Method for recycling and preparing lithium titanate negative electrode material from waste lithium titanate battery

A technology of lithium titanate battery and negative electrode material, which is applied in battery recycling, battery electrode, waste collector recycling and other directions, can solve the problems of complex process, difficult industrialization of lithium titanate material recovery, and inability to achieve large-scale industrialization, etc. Process controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

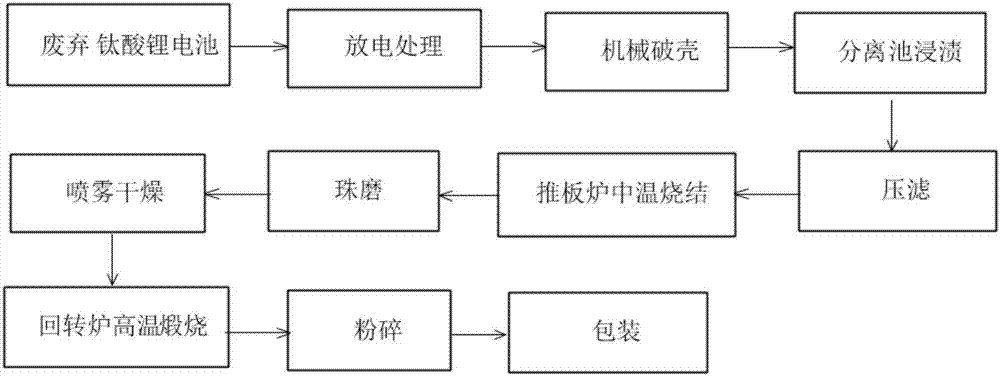

Method used

Image

Examples

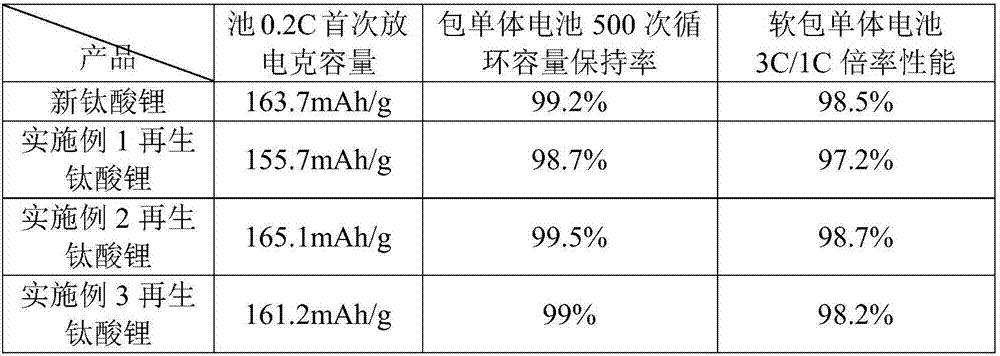

Embodiment 1

[0038] Put 500kg of lithium titanate battery pole pieces that have been discharged and separated into the separation pool. The solvent of the separation pool is a mixed solvent of NMP, DMF and acetone with a mass ratio of 1:1:1. The temperature of the separation pool is 55°C, and the immersion time is For 24 hours, the separation cell ultrasonically turns on the high-frequency mode. The current collector was washed, dried and recovered, and the battery slurry solution in the separation tank was transferred to a filter press to separate the battery slurry solution from solid to liquid, and the moisture content of the separated mixture was detected to be 10.2%. Put the mixture obtained by pressure filtration into a pusher furnace, sinter at 500°C for 4.5 hours, pass compressed air all the time during the sintering process, and cool to room temperature with the furnace to obtain lithium titanate from which the carbon material conductive agent has been removed.

[0039] Re-add lit...

Embodiment 2

[0042] Put 500kg of lithium titanate battery pole pieces that have been discharged and separated into the separation pool. The solvent of the separation pool is a mixed solvent of NMP, DMF and acetone with a mass ratio of 1:1:1. The temperature of the separation pool is 55°C, and the immersion time is For 24 hours, the separation cell ultrasonically turns on the high-frequency mode. The current collector was washed, dried and recovered, and the battery slurry solution in the separation tank was transferred to a filter press to separate the battery slurry solution from solid to liquid, and the moisture content of the separated mixture was detected to be 11.7%. Put the mixture obtained by pressure filtration into a pusher furnace, sinter at 500°C for 4.5 hours, pass compressed air all the time during the sintering process, and cool to room temperature with the furnace to obtain lithium titanate from which the carbon material conductive agent has been removed.

[0043]Re-add lith...

Embodiment 3

[0046] Put 500kg of lithium titanate battery pole pieces that have been discharged and separated into the separation pool. The solvent of the separation pool is a mixed solvent of NMP, DMF and acetone with a mass ratio of 1:1:1. The temperature of the separation pool is 55°C, and the immersion time is For 24 hours, the separation cell ultrasonically turns on the high-frequency mode. The current collector was washed, dried and recovered, and the battery slurry solution in the separation tank was transferred to a filter press to separate the battery slurry solution from solid to liquid, and the moisture content of the separated mixture was detected to be 9.7%. Put the mixture obtained by pressure filtration into a pusher furnace, sinter at 500°C for 4.5 hours, pass compressed air all the time during the sintering process, and cool to room temperature with the furnace to obtain lithium titanate from which the carbon material conductive agent has been removed.

[0047] Re-add lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com