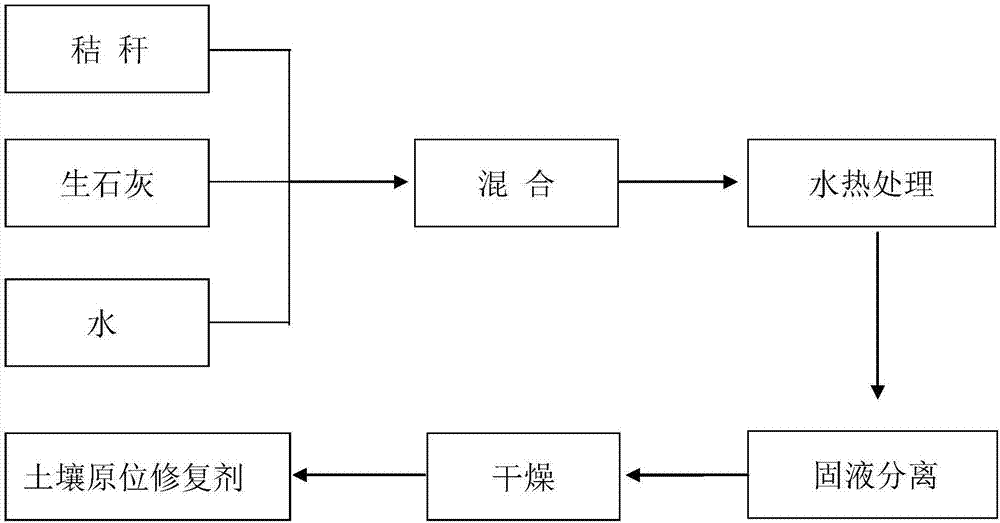

[0023] 2. Preparation of restoration agent

[0024] 1) Mix corn stalks (dry basis), quicklime, and water in a ratio of 4:1:20, then mechanically stir for 30 minutes;

[0025] 2) After the mixture is transferred to the hydrothermal reaction kettle, seal it;

[0026] 3) Heat the reactor to 220°C for hydrothermal treatment, stop heating after 40 minutes of hydrothermal treatment, and then cool d...

Embodiment 2

[0067] In addition to using pig manure instead of straw.

[0068] In the preparation of repairing agent 3), the reactor was heated to 240°C for hydrothermal treatment, and the hydrothermal treatment time was 60 minutes, which was the same as that of Example 1.

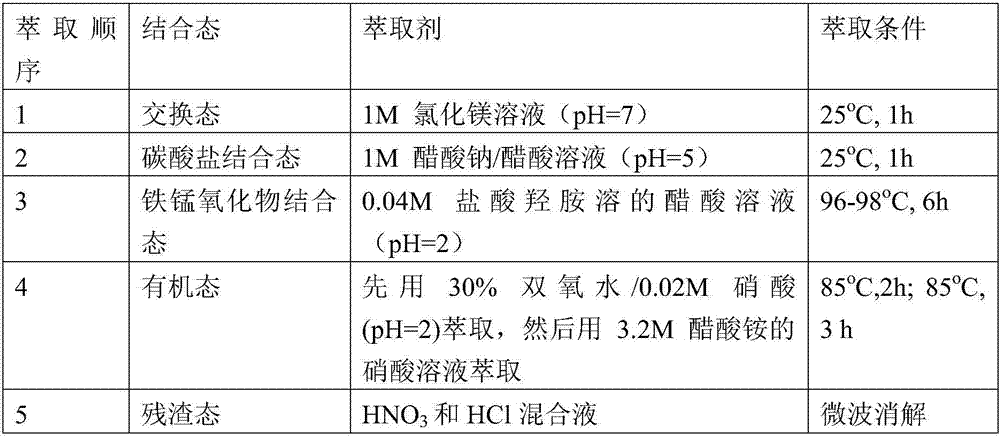

[0069] Table 1. Effect of remediation agents on Cd in soil.

[0070]

[0071]

[0072] Table 3 Effect of remediation agent on PAHs in soil

[0073]

[0074] As can be seen from Table 1, by adding the remediation agent prepared by the present invention to the Cd polluted soil, the Cd in the soil is transformed from the exchangeable state to the carbonate binding state, and the Cd in the soil is efficiently passivated. The highest passivation rate can reach 90%.

[0075] As can be seen from Table 3, the total amount of free state and bioavailable PAHs has been greatly reduced by adding the remediation agent prepared by the present invention in polluted soil, especially the total amount of free state PAHs, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com