A kind of preparation method of single-atom dispersed palladium-based catalyst and its catalytic application

A technology of atomic dispersion and catalyst, which is applied in the application field of single-atom dispersion palladium-based catalyst and its catalytic alkyne selective hydrogenation reaction, can solve the problems of low selectivity and low activity, and achieve improved selectivity and activity, high catalytic Effect of activity and selectivity, excellent catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

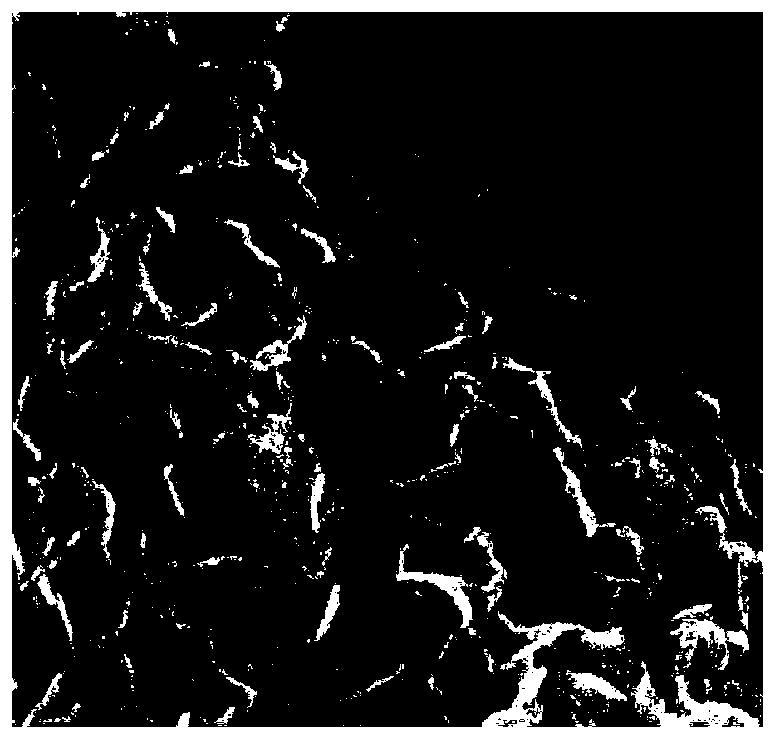

Image

Examples

Embodiment 1

[0026] In this example, ZnCr-LDH was prepared by the double-drop method. The molar ratio of Zn / Cr is 2 / 1; first weigh 0.66mol of Zn(NO 3 ) 2 ·6H 2 O, 0.33mol Cr(NO 3 ) 3 9H 2 0, and measure 60ml of deionized water with a graduated cylinder to fully mix with the said metal salt, and put it into an ultrasonic cleaner and let it stand for 10min to achieve sufficient dissolution. In addition, weigh 0.30mol of NaOH and 0.25mol of NaOH 2 CO 3 Put it into a clean beaker, stir it with 80ml of deionized water to dissolve it, and put it into an ultrasonic cleaner for 10 minutes to make it fully dissolved; first add 150ml of deionized water to the three-necked flask; then put the sonicated alkali The solution and the salt solution were respectively added to two constant pressure dropping funnels, and added dropwise to the 150ml carbon dioxide-free aqueous solution in the three-necked flask, and the pH of the mixed solution was controlled to be stable at 10, and then the resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com