Grain refiner for ferritic stainless steel continuous casting and preparing method and using method of grain refiner

A grain refiner, stainless steel technology, applied in the field of grain refiner for ferritic stainless steel continuous casting, to achieve the effect of significant grain refinement and reduction of columnar crystal ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the grain refiner for continuous casting of ferritic stainless steel provided by the embodiment of the present invention specifically includes the following steps:

[0023] (1) Abrasives: Grinding the large-grained TiC prepared by the carbothermal reduction method in a planetary mill until the average particle size is less than 1 μm to obtain micron-sized TiC powder;

[0024] Carbothermal reduction method: with TiO 2 and carbon black as raw materials, after high-energy ball milling, put it into a tube furnace protected by argon flow and heat it to 1259 ° C ~ 1500 ° C, and keep it for 1 hour. As a result, a near-stoichiometric TiC powder with a grain size of about 80 nm was obtained.

[0025] Grinding: the rotation speed of the ball mill is 425r / min, and the ball milling time is 25min.

[0026] Planetary Mill Model: QMSB-4 Planetary High Energy Ball Mill

[0027] (2) Mixing: Weigh the obtained micron-sized TiC powder and Fe powder with a part...

Embodiment 1

[0034] Effect of grain refiner on microstructure of 430L ferritic stainless steel

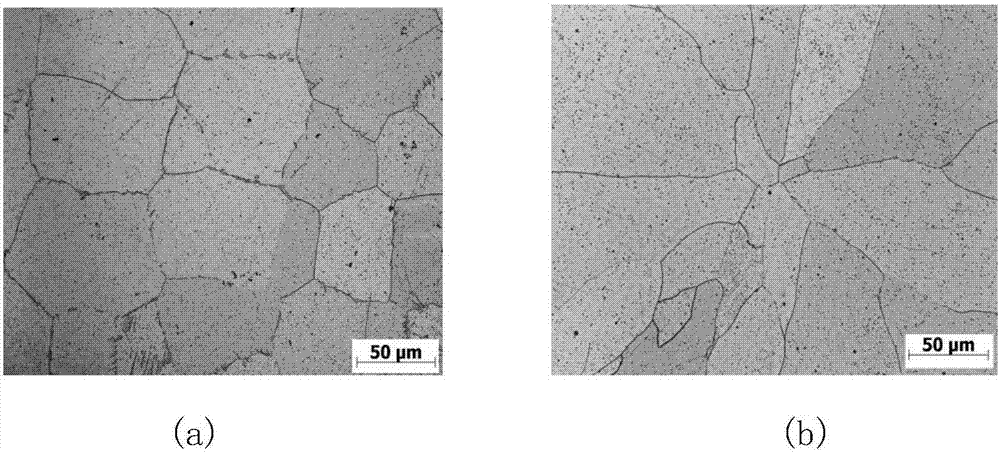

[0035] Such as figure 1 As shown, from the metallographic structure, it can be found that TiC as a grain refiner can significantly increase the ratio of equiaxed grains in the steel structure, and the number of small grains increases. When the TiC content is 0.03%, the refining effect is the best. When When the TiC content continues to increase, the refinement effect basically does not change.

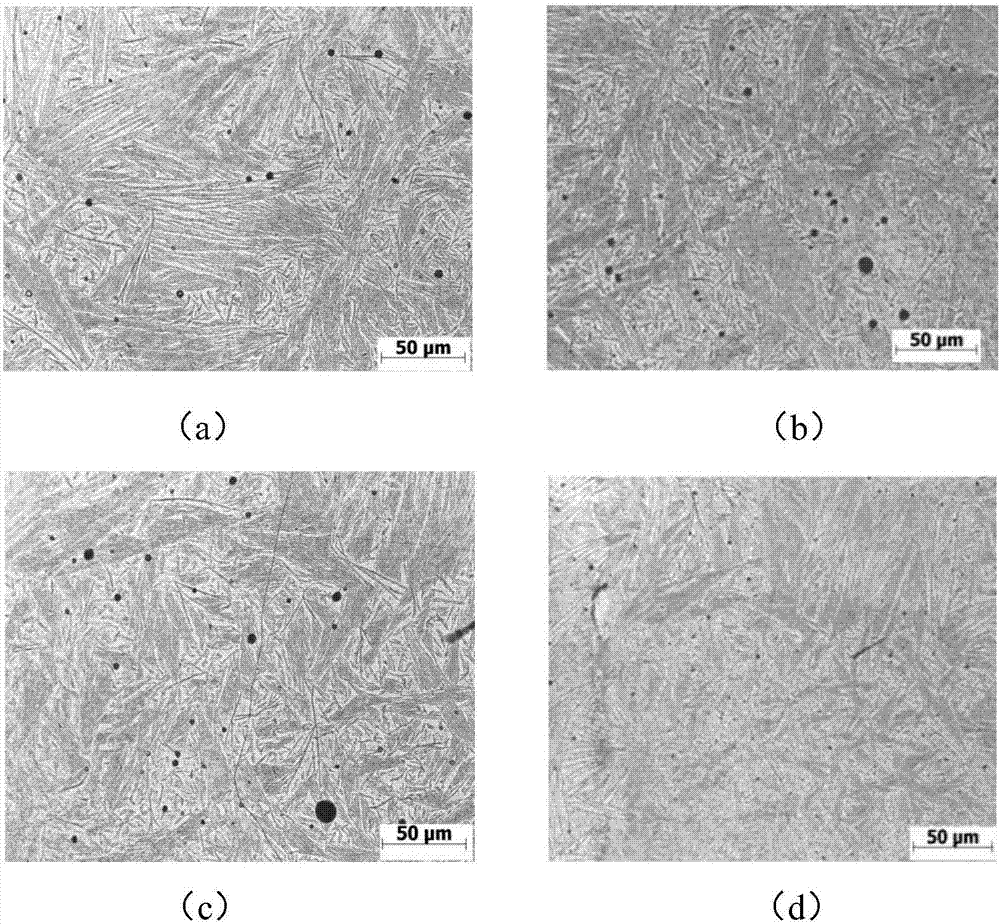

[0036] From figure 2It can be seen from the figure that the number of acicular ferrite increases with the increase of TiC content, and the size decreases continuously. When the TiC content reaches 0.03%, it presents the optimal state, and the acicular ferrite is fine and dense, showing the split grain State, play a role in refining the grain. When the amount of TiC added reaches 0.05%, the change of ferrite morphology and quantity is not obvious, which is basically similar to that of 0.03%.

Embodiment 2

[0038] Effect of grain refiner on grain size of 430L ferritic stainless steel

[0039] In the continuous casting tundish, a grain refiner was thrown into the molten steel, and its addition amount was 300 g per ton of steel. The comparison example was 430L continuous casting molten steel without throwing the grain refiner. After the smelted cast steel sample is cut, coarsely ground, finely ground, and polished, the grain boundaries are corroded. The corrosion solution is 10% oxalic acid solution for electrolysis, the corrosion voltage is 5V, and the corrosion time is 40-60s.

[0040] figure 1 (a), figure 1 (b) Typical metallographic pictures of steel samples with TiC as grain refiner and steel samples without grain refiner. Carl Zeiss metallographic microscope was used for observation, and the intercept point method in "GBT6394-2002 Metal Average Grain Size Determination Method" was used to obtain the grain size of samples with different components and contents, as shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com