A method and device for circulating and purifying impurity gas in a low positive pressure sealing molding room

A gas circulation and impurity gas technology, applied in chemical instruments and methods, separation methods, measuring devices, etc., can solve the problems of threatening the personal safety of operators, filter clogging, and short working life, so as to improve collection efficiency and reduce filtration. Effects of net abrasion and reduction of accumulation clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

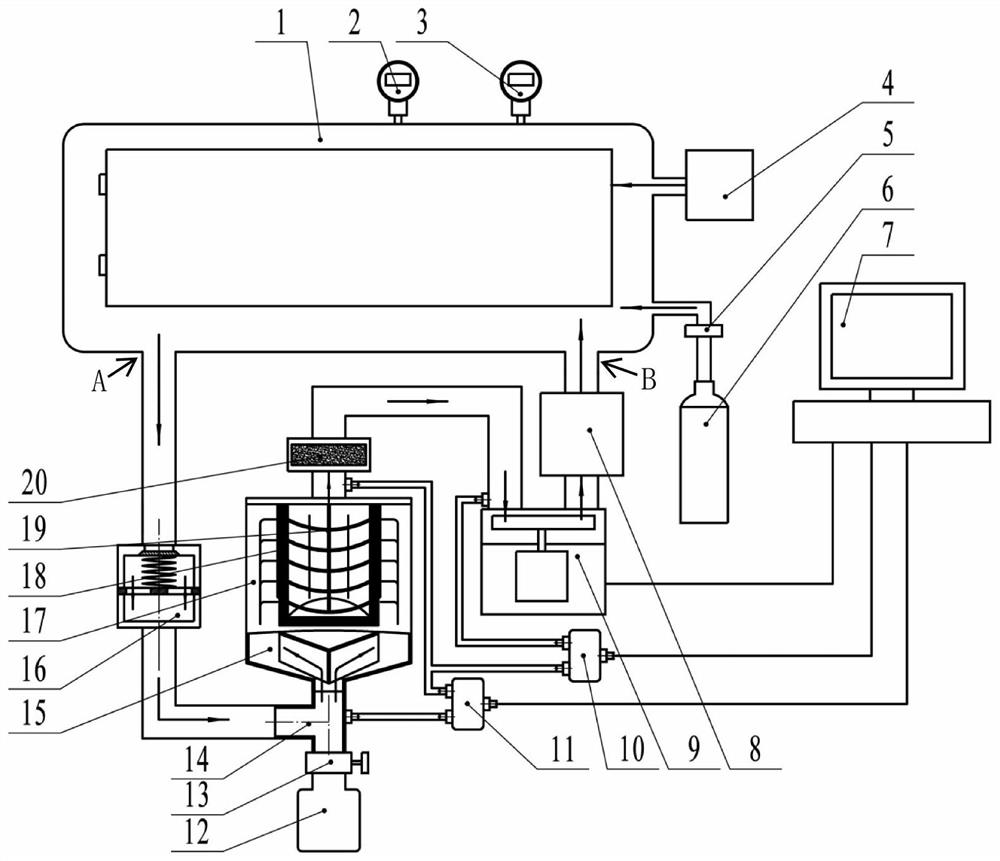

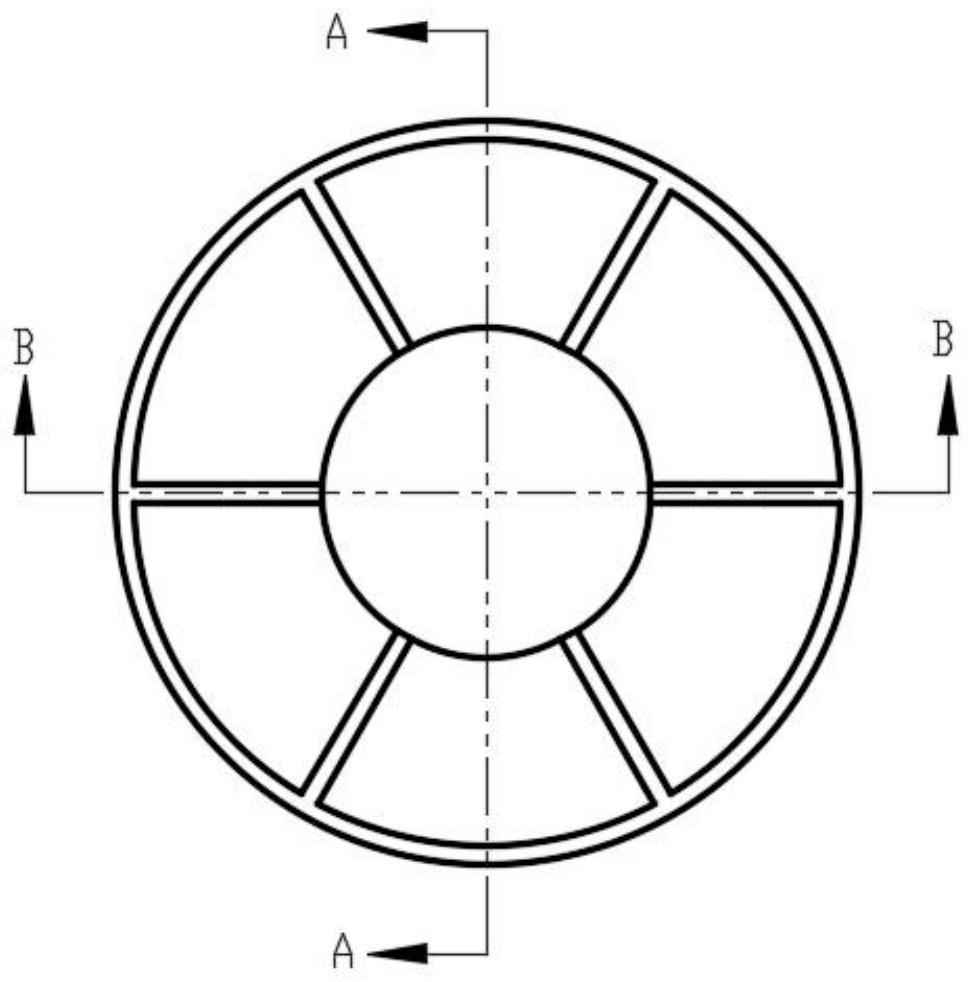

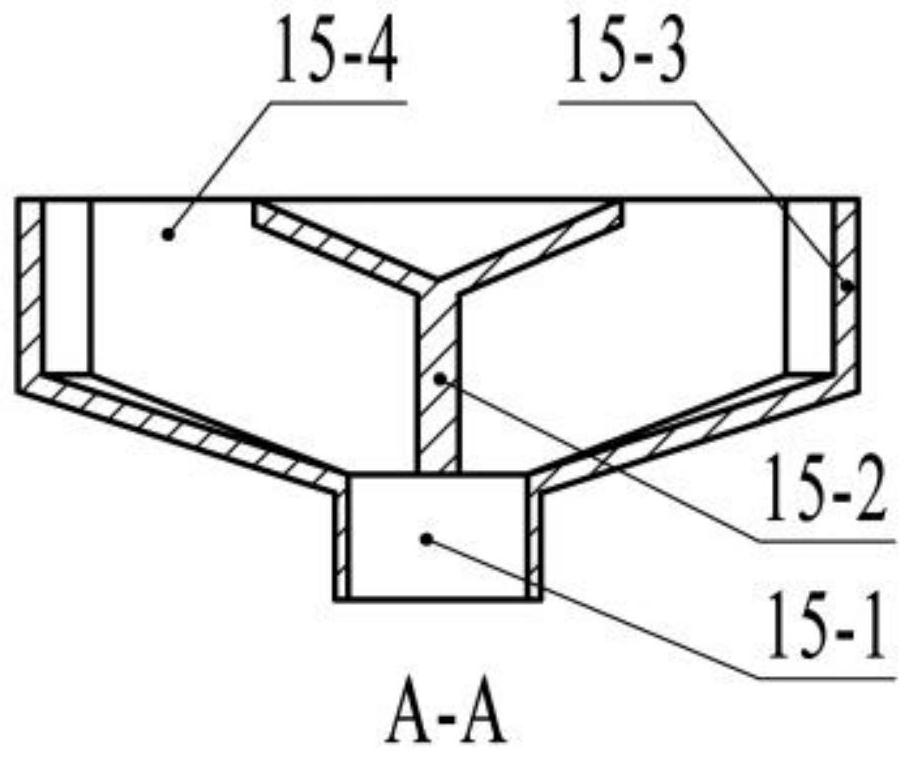

[0049] like Figures 1 to 7 shown. The invention discloses a low positive pressure sealed molding chamber impurity gas circulation purification device, comprising a molding chamber 1 and its gas circulation purification system, the gas circulation purification system is controlled by a computer 7; two ends of the inner cavity of the molding chamber 1 are respectively provided There are gas circulation outlet A and gas circulation inlet B;

[0050] The gas circulation purification system includes a first one-way gas valve 16, a three-way pipe 14, a gas distribution device 15, a filter box 17, an activated carbon filter box 20, a circulating air pump 9, a second one-way gas valve 8, a first pressure a differential sensor 10, a second differential pressure sensor 11;

[0051] The gas circulation outlet A is sequentially connected to the first one-way gas valve 16, the three-way pipe 14, the gas uniform distribution device 15, the filter box 17, the activated carbon filter box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com