Light controllable type quantum dot backlight source

A quantum dot and backlight technology, which is applied in the field of optically controllable quantum dot backlight, can solve the problems of uneven light mixing of blue light sources, poor thermal stability of quantum dots, and poor uniformity of outgoing light, etc., to increase the efficiency of quantum dots, Effects of increasing light absorption efficiency and shortening the path of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

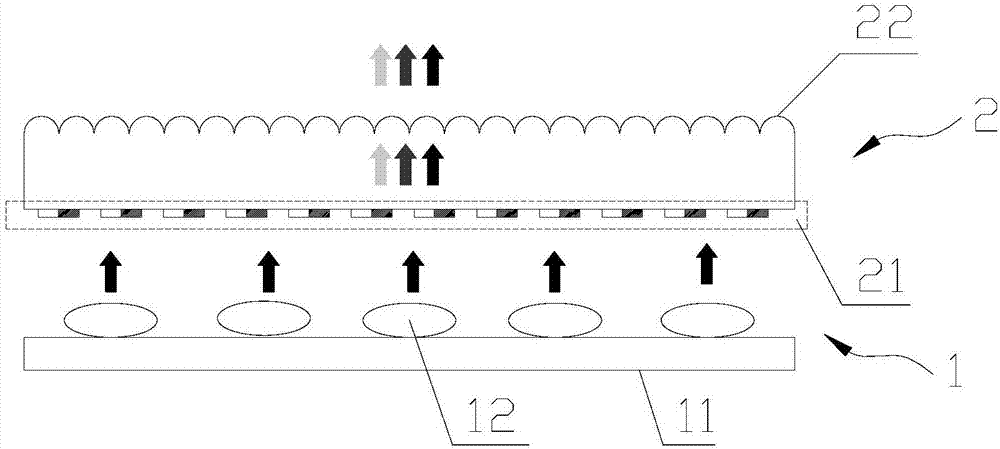

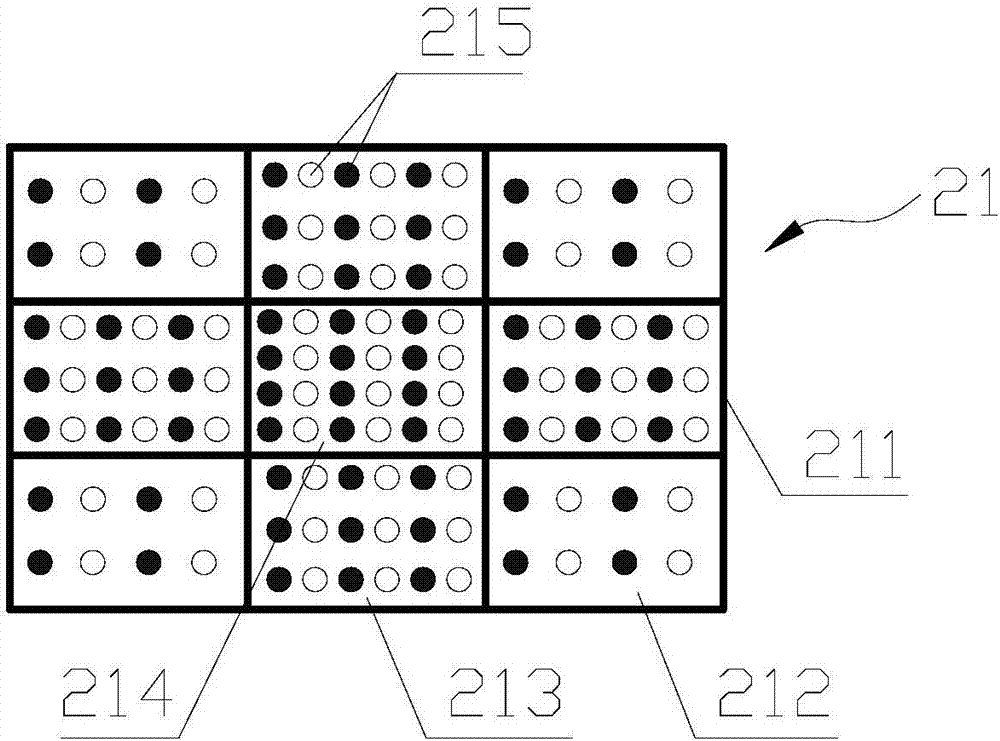

[0031] Such as Figure 1-2 As shown, an optically controllable quantum dot backlight of the present invention includes sequentially stacked blue light source components 1 and an optical plate 2, a quantum dot layer 21 is provided on the light incident end surface of the optical plate 2, and the optical A microstructure 22 is provided on the light emitting end surface of the plate 2, and the microstructure 22 is a convex lens structure. The microstructure 22 performs primary light mixing, and has the functions of light guiding and light concentrating. The blue light source assembly 1 also has multiple implementations. In this embodiment, two types of structures are provided: di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com