Device of achieving denitration and multistage ammonia spray of SCR (selective catalytic reduction) flue gas and flue gas denitration method

A flue gas and flue gas inlet technology, which is applied in the field of power station environmental protection, can solve the problems of reducing agent ammonia concentration deviation, ammonia concentration deviation, etc., and achieve the effects of uniform ammonia spraying, short transformation period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

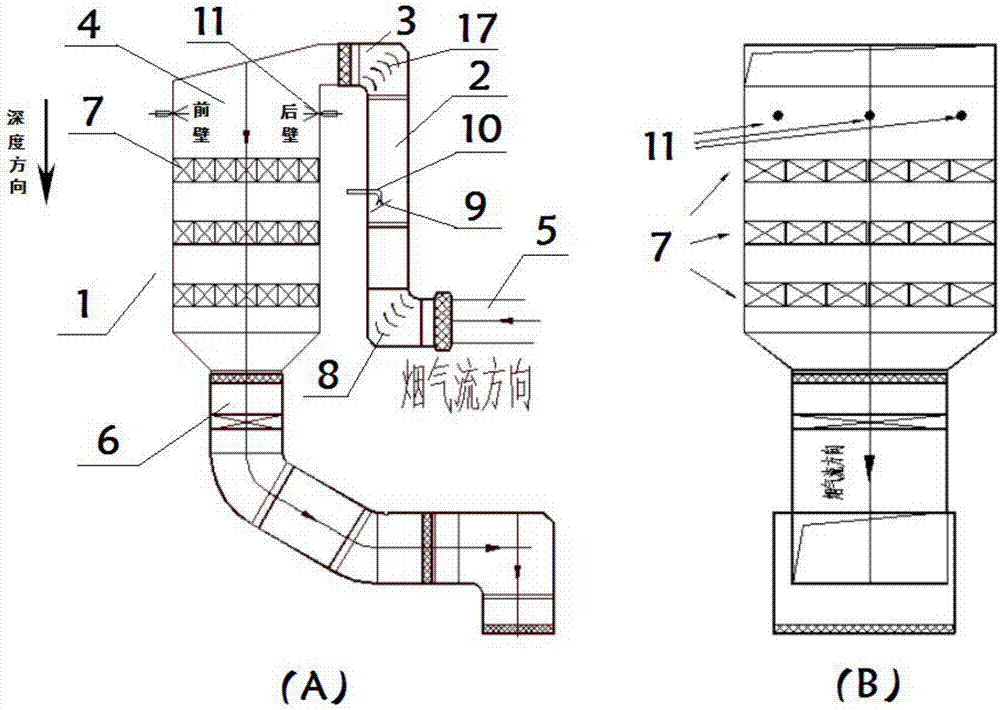

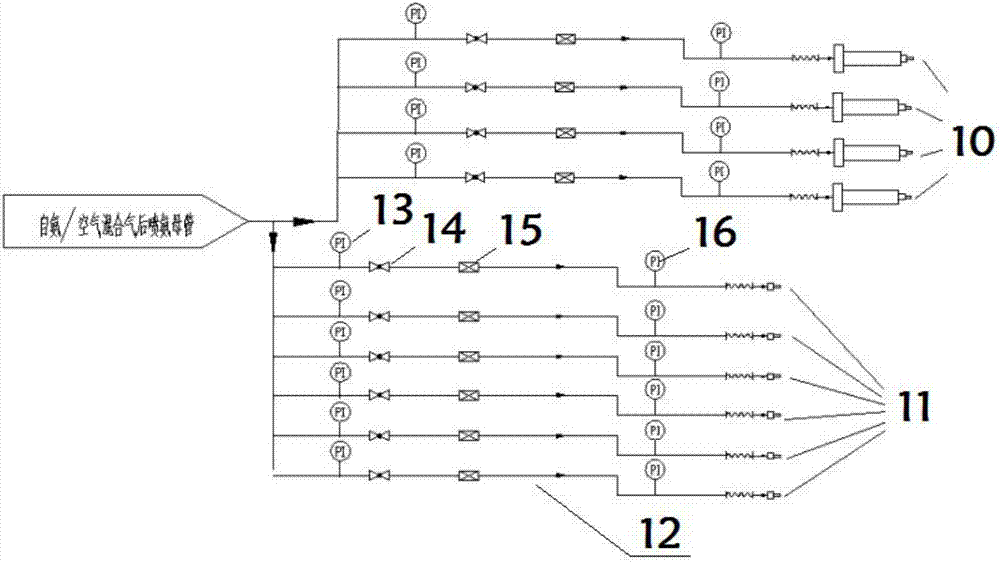

[0028] like figure 1 and 2 A graded ammonia injection SCR flue gas denitrification reactor is shown, including a reactor body 1, and the reactor body 1 sequentially includes a first vertical section 2, a horizontal connecting section 3 and a second vertical section 4 according to the flow direction of the flue gas A horizontal flue gas inlet pipe 5 is provided before the first vertical section 2, three layers of horizontally arranged catalysts 7 are arranged in the second vertical section 4, and a flue gas outlet pipe 6 is provided behind the second vertical section 4. One vertical section 2 is provided with a first-stage mixing and uniform distribution system, and the second vertical section 4 is provided with a second-stage mixing and uniform distribution system. A corner deflector 17 is provided at the corner connecting the first vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com