Preparation method for strengthening responses of titanium dioxide nanotubes to visible light

A technology of titanium dioxide and nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of few reports, no promotion value, expensive materials, etc., and achieve the convenience of operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

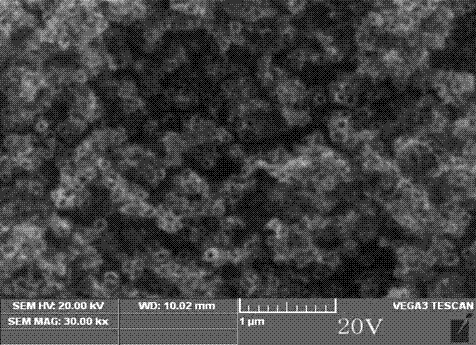

[0032] The first step is to cut out a titanium piece with a size of 20mm×15mm×1mm and a purity of 99.99%. Polish the titanium sheet with 120#, 240#, 400#, 600#, 800#, 000#, 1200# waterproof sandpaper in sequence, ultrasonically clean it in deionized water and ethanol for 2 minutes, and then chemically clean it in 0.02M hydrogen fluoride aqueous solution Polishing for 30s.

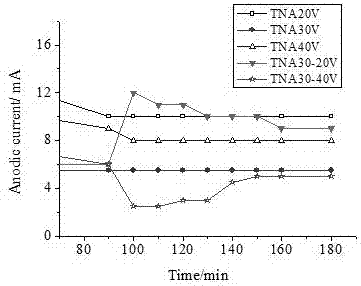

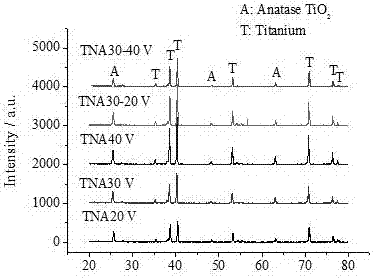

[0033] The second step is the anodic oxidation of the second step voltage. The pretreated titanium sheet was used as the anode, and a stainless steel sheet with an area 10 times the area of the titanium sheet was used as the cathode, which was put into the oxidizing solution for anodic oxidation, and the distance between the cathode and the anode was 5 cm.

[0034] The oxidation solution is a solution system in which ammonium fluoride is dissolved in glycerin and water, the mass percentage of ammonium fluoride is 0.5%, and the volume ratio of glycerin and water is 1:1.

[0035] The oxidation voltage is ...

Embodiment 2

[0039] The first step is to cut out a titanium piece with a size of 20mm×15mm×1mm and a purity of 99.99%. Polish the titanium sheet with 120#, 240#, 400#, 600#, 800#, 000#, 1200# waterproof sandpaper in sequence, ultrasonically clean it in deionized water and ethanol for 2 minutes, and then chemically clean it in 0.02M hydrogen fluoride aqueous solution. Polishing for 30s.

[0040] The second step is the anodic oxidation of the second step voltage. The pretreated titanium sheet was used as the anode, and a stainless steel sheet with an area 10 times the area of the titanium sheet was used as the cathode, which was put into the oxidizing solution for anodic oxidation, and the distance between the cathode and the anode was 5 cm.

[0041] The oxidation solution is a solution system in which ammonium fluoride is dissolved in glycerin and water, the mass percentage of ammonium fluoride is 0.5%, and the volume ratio of glycerin and water is 1:1.

[0042] The oxidation voltage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com