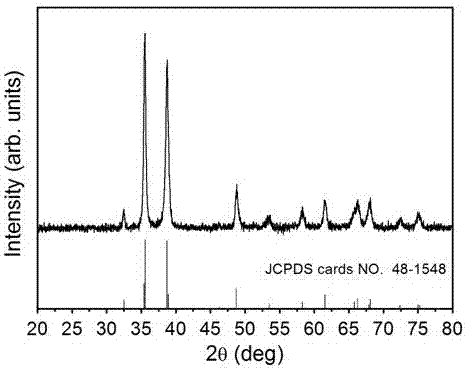

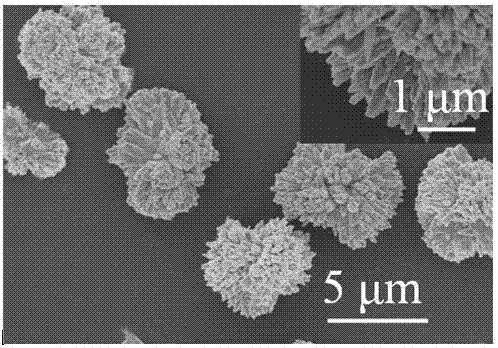

Method for preparing flower-shaped CuO microsphere and application of flower-shaped CuO microsphere in formaldehyde gas sensor

A sensor and microsphere technology, applied in the field of preparation of CuO microspheres, can solve problems such as large-scale application and expensive detection equipment, and achieve good response-recovery characteristics and selectivity, good crystallization, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] (1) The preparation method of the flower-shaped CuO microspheres comprises the following steps:

[0024] Step 1: A certain amount of Cu(NO 3 ) 2 •3H 2 O, urea, and PEG20000 were dissolved in 80 mL of deionized water. Stir magnetically at room temperature for 30 minutes, and prepare a hydrothermal synthesis precursor reaction solution.

[0025] Step 2: Transfer the precursor reaction solution prepared in Step 1 into a polytetrafluoroethylene-lined stainless steel autoclave with a filling degree of 80% and seal it. Keep the temperature at 120-200°C for 12 hours, then cool down to room temperature with the furnace to obtain the reaction product.

[0026] Step 3: The reaction product obtained in Step 2 is centrifuged, washed repeatedly with distilled water and absolute ethanol, and then dried.

[0027] Step 4: Put the dried product in Step 3 into a muffle furnace and calcinate at 400° C. for 3 hours to obtain flower-shaped CuO microspheres.

[0028] (2) The steps of p...

Embodiment 1

[0034] (1) Preparation of flower-like CuO microspheres:

[0035] Step 1: 0.483 g Cu(NO 3 ) 2 ·3H 2 O, 0.36 g of urea, and 1.784 g of PEG20000 were dissolved in 80 mL of deionized water, and magnetically stirred at room temperature for 30 minutes to prepare a reaction solution of the precursor for hydrothermal synthesis.

[0036] Step 2: Transfer the precursor reaction solution prepared in Step 1 into a polytetrafluoroethylene-lined stainless steel autoclave with a filling degree of 80%, and seal it.

[0037] Step 3: Put the reaction kettle in Step 2 in an oven, keep it warm at 180° C. for 12 hours, and then cool it down.

[0038] Step 4: Centrifuge the reactant solution prepared in Step 3 to obtain a black precipitate, which is then repeatedly washed with distilled water and absolute ethanol.

[0039] Step 5: Place the product of Step 4 in a drying oven at a constant temperature at 80° C. for 24 hours for drying.

[0040] Step 6: Put the dried product in step 5 into a cle...

Embodiment 2

[0045] (1) Preparation of flower-like CuO microspheres:

[0046] Step one, two are with embodiment 1.

[0047] Step 3: Place the reaction kettle in Step 2 in an oven, keep it warm at 120° C. for 12 hours, and then cool it down.

[0048] Steps 4, 5 and 6 are the same as in Example 1.

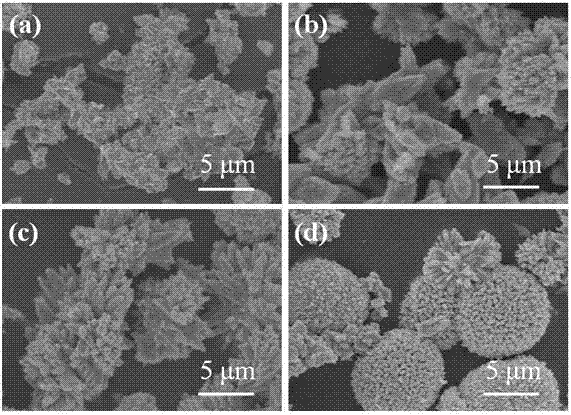

[0049] (2) Structural characterization of flower-like CuO microspheres

[0050] The morphology of the product was characterized by scanning electron microscopy. Such as image 3 As shown in (a), the product is a bulk material composed of nanoblocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com