Mesoporous Fe-based MOF@AgI high-efficiency composite visible light photocatalysis material, and preparation method and application thereof

A photocatalytic material and visible light technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to increase specific surface area, increase absorption rate, and enhance visible light Effect of photocatalytic degradation of organic dye activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

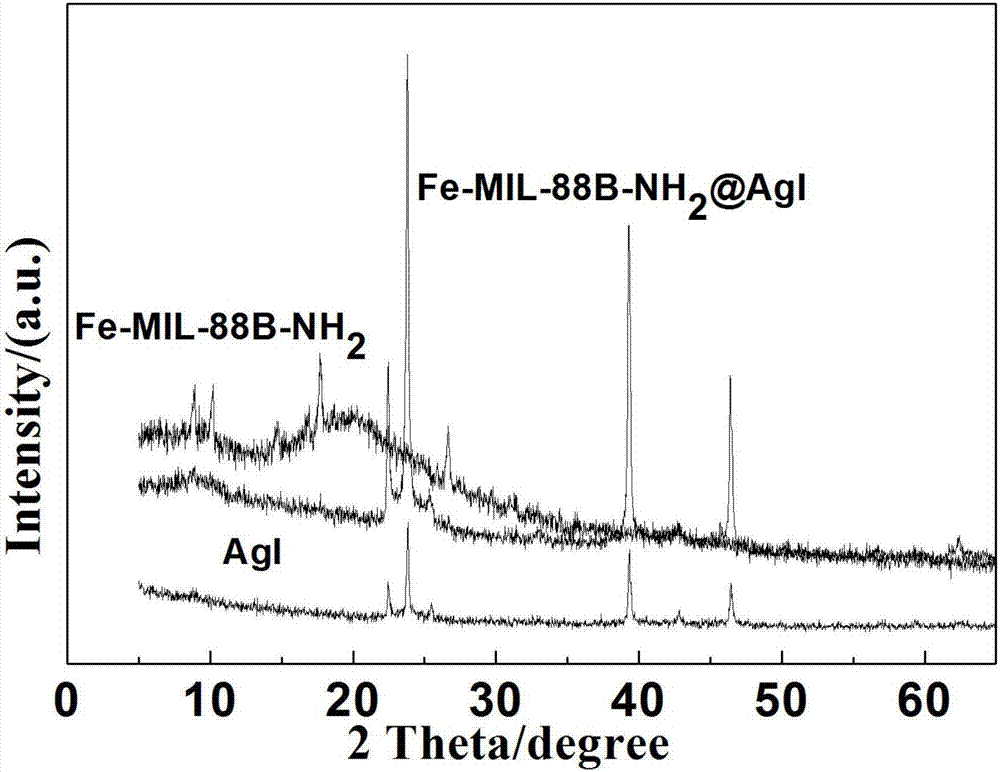

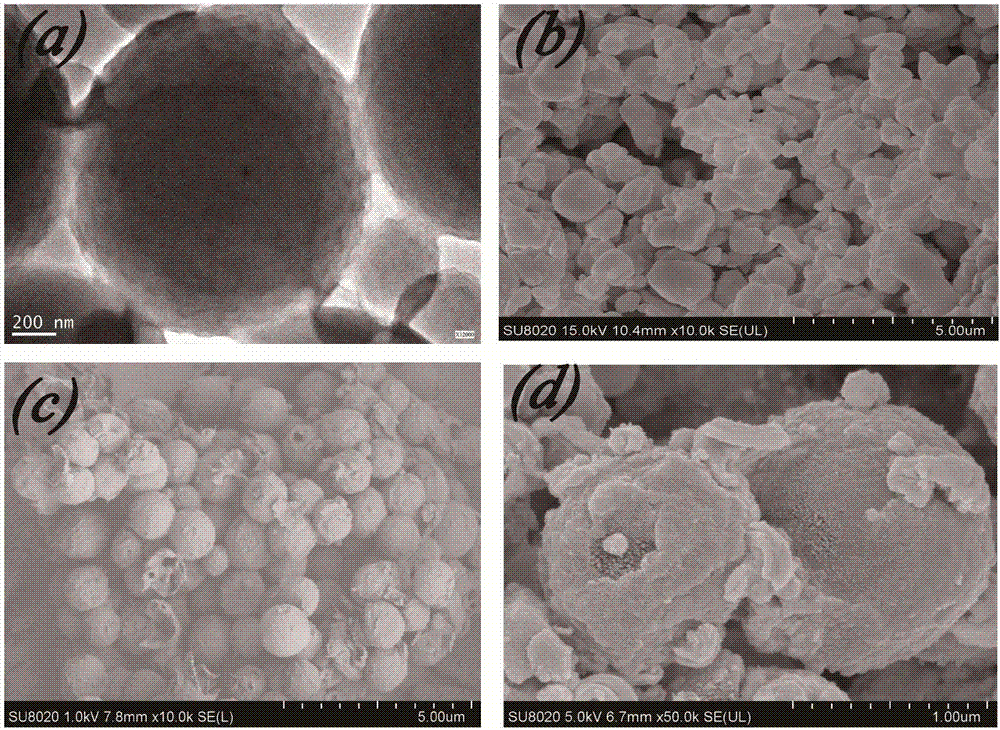

[0033] This example prepares mesoporous Fe-MIL-88B-NH according to the following steps 2 @AgI efficient composite visible light photocatalytic material:

[0034] 1. Preparation of polystyrene template

[0035] Dissolve 2.040g of stabilizer polyvinylpyrrolidone in 60.147g of absolute ethanol, transfer the resulting solution into a three-necked flask, stir for 0.5h under nitrogen protection and a constant temperature of 60°C, and then dissolve 0.260g of azobisiso Butyronitrile and 25.214g of styrene, which was sealed and stored in closed light after vacuum distillation at 60°C, were added to the above system, and then 9.523g of deionized water was added to the system, the temperature was raised to 70°C, and the temperature was reacted for 12 hours. The obtained product was cooled to Centrifuge at room temperature at a speed of 6000 r / min, wash twice with ethanol, and dry under vacuum at 60° C. to obtain white polystyrene template powder.

[0036] 2. Sulfonation of polystyrene ...

Embodiment 2

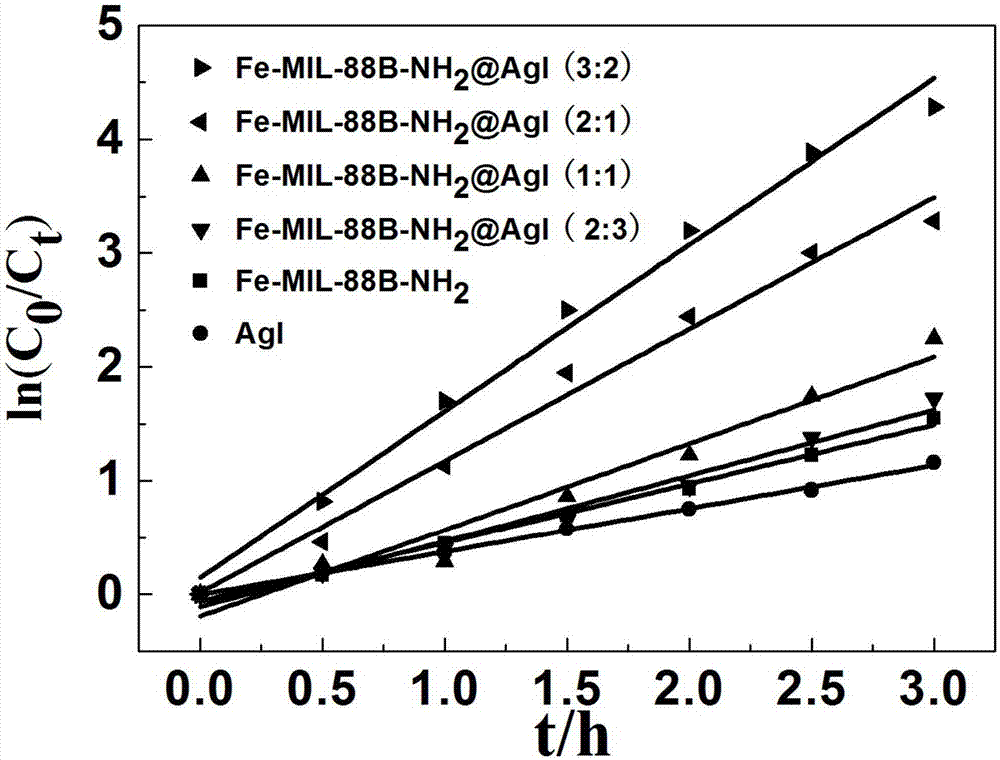

[0046] This embodiment prepares Fe-MIL-88B-NH in the same manner as in Example 1 2 @AgI high-efficiency composite visible light photocatalytic material, the only difference is: AgNO in step 4 3 The volume of the solution and the KI solution was changed to 7.37mL and 5.65mL respectively, and the resulting product Fe-MIL-88B-NH 2 The photocatalytic properties of @AgI(2:1) are as follows image 3 shown.

Embodiment 3

[0048] This embodiment prepares Fe-MIL-88B-NH in the same manner as in Example 1 2 @AgI high-efficiency composite visible light photocatalytic material, the only difference is: AgNO in step 4 3 The volume of the solution and the KI solution was changed to 22.0mL and 17.0mL respectively, and the resulting product Fe-MIL-88B-NH 2 The photocatalytic performance of @AgI(2:3) as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com