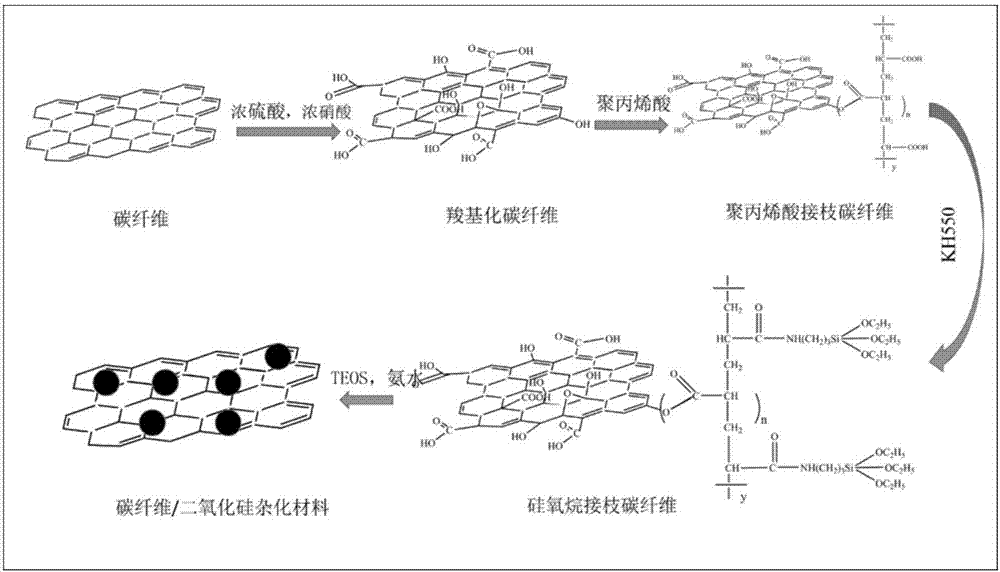

Carbon fiber/silica hybrid material and preparation method thereof

A hybrid material, silica technology, applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of matrix material combination, the effect is not obvious, etc., to increase the specific surface area, increase adsorption, improve grafting rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

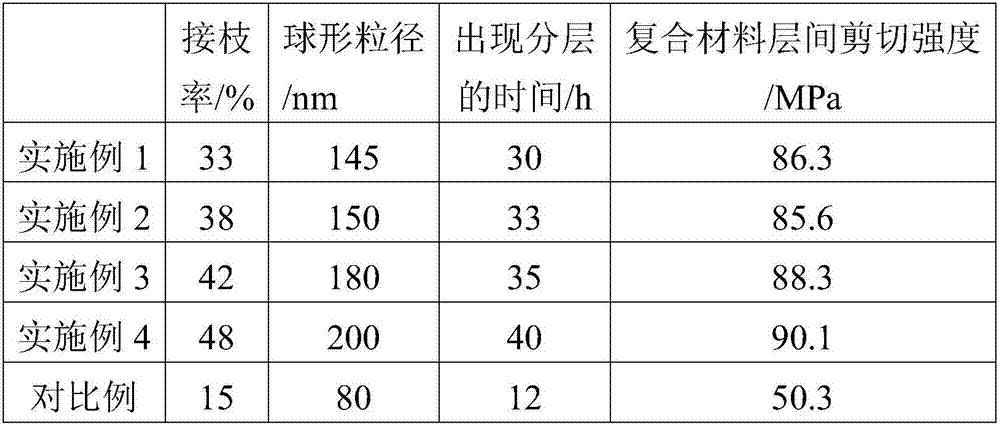

Examples

Embodiment 1

[0023] A carbon fiber / silicon dioxide hybrid material, the preparation method of which is:

[0024] (1) Put 5 parts of carbon fibers into a mixed solution (mass ratio 1:1) of 50 parts of concentrated sulfuric acid (mass concentration 80%) and concentrated nitric acid (mass concentration 65%), and heat at 45°C for 45 minutes to prepare Get carboxylated carbon fiber;

[0025] (2) Add 1 part of carboxylated carbon fiber into the flask, then add 5 parts of polyacrylic acid, 5 parts of catalyst dicyclohexylcarbodiimide, and 100 mL of tetrahydrofuran, mix ultrasonically for 30 minutes, vacuumize the flask and fill it with nitrogen, under the protection of nitrogen Magnetic stirring at 50°C for 24 hours, drying the product at 60°C to obtain polyacrylic acid-grafted carbon fibers;

[0026] (3) Add 1 part of polyacrylic acid grafted carbon fiber prepared in step (2) into the flask, add 5 parts of dicyclohexylcarbodiimide, 0.5 part of 4-dimethylaminopyridine, 5 parts of silane coupling...

Embodiment 2

[0030] A carbon fiber / silicon dioxide hybrid material, the preparation method of which is:

[0031] (1) Put 7.5 parts of carbon fiber into a mixed solution (mass ratio 1:2) of 112.5 parts of concentrated sulfuric acid (mass concentration 85%) and concentrated nitric acid (mass concentration 68%), and heat at 47.5°C for 67.5min, Prepare carboxylated carbon fibers;

[0032] (2) Add 2.5 parts of carboxylated carbon fibers into the flask, then add 7.5 parts of polyacrylic acid, 7.5 parts of catalyst dicyclohexylcarbodiimide, and 125 mL of tetrahydrofuran, mix ultrasonically for 45 minutes, vacuumize the flask and fill it with nitrogen, under the protection of nitrogen Stir magnetically at 55°C for 36 hours, and dry the product at 60°C to obtain polyacrylic acid-grafted carbon fibers;

[0033] (3) Add 3 parts of polyacrylic acid grafted carbon fibers prepared in step (2) into the flask, add 7.5 parts of dicyclohexylcarbodiimide, 0.75 parts of 4-dimethylaminopyridine, and 7.5 parts...

Embodiment 3

[0037] A carbon fiber / silicon dioxide hybrid material, the preparation method of which is:

[0038] (1) Put 10 parts of carbon fiber into a mixed solution (mass ratio 1:3) of 200 parts of concentrated sulfuric acid (mass concentration 98%) and concentrated nitric acid (mass concentration 70%), and heat it at 50°C for 90 minutes to prepare Get carboxylated carbon fiber;

[0039] (2) Add 5 parts of carboxylated carbon fibers into the flask, then add 10 parts of polyacrylic acid, 10 parts of catalyst dicyclohexylcarbodiimide, and 150 mL of tetrahydrofuran, mix ultrasonically for 60 minutes, vacuumize the flask and fill it with nitrogen, under the protection of nitrogen Stir magnetically at 60°C for 48 hours, and dry the product at 60°C to obtain polyacrylic acid-grafted carbon fibers;

[0040] (3) Add 5 parts of polyacrylic acid grafted carbon fiber prepared in step (2) into the flask, add 10 parts of dicyclohexylcarbodiimide, 1 part of 4-dimethylaminopyridine, 10 parts of silan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com