Treatment method for waste phosphoric acid in electrode foil production

A treatment method and waste phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of waste of resources, waste of social resources, and large potential pollution of slag landfill environment, so as to achieve the effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

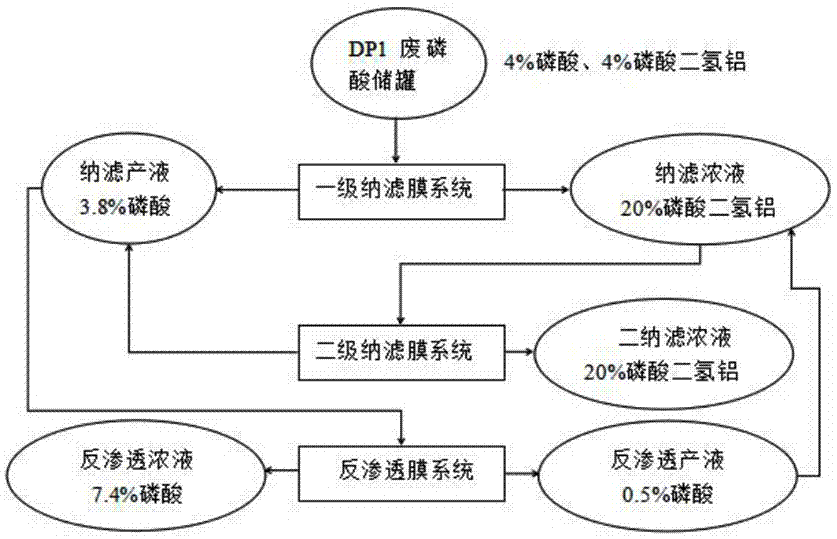

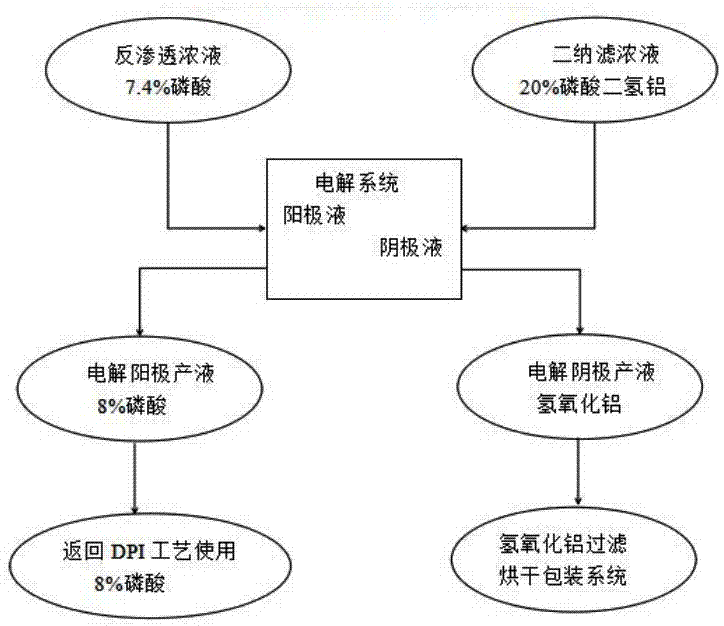

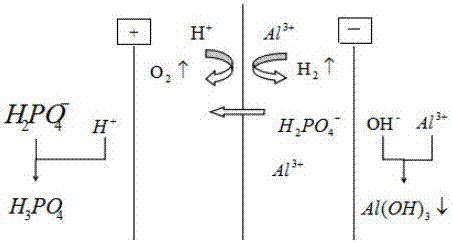

[0034] Such as figure 1 , figure 2 and image 3 Shown: the present invention comprises the following steps:

[0035] Step 1: Waste phosphoric acid in DP1 process, which contains 4% phosphoric acid and 4% aluminum dihydrogen phosphate, and some free phosphoric acid is separated by nanofiltration membrane. Taking 10m³DP1 waste phosphoric acid liquid as an example, 8m³capacitance grade phosphoric acid liquid containing 3.8% can be produced , the aluminum content is less than 100ppm (one ten-thousandth), and the chemical reaction formula of the remaining 2m3 mixed solution containing 4.8% phosphoric acid and 20% aluminum dihydrogen phosphate is as follows:

[0036] ;

[0037] Step 2: Multi-stage washing, filtering through the combination of reverse osmosis membrane and nanofiltration membrane, adopting the method of countercurrent washing, further washing the remaining 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com