Compound phosphorus-nitrogen series flame-retardant polyamide and preparation method thereof

A technology of flame-retardant polyamide and phosphorus-nitrogen flame retardant, which is applied in the field of compound phosphorus-nitrogen flame-retardant polyamide and its preparation, which can solve the problems of inability to form a dense protective layer, low condensed phase carbon content, and lower product grades, etc. problems, to achieve the effect of reducing secondary hazards, improving flame retardant effect, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

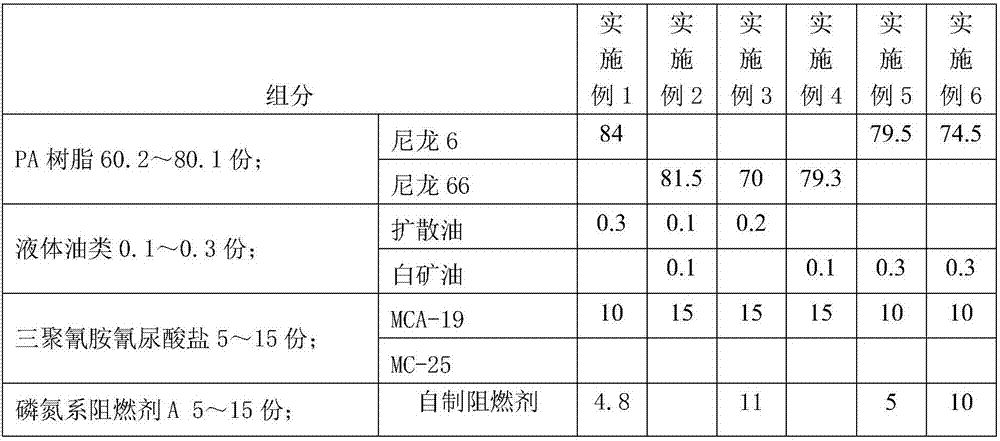

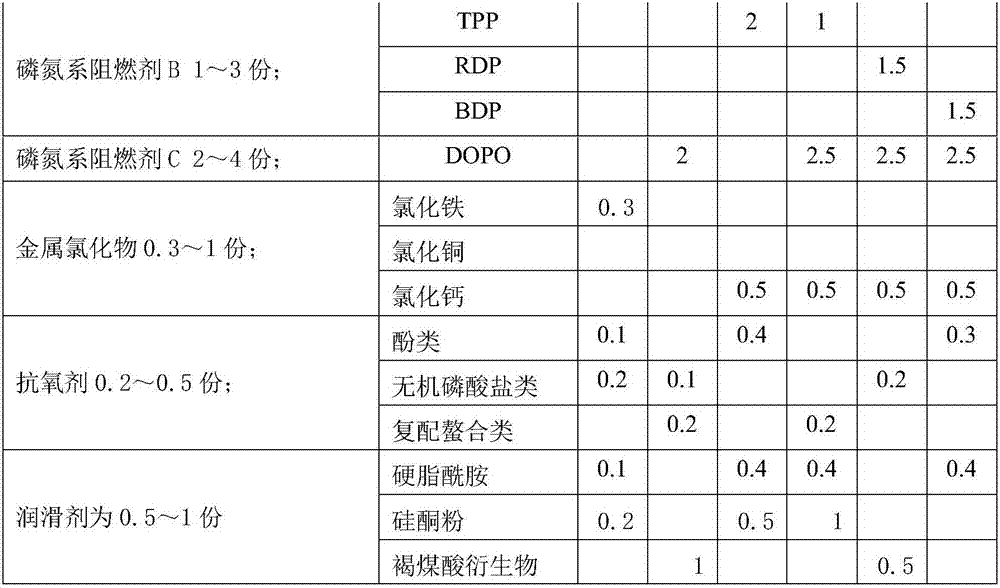

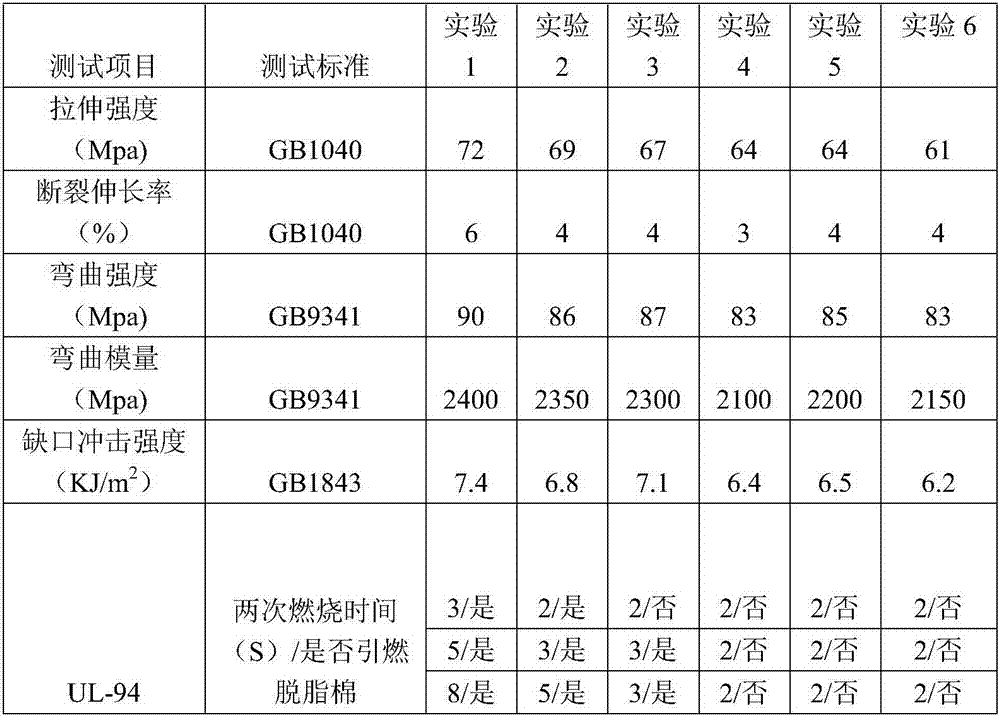

[0036] The preparation method of a compound phosphorus nitrogen flame retardant polyamide of the present invention is illustrated in conjunction with specific examples:

[0037] The steps of embodiment 1-6 are as follows

[0038] (1) Processing and mixing of raw materials: PA resin is baked at 110°C for 2 hours, and the moisture content is controlled below 0.1. Sequence and ratio Place in a high-speed mixer and stir at high speed for 3-5 minutes to fully mix the components;

[0039] (2) Melt extrusion: Add the mixed materials into the twin-screw extruder, the screw temperature: 220°C in the first zone, 250°C in the second zone, 245°C in the third zone, 240°C in the fourth zone, 230°C in the fifth zone, and 230°C in the sixth zone 235°C, 240°C in the seventh zone, 245°C in the eighth zone, 250°C in the die head, melt extrusion, and the screw speed is 320 rpm;

[0040] (3) Granulation and post-processing: the extruded material is water-cooled, air-dried, pelletized, and magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com