Graphene filter composite membrane and preparation method thereof

A graphene and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of non-degradable and easy-to-foul membranes, and achieve simple operation, strong controllability, and improved interception performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

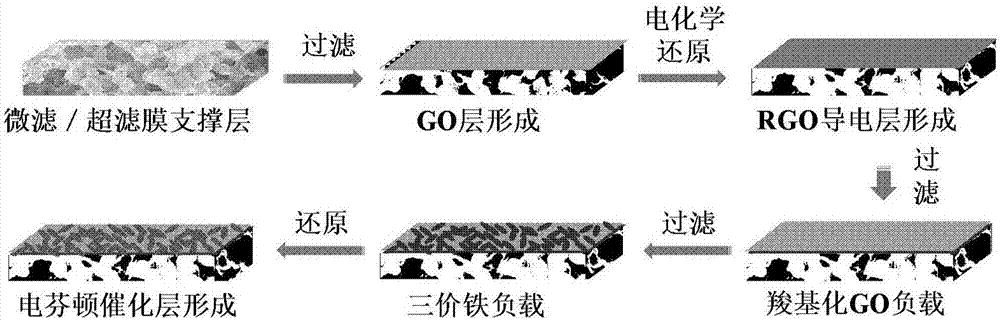

[0033] The invention discloses a preparation method of a graphene filter composite membrane, comprising:

[0034] Carboxylated graphene oxide is filtered onto the membrane support layer by suction filtration or cross-flow filtration to form a composite membrane support layer;

[0035] The composite membrane support layer formed in the above steps is used to filter the ferric chloride solution, and the electro-Fenton catalyst layer containing ferrous iron is reduced to form an electro-Fenton catalytic layer, so as to complete the preparation of the graphene filter composite membrane.

[0036] Since the electro-Fenton catalytic layer contains ferrous compounds, it has a certain interception effect on refractory pollutants, and can decompose refractory pollutants in situ, thus solving the problem that membrane technology cannot reduce the toxicity of refractory pollutants , and reduce membrane fouling. At the same time, since there is a composite membrane support layer under the...

Embodiment 1

[0058] Such as figure 1 As shown, a flat polytetrafluoroethylene (PTFE) microfiltration membrane with a pore size of 0.45 μm was used as the membrane support layer. Specifically include the following steps:

[0059] Step 1. Under the conditions of room temperature 25°C, transmembrane pressure difference 0.2MPa, and cross flow rate 1.5L / min, load 2.02g / L GO dispersion on the membrane support layer, and dry it at 40°C.

[0060] Step 2, carry out electrochemical reduction to the GO membrane of above-mentioned oven dry, wherein, use the NaCl solution of 0.5M as electrolytic solution, react 24h, control reaction potential at-1.0V (relative to reference electrode Ag / AgCl), obtain RGO conductive layer.

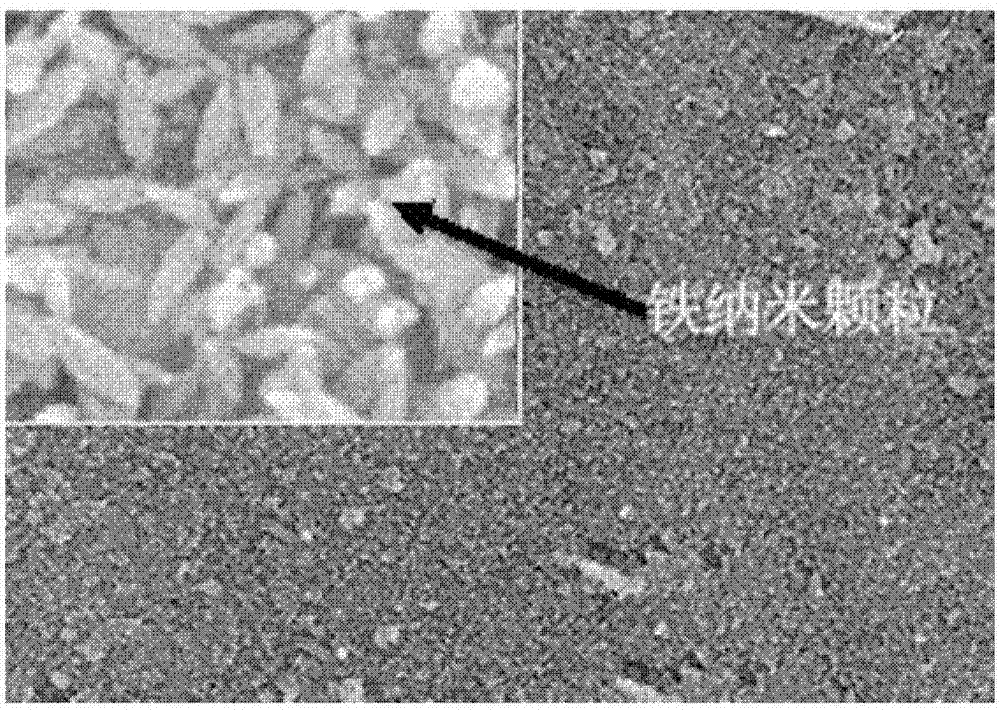

[0061] Step 3. Prepare carboxylated GO solution, load the carboxylated GO solution on the RGO conductive layer by cross-flow filtration method, the dosage is 0.1g / cm 2 , and then filter sodium hydroxide solution, sufficient ultrapure water and ferric chloride solution through the ...

Embodiment 2

[0072] This example proposes a method for preparing a graphene filtration composite membrane, which is basically the same as that of Example 1, the only difference being that the membrane support layer of this example uses a PTFE microfiltration membrane with a pore size of 0.22 μm. The effect of the graphene filtration composite membrane obtained in this embodiment to degrade pollutants is basically the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com