Improved method for preparing sodium lauryl sulfate

A technology of sodium lauryl sulfate and sulfamic acid, which is applied in the preparation of sulfate esters, organic chemistry, etc., and can solve problems such as irritation, harm, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

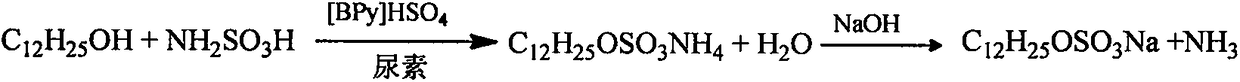

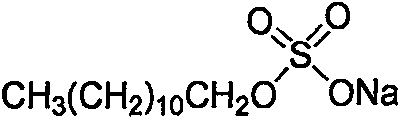

[0015] The preparation of embodiment 1, sodium lauryl sulfate, structural formula is as follows:

[0016]

[0017] Add 6.64g of raw material lauryl alcohol and 1.94g of sulfamic acid in a 100ml round bottom flask, and dissolve the raw materials under stirring conditions, and then add 1-butylpyridine bisulfate ([BPy]HSO 4 ) (structural formula is: ) 0.3884 g of acidic ionic liquid and 0.48 g of urea were used as catalysts, and stirred and reacted at 90° C. for 4 h. After the reaction was completed, it was treated with 30% NaOH solution to neutrality. After drying, it was washed with absolute ethanol and chloroform to obtain 3.69 g of pure white powder sodium lauryl sulfate, with an isolated yield of 64.0% and a melting point of 183 -185°C.

[0018] Identification of Sodium Lauryl Sulfate:

[0019] Infrared Spectrum IR(KBr)v / cm -1 : 2957, 2919, 2851, 1249, 1205, 830.

[0020] The product was identified to be consistent with the literature report.

Embodiment 2

[0022] Add 6.64g of raw material lauryl alcohol and 1.94g of sulfamic acid in a 100ml round bottom flask, and dissolve the raw materials under stirring conditions, and then add 1-butylpyridine bisulfate ([BPy]HSO 4 ) (structural formula is: ) 0.3884 g of acidic ionic liquid and 0.48 g of urea were used as catalysts, and stirred and reacted at 95° C. for 2 h. After the reaction was completed, it was treated with 30% NaOH solution to neutrality, and after drying, it was washed with absolute ethanol and chloroform to obtain 4.56 g of pure white powder sodium lauryl sulfate, with an isolated yield of 79.1% and a melting point of 183 -185°C.

[0023] The product was identified to be consistent with the literature report.

Embodiment 3

[0025] Add 6.64g of raw material lauryl alcohol and 1.94g of sulfamic acid in a 100ml round bottom flask, and dissolve the raw materials under stirring conditions, and then add 1-butylpyridine bisulfate ([BPy]HSO 4 ) (structural formula is: ) 0.3884 g of acidic ionic liquid and 0.48 g of urea were used as catalysts, and stirred and reacted at 100° C. for 4 h. After the reaction was completed, it was treated with 30% NaOH solution to neutrality, and after drying, it was washed with absolute ethanol and chloroform to obtain 5.30 g of pure white powder sodium lauryl sulfate, with an isolated yield of 91.9% and a melting point of 183 -185°C.

[0026] The product was identified to be consistent with the literature report.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com