A passivator for reducing the activity of heavy metals in livestock and poultry manure and its application

A technology of livestock and poultry manure and passivating agent, which is applied in the application, preparation of organic fertilizers, agriculture, etc., can solve the problems of reduced utilization efficiency, secondary pollution, and restricted application, so as to prevent agglomeration effect, improve utilization efficiency, and high The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

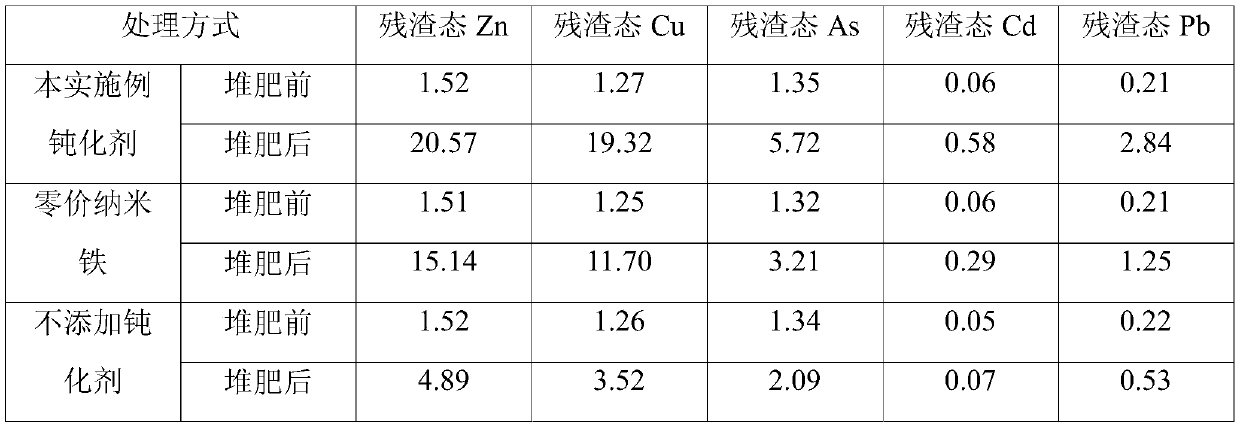

Examples

Embodiment 1

[0022] Preparation of Passivator for Reducing Heavy Metal Activity in Livestock and Poultry Manure

[0023] (1) Preparation of solid conditioner: uniformly mix fly ash, phosphogypsum and red mud according to a weight ratio of 48:27:22 to obtain a solid conditioner;

[0024] (2) Preparation of liquid stabilizer: under nitrogen atmosphere and mechanical stirring (rotating speed 400r / min), rhamnolipid solution (2g / L) and FeCl 3 After the solution (0.2mol / L) was fully mixed, it was added dropwise with FeCl 3 solution with an equal volume of NaHB 4 Solution (0.4mol / L) was reacted, and after the bubbles were no longer generated, the reaction was completed, and the rhamnolipid-coated zero-valent nano-iron suspension was obtained, which was sealed and stored at room temperature.

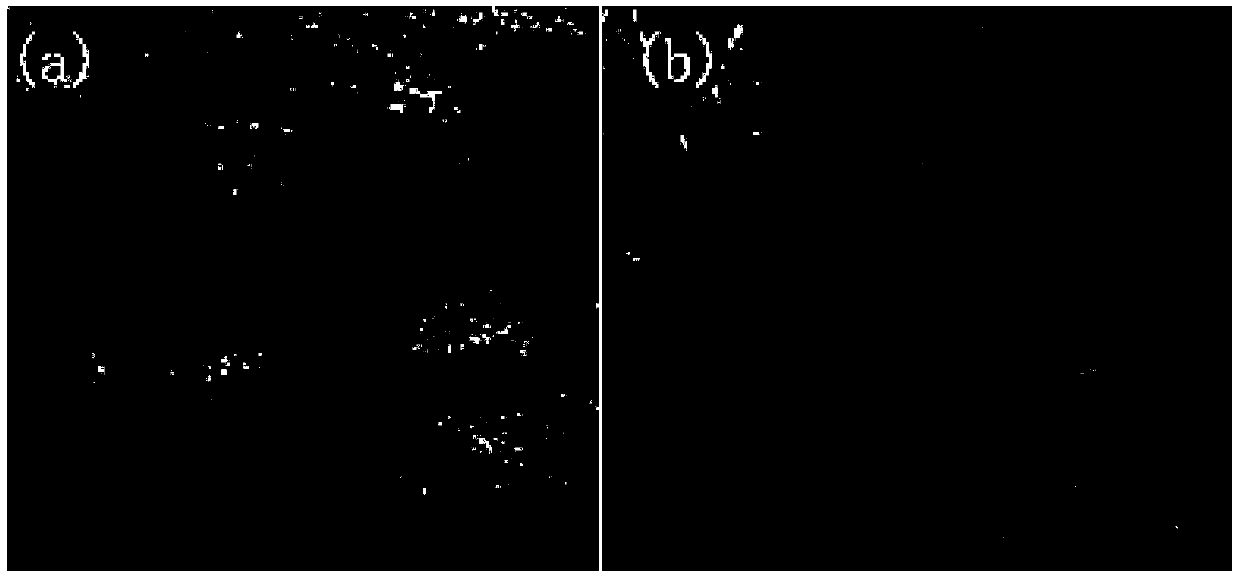

[0025] figure 1 The scanning electron microscope image of the rhamnolipid-coated zero-valent nano-iron suspension prepared for this example, it can be seen from the figure that the zero-valent nano-iron p...

Embodiment 2

[0032] Preparation of Passivator for Reducing Heavy Metal Activity in Livestock and Poultry Manure

[0033] (1) Preparation of solid conditioner: uniformly mix fly ash, phosphogypsum and red mud according to a weight ratio of 45:26:25 to obtain a solid conditioner;

[0034] (2) Preparation of liquid stabilizer: under nitrogen atmosphere and mechanical stirring (rotating speed 500r / min), rhamnolipid solution (3g / L) and FeCl 3 After the solution (0.25mol / L) was fully mixed, it was added dropwise with FeCl 3solution with an equal volume of NaHB 4 Solution (0.5mol / L) was reacted, and after the bubbles were no longer generated, the reaction was completed, and the rhamnolipid-coated zero-valent nano-iron suspension was obtained, which was sealed and stored at room temperature.

[0035] Application for passivation of heavy metals in chicken manure

[0036] Add the passivating agent used in this example to reduce the activity of heavy metals in livestock and poultry manure to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com