Method for separating butanone-isopropanol-ethyl alcohol azeotrope through three-tower pressure-variable rectification

A technology for pressure swing rectification and separation of butanone, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., to achieve the effects of low equipment investment cost, low energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

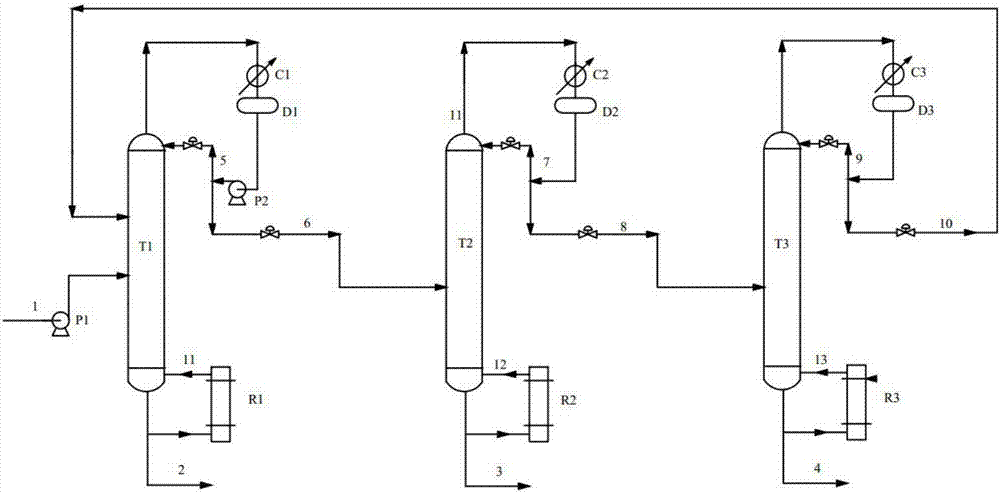

[0045] The feed flow rate is 1000kg / h, the temperature is 40°C, and the mass composition is: butanone 70%, isopropanol 10%, and ethanol 20%. The butanone column (T1) has a theoretical plate number of 34, the raw material liquid is introduced from the 26th plate, the circulating feed position is the 12th plate, the operating pressure is 4.0atm, the reflux ratio is 2.00, and the column diameter is about 490mm; The theoretical plate number of the isopropanol column (T2) is 100, and the production liquid at the top of the butanone column (T1) is introduced from the 44th plate, the operating pressure is 1.0atm, the reflux ratio is 7.50, and the column diameter is about 790mm; ethanol The number of theoretical plates in the tower (T3) is 30, and the production liquid from the top of the isopropanol tower (T2) is introduced from the 16th plate. The operating pressure is 0.4atm, the reflux ratio is 2.40, and the tower diameter is about 530mm. After separation and treatment, the purity...

Embodiment 2

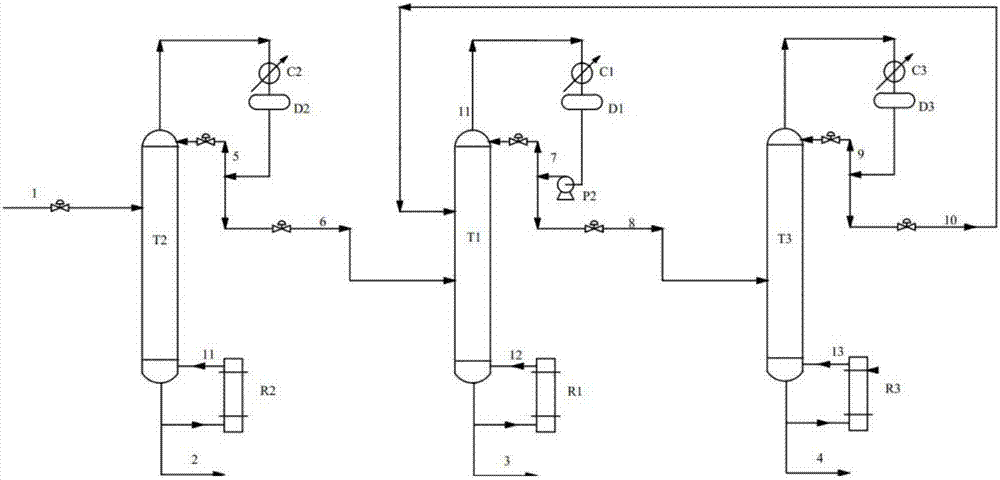

[0051] The feed flow rate is 1000kg / h, the temperature is 40°C, and the mass composition is: butanone 70%, isopropanol 10%, and ethanol 20%. The theoretical plate number of the isopropanol column (T2) is 77, the raw material liquid is introduced from the 19th plate, the operating pressure is 0.1atm, the reflux ratio is 1.80, and the column diameter is about 960mm; the theoretical plate number of the butanone column (T1) is There are 35 blocks, the production liquid at the top of the isopropanol tower (T2) is introduced from the 22nd plate, the circulating feed position is the 17th plate, the operating pressure is 5.8atm, the reflux ratio is 2.20, and the tower diameter is about 400mm; The number of theoretical plates of the ethanol column is 32, the production liquid from the top of the butanone column (T1) is introduced from the 13th plate, the operating pressure is 0.4atm, the reflux ratio is 2.10, and the column diameter is about 350mm. After separation and treatment, the p...

Embodiment 3

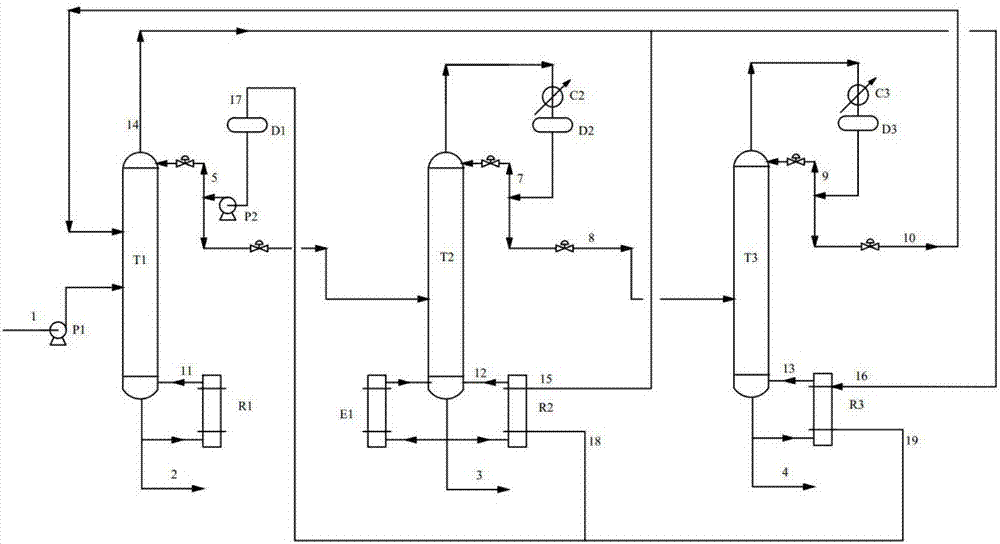

[0057] Such as image 3 As shown, the heat integration technology can be implemented in the separation sequence of butanone-isopropanol-ethanol three-column pressure swing rectification process, using the butanone column (T1) overhead steam to condense and release heat into the isopropanol column (T2) And the ethanol tower (T3) provides heat to achieve the purpose of saving energy and reducing consumption and reducing equipment investment. Butanone tower (T1) among the figure is the high-pressure tower of operating pressure 4atm, and the butanone product that purity can reach 99.9wt% is extracted at the bottom of the tower, and the tower top is butanone-isopropanol-ethanol azeotrope, and the tower top temperature is 118.08°C. The isopropanol tower (T2) tower is the atmospheric tower of operating pressure 1.0atm, and the isopropanol product with purity up to 99.3wt% is produced at the bottom of the tower, and the tower top is a methyl ethyl ketone-ethanol mixture containing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com