Titanium/tricalcium phosphate/titanium mesh composite material for bone implantation material, and preparation method thereof

A technology of bone implant material and tricalcium phosphate, which is applied in the field of titanium/tricalcium phosphate/titanium mesh composite material and its preparation, can solve the problems of reducing the mechanical properties of materials and the growth of titanium grains, and achieve excellent mechanical properties, Excellent compressive strength, the effect of improving the speed and ability of bone repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

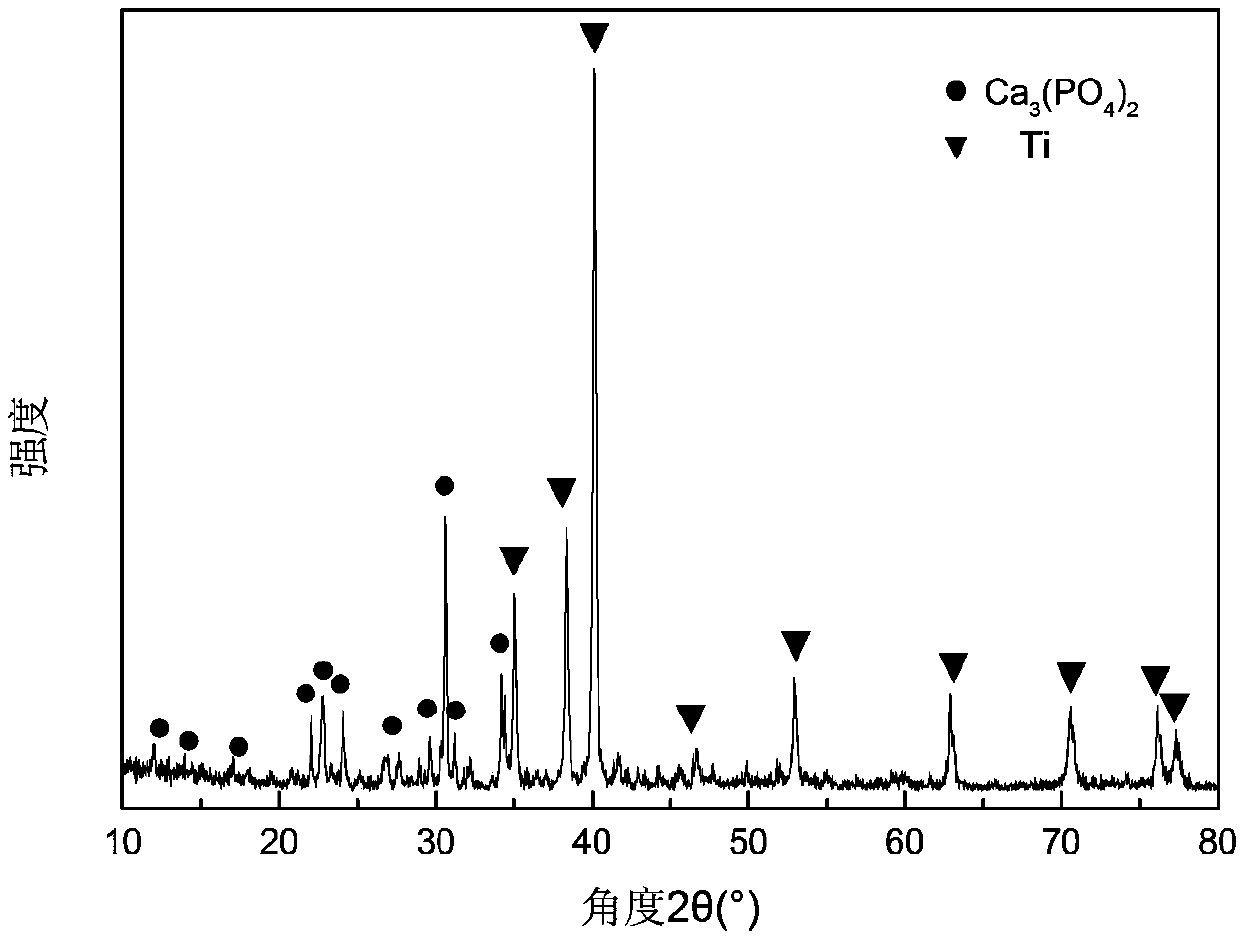

[0047] A titanium / tricalcium phosphate / titanium mesh composite material applied to bone implant materials according to the present invention has a continuous network structure, wherein the mass ratio of titanium to tricalcium phosphate is 5:5, and the titanium mesh accounts for 5% of the composite material mass. 10wt%, tricalcium phosphate is α-TCP, titanium mesh is 40 mesh.

[0048] The preparation method of the present embodiment titanium / tricalcium phosphate / titanium mesh composite material comprises the following steps:

[0049] (1) Mixing of titanium and tricalcium phosphate: mix commercial pure titanium powder and α-TCP powder according to the mass ratio of 5:5, add stearic acid at the same time, carry out ball milling for 4 hours, the rotating speed of ball milling is 200r / min;

[0050] (2) Titanium / tricalcium phosphate / titanium mesh composite material sintering: the titanium / tricalcium phosphate mixed powder prepared by step 1) is packed into the titanium mesh skelet...

Embodiment 2

[0052] A titanium / tricalcium phosphate / titanium mesh composite material applied to bone implant materials according to the present invention has a continuous network structure, wherein the mass ratio of titanium to tricalcium phosphate is 6:4, and the titanium mesh accounts for 2% of the composite material mass. 15wt%, titanium mesh number is 40 mesh.

[0053] The preparation method of the present embodiment titanium / tricalcium phosphate / titanium mesh composite material comprises the following steps:

[0054] (1) Mixing of titanium and tricalcium phosphate: mix commercial pure titanium powder and α-TCP powder according to the mass ratio of 6:4, add stearic acid at the same time, carry out ball milling for 4 hours, the rotating speed of ball milling is 200r / min;

[0055] (2) Titanium / tricalcium phosphate / titanium mesh composite material sintering: the titanium / tricalcium phosphate mixed powder prepared by step 1) is packed into the titanium mesh skeleton that the mesh number ...

Embodiment 3

[0058] A titanium / tricalcium phosphate / titanium mesh composite material applied to bone implant materials according to the present invention has a continuous network structure, wherein the mass ratio of titanium to tricalcium phosphate is 7:3, and the titanium mesh accounts for 2% of the composite material mass. 20 wt%, tricalcium phosphate is α-TCP, titanium mesh is 60 mesh.

[0059] The preparation method of the present embodiment titanium / tricalcium phosphate / titanium mesh composite material comprises the following steps:

[0060] (1) Mixing of titanium and tricalcium phosphate: mix commercial pure titanium powder and α-TCP powder according to the mass ratio of 7:3, add stearic acid at the same time, carry out ball milling for 4 hours, the rotating speed of ball milling is 200r / min;

[0061] (2) Titanium / tricalcium phosphate / titanium mesh composite material sintering: the titanium / tricalcium phosphate mixed powder prepared by step 1) is packed into the titanium mesh skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com