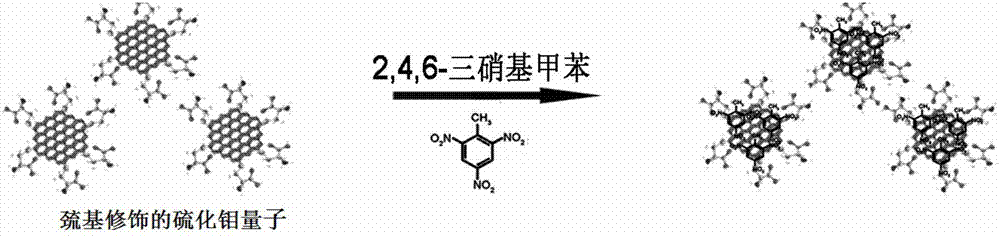

Sulfydryl-modified molybdenum sulfide quantum dot, preparation method of sulfydryl-modified molybdenum sulfide quantum dot and detection method of 2,4,6-trinitrotoluene

A technology of trinitrotoluene and sulfhydryl modification, which can be used in chemical instruments and methods, measuring devices, fluorescence/phosphorescence, etc., and can solve problems such as the existence of molybdenum oxide sulfide quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

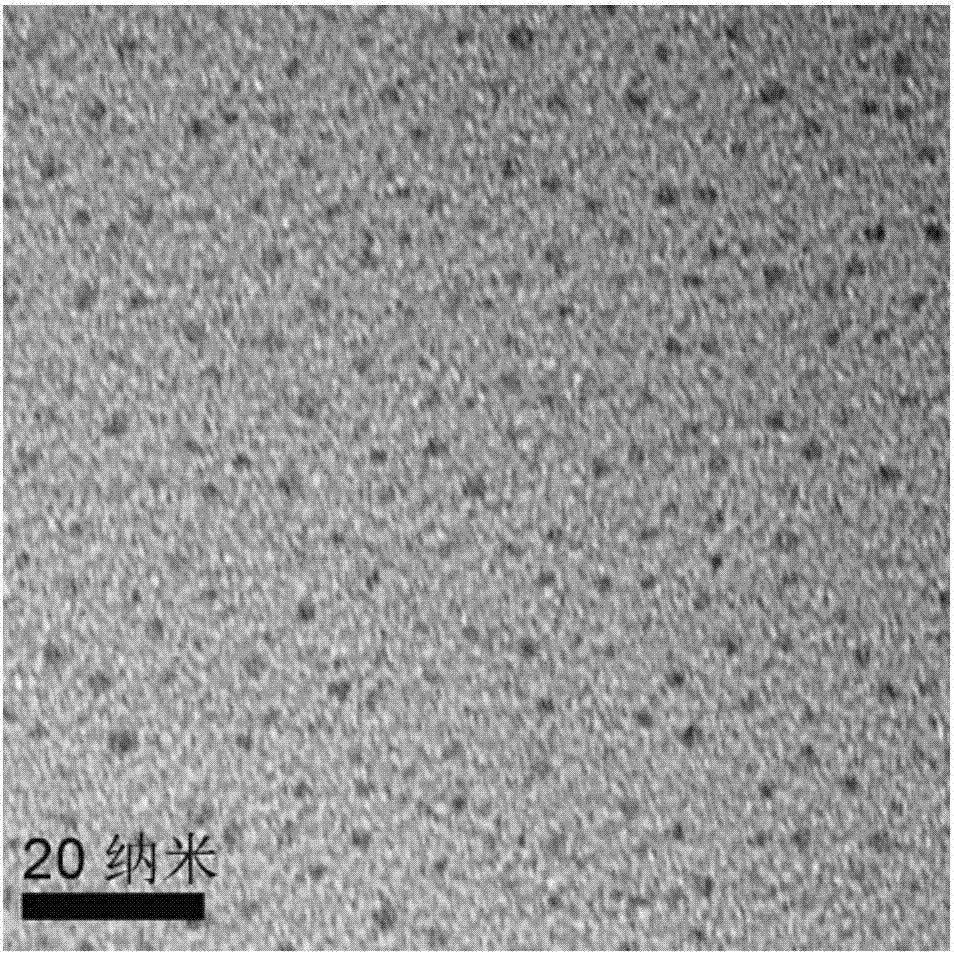

Image

Examples

preparation example Construction

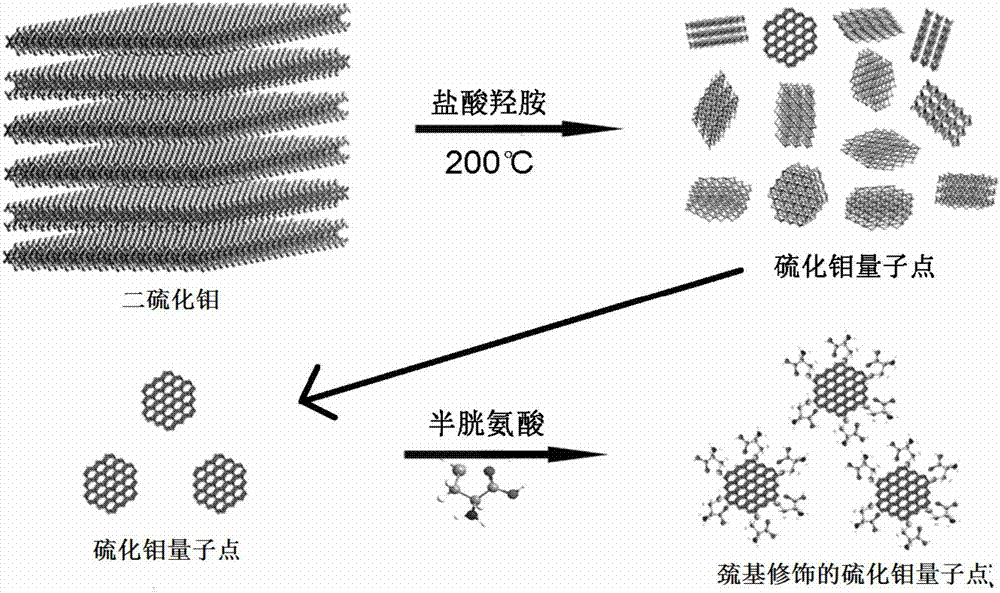

[0031] Among the present invention, a kind of preparation method of molybdenum sulfide quantum dots modified by mercapto group is provided, wherein, the preparation method comprises:

[0032] 1) first mix hydroxylamine hydrochloride, molybdenum disulfide and an inorganic solvent, then perform heat treatment, and then carry out centrifugal purification to obtain molybdenum sulfide quantum dots;

[0033] 2) Mixing the molybdenum sulfide quantum dots, the mercapto-containing compound and an inorganic solvent, and then performing a contact reaction to prepare mercapto-modified molybdenum sulfide quantum dots.

[0034] In the above-mentioned preparation method, the amount of each component can be selected in a wide range, as long as the molybdenum disulfide is sufficiently stripped so that the heat treatment reaction can proceed; but in order to further improve the molybdenum disulfide stripping efficiency As for the production yield of quantum dots, preferably, relative to 1 part ...

Embodiment 1

[0053] First, mix hydroxylamine hydrochloride, molybdenum disulfide and water according to the weight ratio of 1:0.2:90, transfer it to a high-pressure reactor, heat it in water at 180°C for 10 hours, and then select a rotation speed of 11,000 rpm for 15 minutes to obtain molybdenum sulfide quantum dots;

[0054] Next, mix the purified molybdenum sulfide quantum dots with cysteine at a weight ratio of 0.03:0.6, then add water, conduct a contact reaction at 60°C for 10 hours, and then transfer to a dialysis bag with a molecular weight of 1000 for dialysis for 12 hours , that is, the sulfhydryl-modified molybdenum sulfide quantum dots were prepared, denoted as A1.

Embodiment 2

[0056] First, mix hydroxylamine hydrochloride, molybdenum disulfide and water according to the weight ratio of 1:0.3:95, transfer to a high-pressure reactor, heat water at 190°C for 11 hours, and then select a speed of 11,000rpm for centrifugal purification for 15 minutes to obtain molybdenum sulfide quantum dots; then, The purified molybdenum sulfide quantum dots and cysteine were mixed according to the weight ratio of 0.04:0.7, then water was added, and the contact reaction was carried out at 80°C for 11 hours, and then transferred to a dialysis bag with a molecular weight of 1000 for dialysis for 12 hours. The mercapto-modified molybdenum sulfide quantum dots were prepared, denoted as A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com