Combined purification method of o/p-chlorobenzaldehyde rectification raffinate and process wastewater

A p-chlorobenzaldehyde and rectification technology, which is applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problems of high process energy consumption, difficulty in industrialization, and high cost, and achieve low energy consumption and low cost. cost, the effect of achieving heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

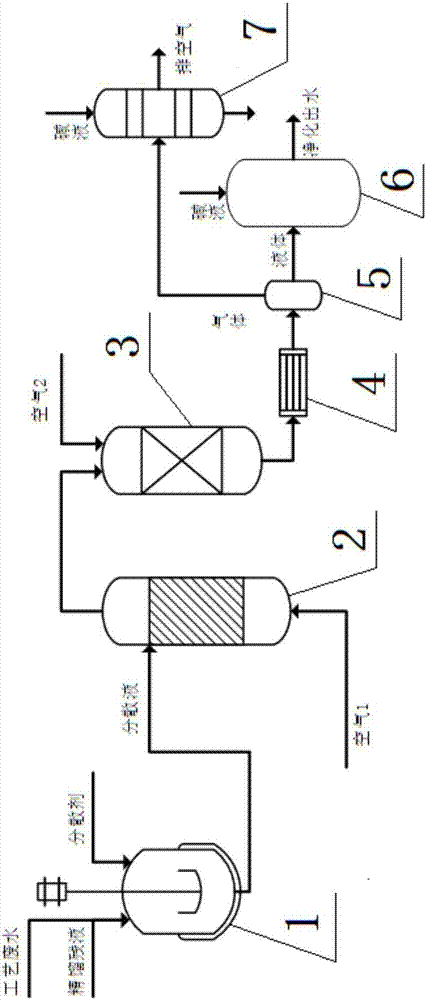

Image

Examples

Embodiment 1

[0033] Get 500mL of o-chlorobenzaldehyde rectification raffinate, add 0.05g propylene glycol fatty acid ester (dispersant) and 2823mL process waste water, disperse 40min in dispersing kettle under 50 ℃, obtain the dispersion liquid that viscosity is 12mPa s; The calorific value of the liquid is 30000kJ / kg, and the COD in the process wastewater is 17000mgO 2 / L.

[0034] Catalytic cracking oxidation catalyst in fluidized bed is PtO 2 -MnO 2 / ZSM-5, the catalyst is prepared by spray drying method, the preparation method: mix 18gH 2 PtCl 6 and 400ml of 50% Mn(NO 3 ) 2 Dissolve the solution in 300ml of water, immerse 1000g of ZSM-5 molecular sieve in the above aqueous solution for 12 hours, add 100g of silica sol and stir evenly, spray into a spray dryer, dry at 120°C, and roast at 550°C for 3h to obtain a composite oxide catalyst , the catalyst particle size is 60-200μm, PtO 2 The loading amount is 1%, MnO 2 The loading capacity is 15%;

[0035] The catalytic oxidation c...

Embodiment 2

[0038] Take 500mL of rectification raffinate of o-chlorobenzaldehyde, add 0.07g glyceryl monostearate (dispersant) and 2000mL process wastewater, and disperse in a dispersion kettle for 50min at 50°C to obtain a dispersion with a viscosity of 23mPa·s; The heat value of distillation raffinate is 32000kJ / kg, and the COD in process wastewater is 18000mgO 2 / L.

[0039] Catalytic cracking oxidation catalyst in fluidized bed is PtO 2 -CrO 3 / Y, the catalyst is prepared by spray drying method, the preparation method: mix 18gH 2 PtCl 6 and 263g Cr(NO 3 ) 3 9H 2 O was dissolved in 300ml water, 1000gY molecular sieve was immersed in the above aqueous solution for 12h, then 100g of silica sol was added and stirred evenly, sprayed into a spray dryer, dried at 120°C, and calcined at 550°C for 3h to obtain a composite oxide catalyst, catalyst Particle size is 60~200μm, PtO 2 The loading amount is 1%, Cr 2 o 3 10% of the load;

[0040] The catalytic oxidation catalyst used in the...

Embodiment 3

[0043] Take 500mL of rectification raffinate of o-chlorobenzaldehyde, add 0.7g glyceryl monostearate (dispersant) and 1739mL process wastewater, and disperse in a dispersing kettle for 30min at 60°C to obtain a dispersion with a viscosity of 41mPa·s; The calorific value of the distillation raffinate is 16800kJ / kg, and the COD in the process wastewater is 9000mgO 2 / L.

[0044] The catalytic cracking oxidation catalyst in the fluidized bed is Cr 2 o 3 / Y, the catalyst is prepared by spray drying method, the preparation method: 790gCr(NO 3 ) 3 9H 2 O was dissolved in 300ml of water, 1000g of Y molecular sieve was immersed in the above aqueous solution for 12h, then 100g of aluminum sol was added and stirred evenly, sprayed into a spray dryer, dried at 120°C, and calcined at 550°C for 3h to obtain a composite oxide catalyst. Catalyst particle size is 60~200μm, Cr 2 o 3 The loading capacity is 15%;

[0045] The catalytic oxidation catalyst used in the fixed bed is CuO / Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com